Method for patching side wall of dilution electric furnace

A technology for depleting electric furnaces and side walls, applied in the field of metallurgy, can solve the problems of affecting the service life of electric furnaces, high cost, rapid damage, etc., and achieve the effects of shortening the maintenance period, prolonging the service life and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A method for digging and repairing the side wall of a dilute electric furnace, specifically comprising the following steps:

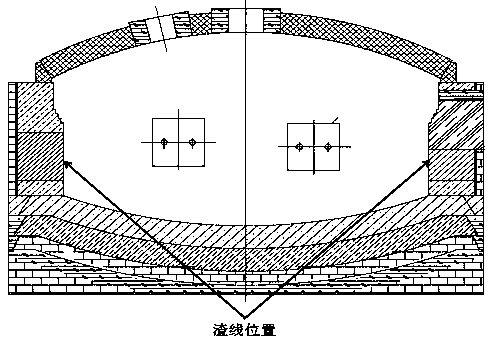

[0023] 1) Increase the temperature control in the furnace before stopping the furnace to reduce the freezing in the furnace to below the slag line.

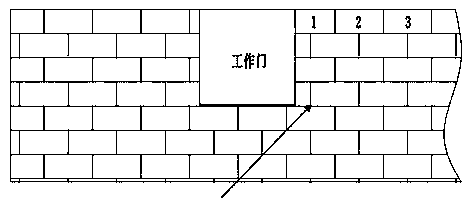

[0024] 2) After the furnace is shut down, open the working door of the side wall to cool down, remove 8 layers of refractory bricks in the working door hole, and the cooling time of the furnace shutdown is 7 days. Enter the furnace to set up a whole house of scaffolding, and lay 7000×300×40mm wooden boards on the top to ensure the safety of working in the furnace.

[0025] 3) The position of the slag line is excavated and repaired by demolition and masonry: remove the refractory brick at the position of the slag line along the lower edge of each work door, and only remove one refractory brick facing the furnace during demolition. ×150×75mm. For each demolition, remove 15 refractory bricks: remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com