Fluid stirring and purifying element with arc air channel

A technology of purification components and fluid stirring, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of poor purification effect of molten steel stirring, long cleaning time of burning oxygen, and large stress of breathable bricks, etc., to achieve The effect of reducing the probability of overall transection, avoiding excessive loss, and high blowing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

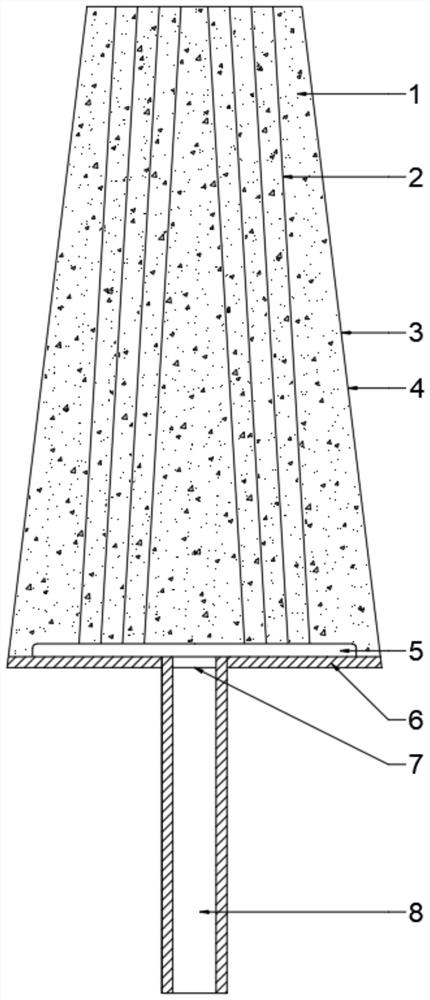

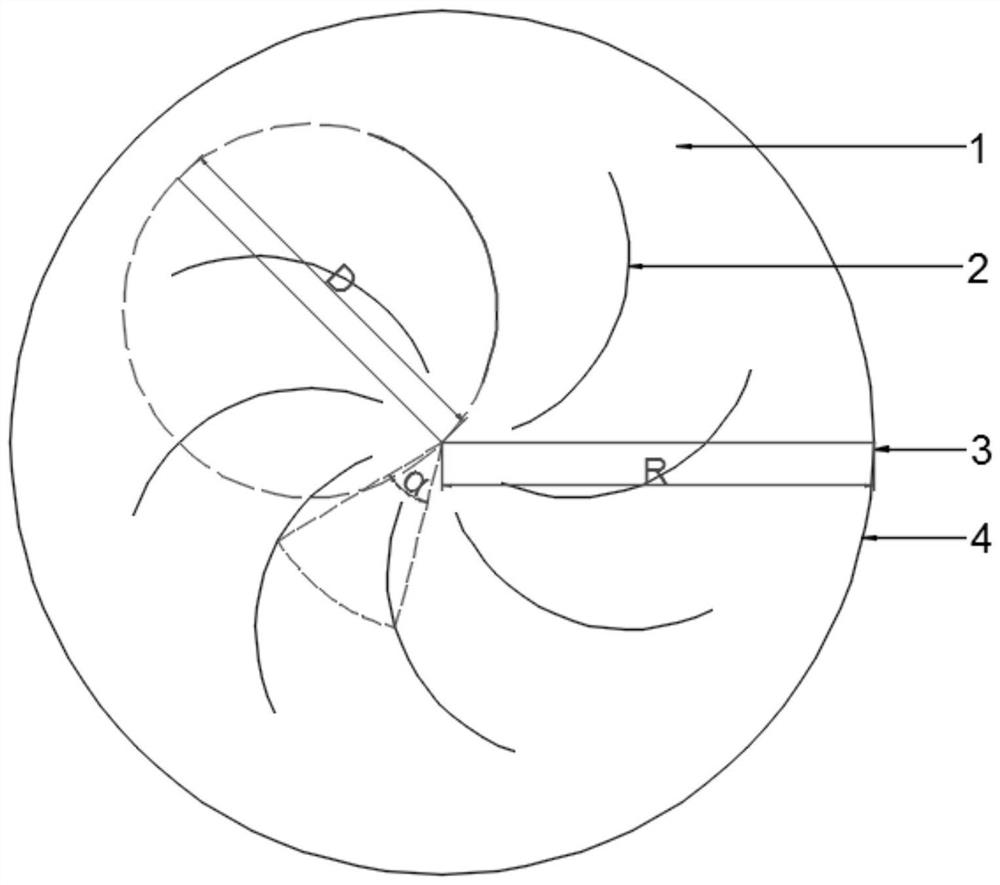

[0033] The schematic diagram of the structure of the fluid agitation and purification element with arc air channels in this embodiment is shown in figure 1 and figure 2 .

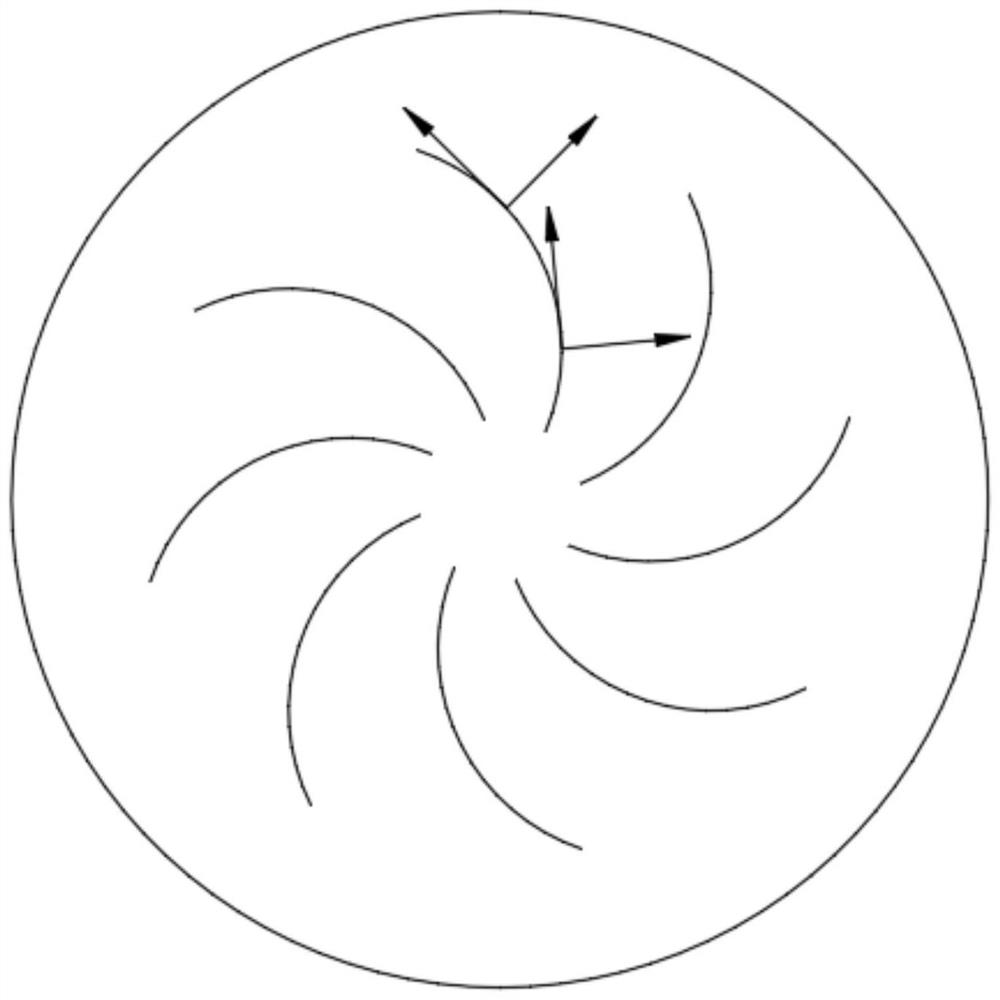

[0034] like figure 1 and figure 2 As shown, in this embodiment, the fluid agitating and purifying element with circular arc air passage includes a brick core body 1, a metal steel shell 3, a refractory mud layer 4, a metal bottom 6 and a metal tail pipe 8; the brick core body 1 has a circular The arc blowing air passage 2 and the arc blowing air passage 2 are arranged along the length direction of the brick core body 1. On any cross section of the brick core body 1: the arc blowing air passage 2 starts from the axis of the adjacent brick core body 1 The place extends toward the direction of the facade adjacent to the brick core body 1, and the shape of the arc blowing air channel 2 is an arc. The metal steel shell 3 is fixedly installed on the outer wall surface of the brick core body 1 through the re...

Embodiment 2

[0043] Compared with Embodiment 1, the structure of the fluid agitating and purifying element with circular arc air channels in this embodiment differs only in that an arc air supply channel 9 is set on the brick core body 1, and its specific schematic diagram is shown in Figure 4 and Figure 5 .

[0044] like Figure 4 As shown, in addition to the same structure as in Embodiment 1, the fluid agitation and purification element with circular arc air channels in this embodiment also has an inter-arc air supply channel 9 in the brick core body 1, and the inter-arc air supply channel 9 The first end is in fluid communication with the arc blowing air channel 2, and the second end opening of the arc air supply channel 9 is located on the upper end surface of the brick core body 1; the arc air supply channel 9 The height of the brick core body 1 where it is located is 1 / 10 of the overall height of the brick core body 1; The ratio is 0.5:10; the cross-section of the arc air supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com