Doped copper titanium oxide capacitor ceramic dielectric and producing method thereof

A doping-type, capacitive technology, applied in the direction of fixed capacitor dielectric, ceramics, fixed capacitor parts, etc., to achieve the effect of reduced reactivity, high dielectric constant, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

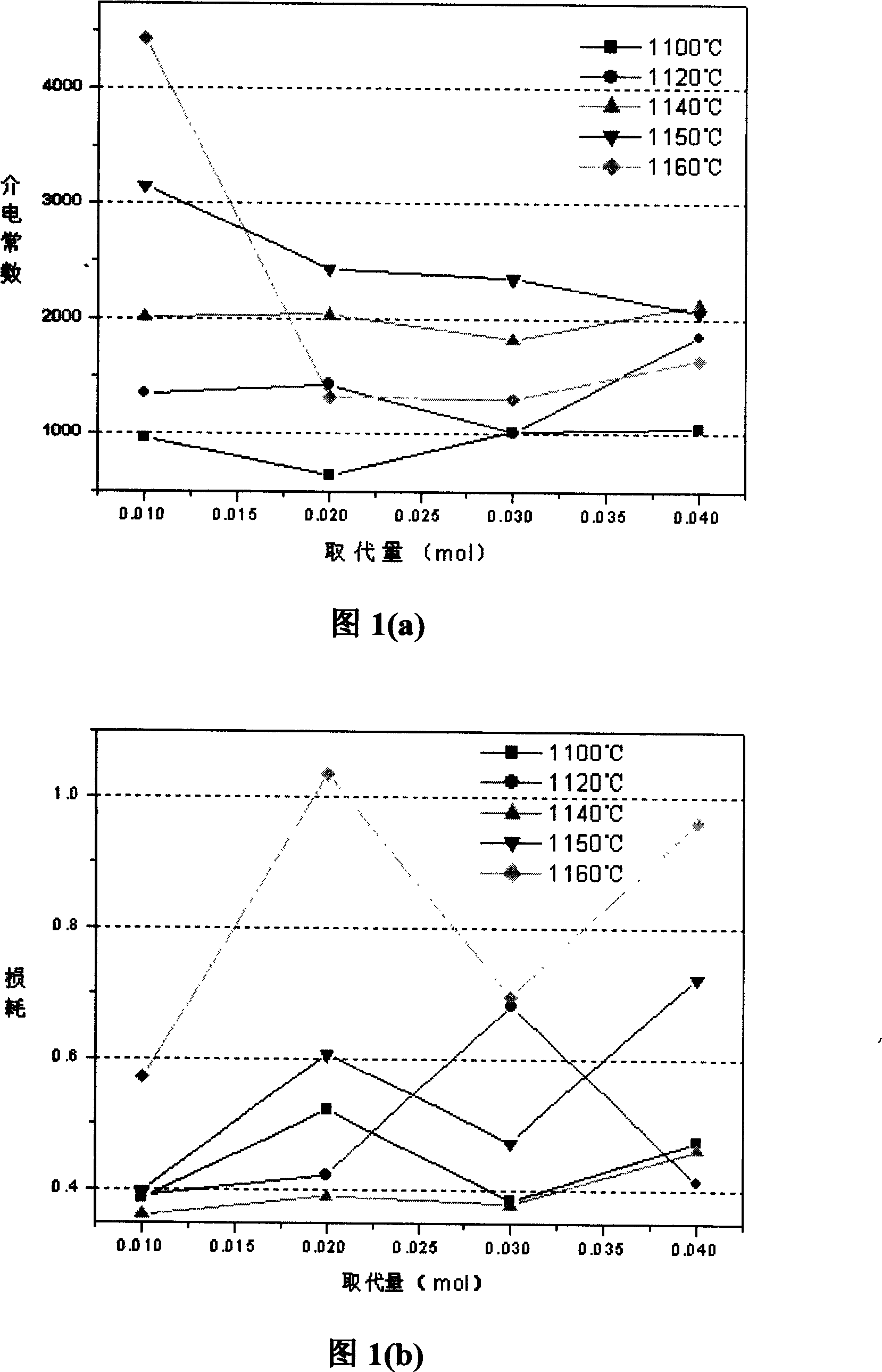

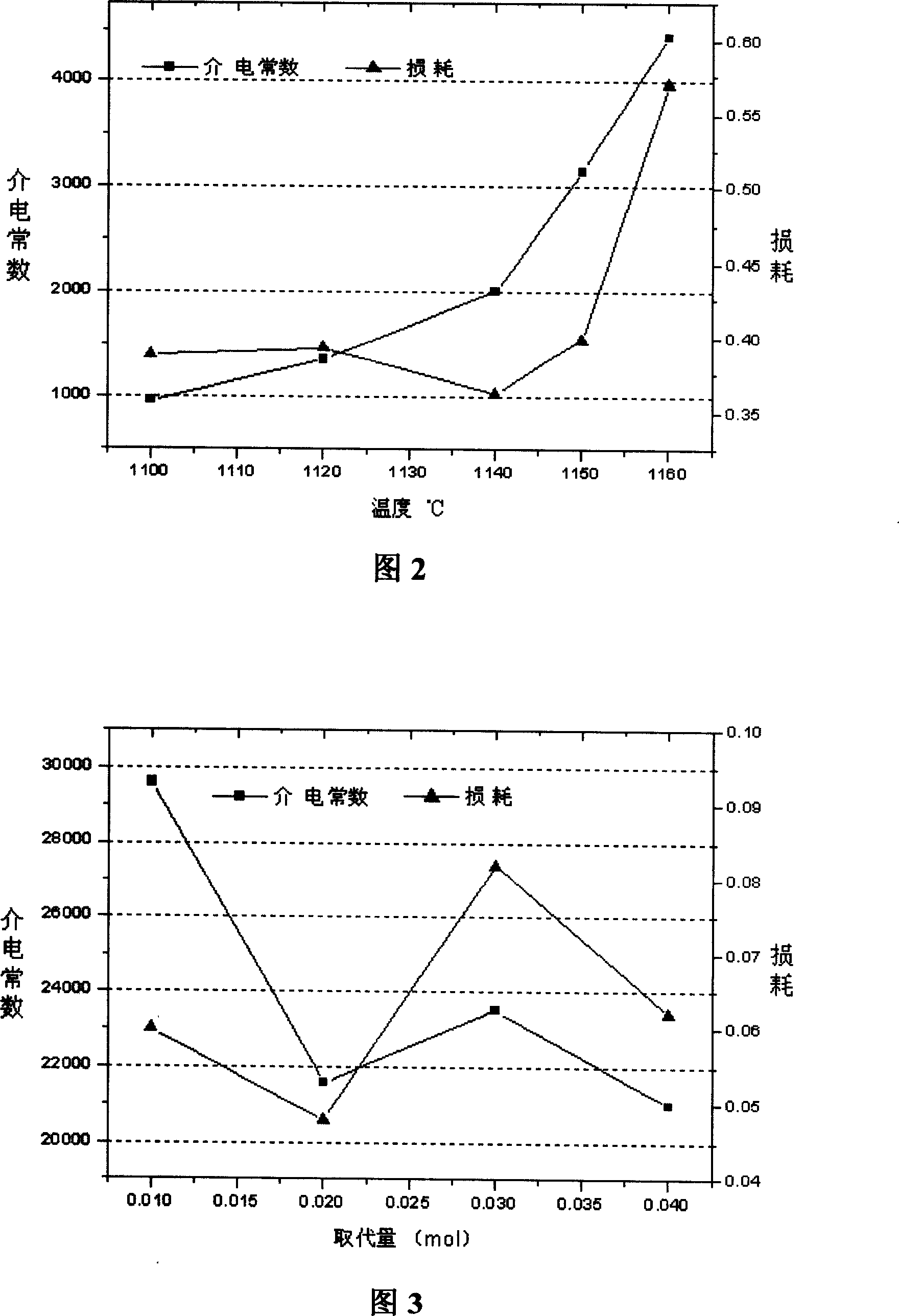

[0025] The present invention adopts solid state reaction method to prepare doped CaCu 3 Ti 4 o 12 , first select analytically pure CaCO 3 , CuO, TiO 2 as the main raw material, and mixed with an appropriate amount of SrCO 3 Form the corresponding stoichiometric formula Sr x Ca (1-x) Cu 3 Ti 4 o 12 (SCCT) powder, where x = 0.01, 0.02, 0.03, 0.04; and the samples were prepared by traditional dry pressing ceramic technology.

[0026] Sr below 0.01 Ca 0.99 Cu 3 Ti 4 o 12 As an example to illustrate its preparation process:

[0027] (1) According to Sr 0.01 Ca 0.99 Cu 3 Ti 4 o 12 The chemical proportion formula is used for batching, and the raw material powder is ground by planetary ball milling method, so that the particle size of the powder material is below 1 micron. Since the solid-phase reaction is mainly carried out by the movement and exchange of positions of the mixture lattice particles, in order to complete the solid-phase reaction as soon as possible,...

Embodiment 2

[0040] When using Na + 、K + Partial Ca substitution by unequal dielectric ions 2+ ion formation A x Ca (1-x) Cu 3 Ti 4 o 12 Ceramic material (where x=0.01, 0.02, 0.03, 0.04), when A + Ion is Na + or K + When the added amount of the ions increases, the sintering temperature of the corresponding CCTO material increases, its dielectric constant also increases, and the loss of the material decreases; but at the same time, its capacitance change rate increases. Through comparative study, it is found that the sample sintered at 1140°C and held for 24 hours can get the lowest loss, and the loss can reach less than 5% when the doping concentration is 0.02mol.

[0041] Doped with Na + 、K + Ions of equal valence replace Ca 2+ A formed by ions x Ca (1-x) Cu 3 Ti 4 o 12 Ceramic materials have high dielectric constant and small loss, and they have the same properties as doped Sr 2+ Form Sr 0.01 Ca 0.99 Cu 3 Ti 4 o 12 Similar sintering characteristics of dielectric ma...

Embodiment 3

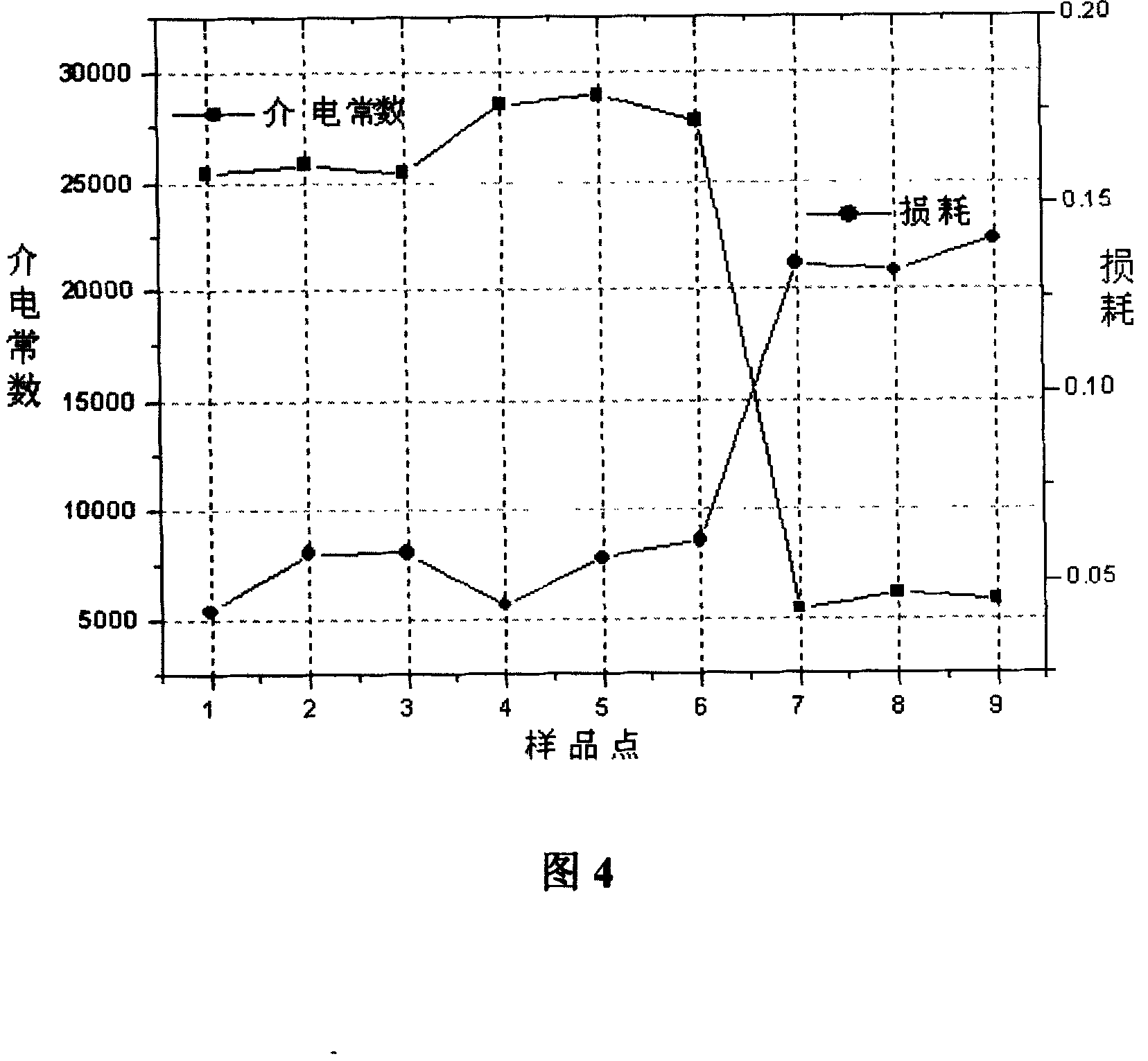

[0051] in A x Ca (1-x) Cu 3 Ti 4 o 12 Doped with 0.01mol of Sr in the ceramic material 2+ After that, the B-site dopant ion Zr was introduced 4+ to synthesize Sr 0.01 Ca 0.99 Cu 3 Ti 4(1-y) Zr 4 yO 12 , wherein y=0.01, 0.02, 0.03, 0.04; and the synthesis of the dielectric material is carried out using the similar process steps as in Example 1.

[0052] Sr below 0.01 Ca 0.99 Cu 3 Ti 3.96 Zr 0.04 o 12 As an example to illustrate its preparation process:

[0053] (1) First select analytically pure CaCO 3 , CuO, TiO 2 as the main raw material, and the analytically pure doped raw material SrCO 3 and ZrO 2 , and according to Sr 0.01 Ca 0.99 Cu 3 Ti 3.96 Zr 0.04 o 12 The stoichiometric formula carries out the batching of described raw material powder;

[0054] (2) Grinding the raw material powder by planetary ball milling so that the particle size of the powder reaches below 1 micron;

[0055](3) Preparation of the precursor: the furnace temperature is ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com