Method for measuring outer circumference and maximum and minimum diameters of cylindrical workpiece

A technology of maximum and minimum measurement methods, applied in the field of physics, can solve the problem of low accuracy of maximum and minimum diameters, and achieve the effect of good engineering application value, easy on-site implementation, and high number of measurement points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

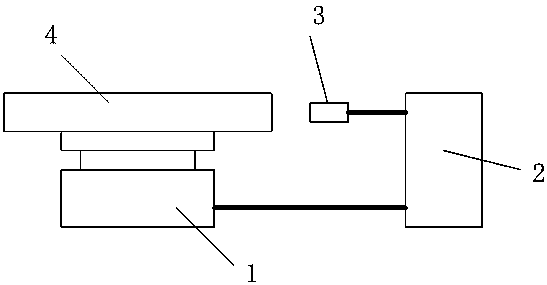

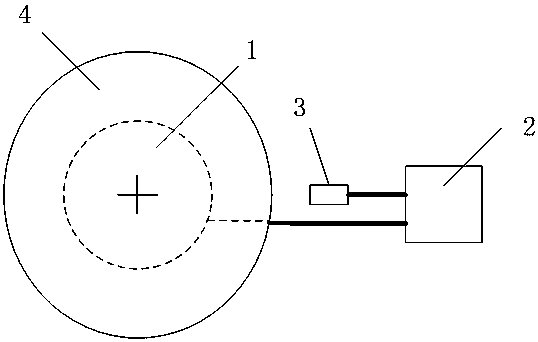

[0065] Such as figure 1 , 2 , image 3 As shown, the measuring device used in the present invention is composed of: a servo turntable 1, a control system 2, a laser displacement sensor 3, and a cylindrical workpiece 4 to be measured. The servo turntable 1 is connected to the control system 2, the laser displacement sensor 3 is connected to the control system 2, the cylindrical workpiece 4 is fixed on the servo turntable 1, and the The laser displacement sensor 3 is aligned with the cylindrical surface of the measured cylindrical workpiece 4 along the radial direction of the servo turntable 1 .

[0066] In this embodiment, the servo motor of the servo turntable 1 is specifically a Siemens 1FK7 servo motor; the control system 2 specifically uses a Siemens S7 1200PLC and S120 driver; the laser displacement sensor 3 is specifically a Panasonic HG-C1100; the cylindrical workpiece is specifically a nominal A thin-walled cylinder with a diameter of 218mm;

[0067] In this embodim...

Embodiment 2

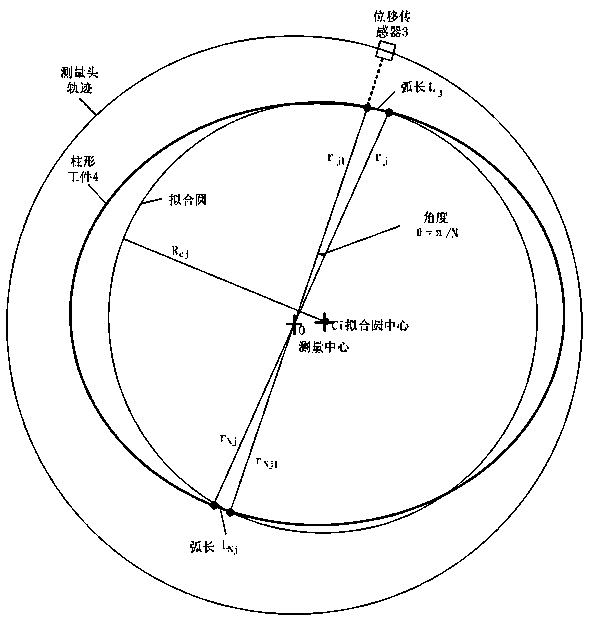

[0107] Such as Figure 4 Shown, the fitting radius formula that the present invention adopts can be described as following geometry problem:

[0108] Known: A, B, C, and D share a circle, and the center of the circle is assumed to be C j ; AC, BD intersect at O; ∠AOB=θ; AO=r j ;CO=r Nj ;BO=r j1 ;DO=r Nj1 ;

[0109] Seek: Circle C j The radius R cj

[0110] Solution: pass O, C j Circle C j The diameter EF, let |OC j |=d, easy to know So there are:

[0111]

[0112] That is:

[0113] Similarly, there are:

[0114] In the case that A, B, C, and D are not co-circular, it can be fitted by taking the average of the sum of the above two formulas to obtain:

[0115]

[0116] which is:

[0117] by C j Draw the vertical line C of AC and BD respectively j G, C j H, easy to know O, G, H, C j Co-circle, set circle Q, it is easy to know that the diameter of circle Q is d.

[0118] Construct a circle Q with diameter GI through G, so there is ∠GIH=∠GOH=θ;

...

Embodiment 3

[0132] Example 3 Calibration

[0133] Calibration work should be done before the method of the present invention is put into practical application. The calibration work is to measure after the installation of the equipment is completed: the distance D between the zero position of the displacement sensor and the center of the servo shaft 0 .

[0134] Proceed as follows:

[0135] 1) Clamp a workpiece to be measured, and measure its circumference manually;

[0136] 2) Estimate a D in advance 0 estimated value;

[0137] 3) Utilize the control system to automatically measure and calculate the girth value according to the method of the present invention, the result is compared with the girth value of 1), and the subtraction obtains the girth error value;

[0138] 4) If the circumference error value is outside the allowable range, adjust D 0 Estimated value, repeat 3) until the error is smaller than the expected value.

[0139] The measurement process is divided into three step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com