Rotary battery pack thermal management system based on air-cooling uniform temperature control

A thermal management system and battery pack technology, applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of reducing the service life of battery packs, battery temperature differences, ignoring battery uniformity research, etc., to achieve temperature uniformity The effect of improving performance and battery uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

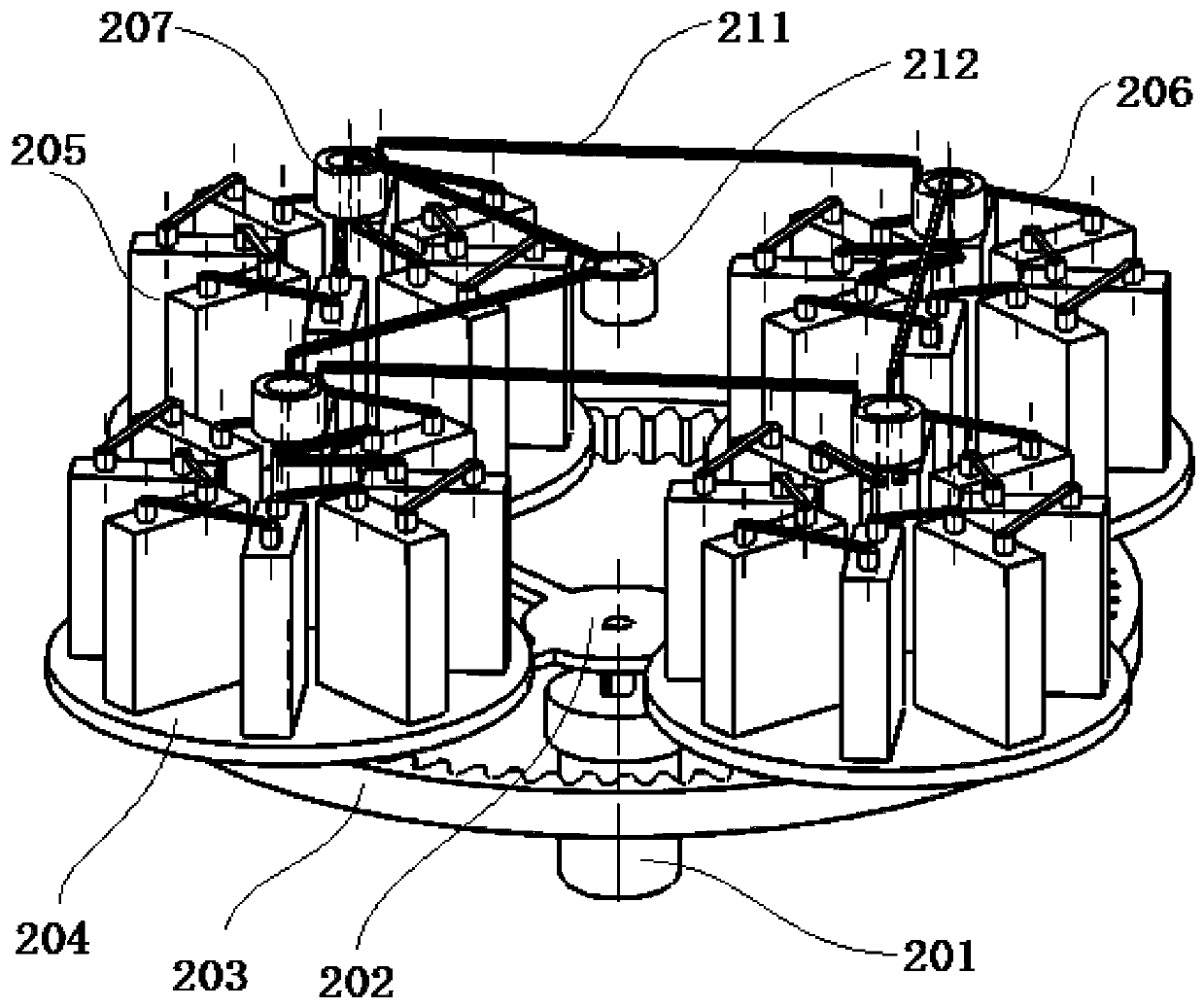

[0027] Below in conjunction with accompanying drawing, the present invention will be further described.

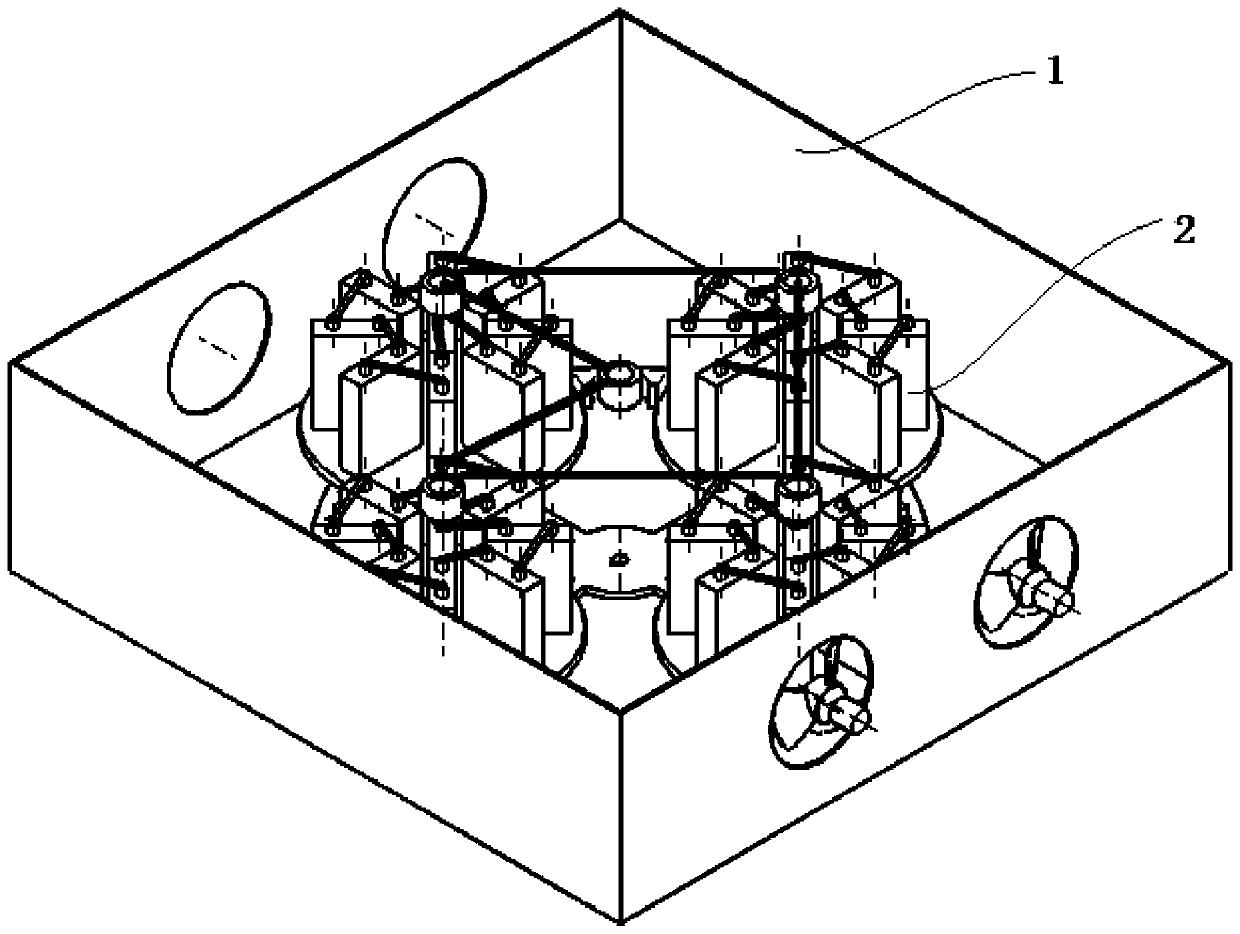

[0028] Such as figure 1 In the schematic diagram of the overall structure shown, a rotating battery pack heat management system based on air cooling and uniform temperature control includes two parts: a box body 1 and a battery pack rotating module 2 placed in the box body 1, and the box body 1 is used to automatically The heat dissipation structure of the belt, the turnover and rotation movement inside the battery pack rotating module 2 perform thermal management on the batteries placed therein.

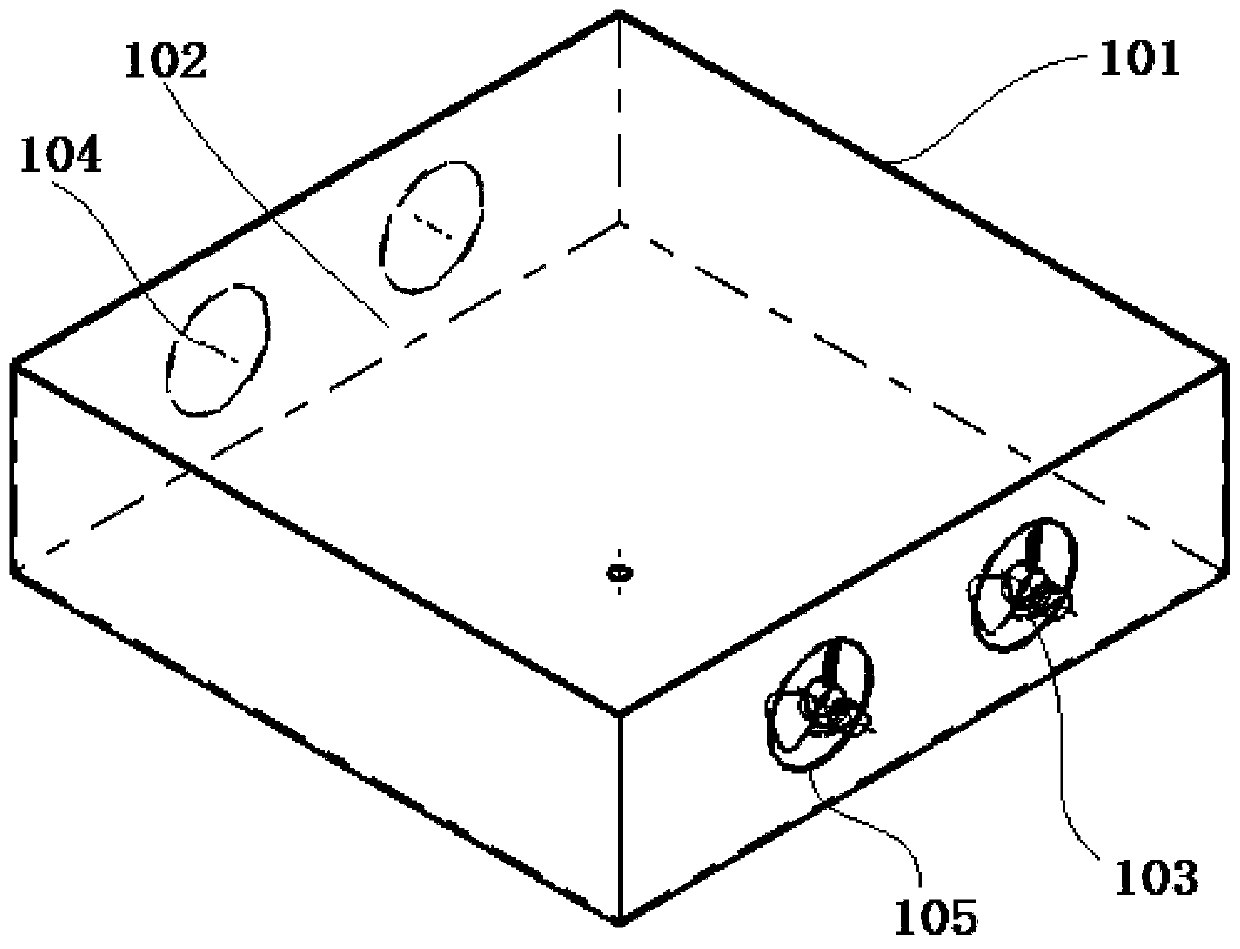

[0029] refer to figure 2 The schematic diagram of the three-dimensional structure of the box body 1, the box body 1 is composed of a box body shell 102, a box body cover 101 and a fan 103, there are several groups of air inlets 105 on the box body shell 102, and the fans 103 are installed in the air inlets 105, the box body There are several groups of air outlets 104 on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com