Internal circulation oil-filled submersible motor with double-layer shell

A submersible motor, double-layer shell technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high output power density of the motor, heat can not be dissipated in time, shorten the life of the motor, etc., to improve the heat dissipation capacity, Facilitate lightweight design and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

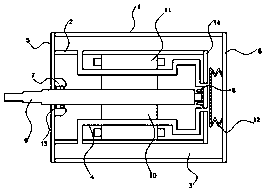

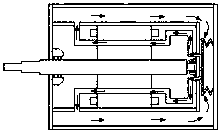

[0023] combine Figure 1-Figure 3 As shown, this embodiment discloses a double-layer shell inner circulation oil-filled motor, which includes a fully enclosed outer shell 1, an inner shell 2 coaxially fixed in the outer shell, and an inner cavity 3 with holes leading to the outer shell on the inner shell. , through the motor stator and rotor air gap, the end air gap and the heat dissipation module formed from the inner shell hole to the outer shell cavity, the front end cover 5, the rear end cover 6, the front thrust bearing 7, the rear thrust bearing 8, and the motor shaft 9. The stator 10 and the rotor 11; the front and rear ends of the motor housing 1 are respectively provided with a front end cover 5 and a rear end cover 6, the front end cover 5 is provided with a front thrust bearing 7, and the rear end cover 6 is provided with There is a rear thrust bearing 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com