Metal die-casting machine nozzle device that can spray evenly

A die-casting machine and nozzle technology, which is applied in the field of metal die-casting machines, can solve problems such as disassembly, affecting production capacity, and poor atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

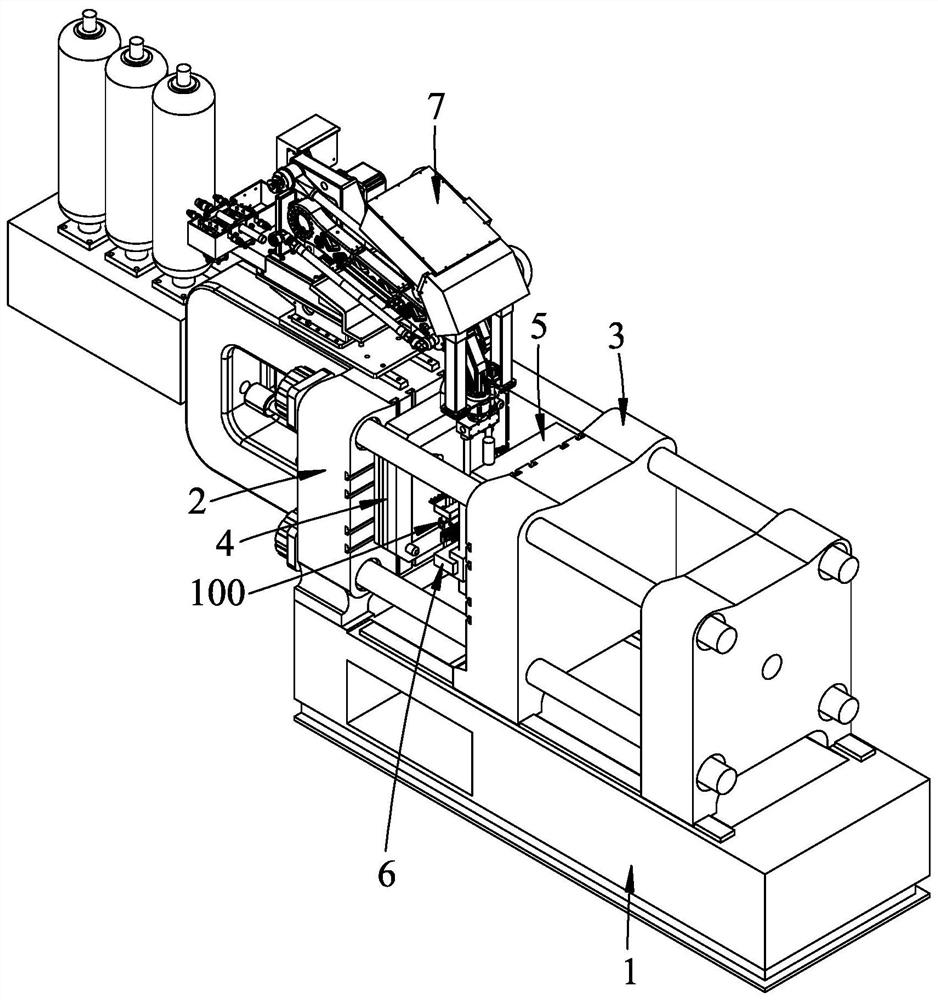

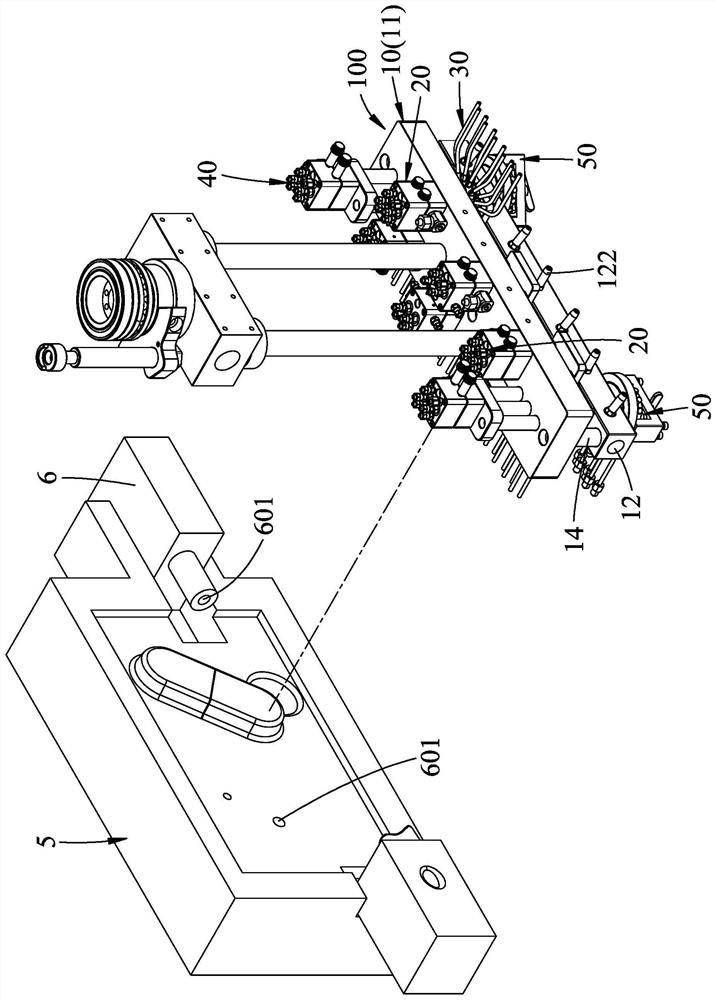

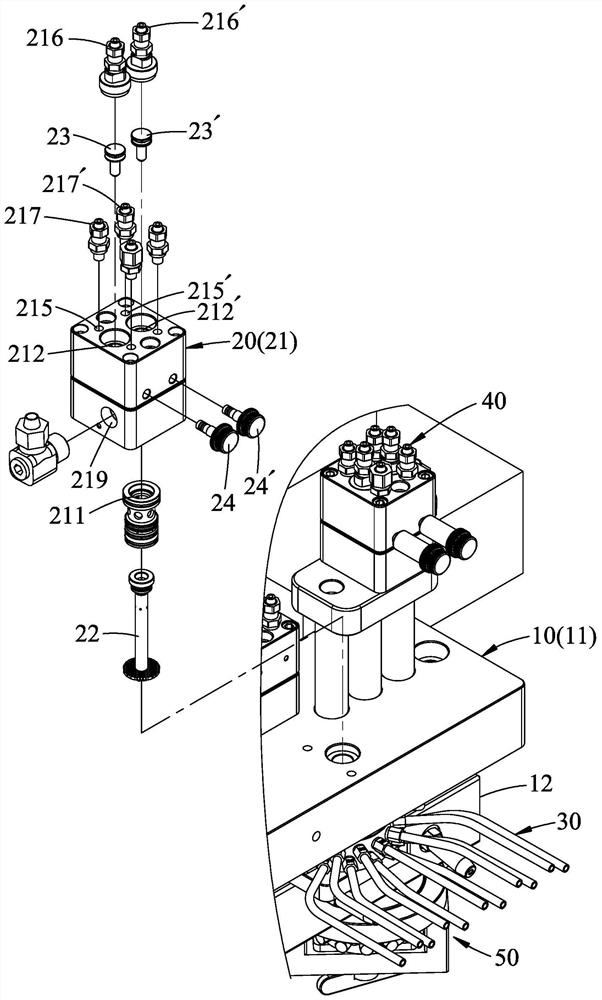

[0034] refer to figure 1 , figure 2 and image 3 , an embodiment of the nozzle device 100 of the metal die-casting machine that can spray uniformly in the present invention, the metal die-casting machine also includes a machine table 1, a fixed mold base 2 fixed on the machine table 1, a slidable and set on the machine table Machine 1 and a movable mold base 3 opposite to the fixed mold base 2, a female mold 4 installed on the fixed mold base 2, a male mold 5 installed on the movable mold base 3, a male mold connected to the male mold 5, and a cantilever unit 7 fixed on the top of the fixed mold base 2, the male mold 5 and the side module 6 each have at least one deep hole 601 shown in this embodiment. The spray head device 100 includes a base unit 10 , several main sprayers 20 , several main nozzle units 30 , several auxiliary sprayers 40 and sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com