Water pump impeller surface finish machining method

A technology of surface finishing and water pump impeller, which is applied in the direction of metal processing equipment, surface polishing machine tools, manufacturing tools, etc., can solve the problems of blade surface finishing uniformity differences, affect the working efficiency of water pumps, and reduce processing accuracy, etc., to improve The effect of uniformity, stable clamping, avoiding relative movement and relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

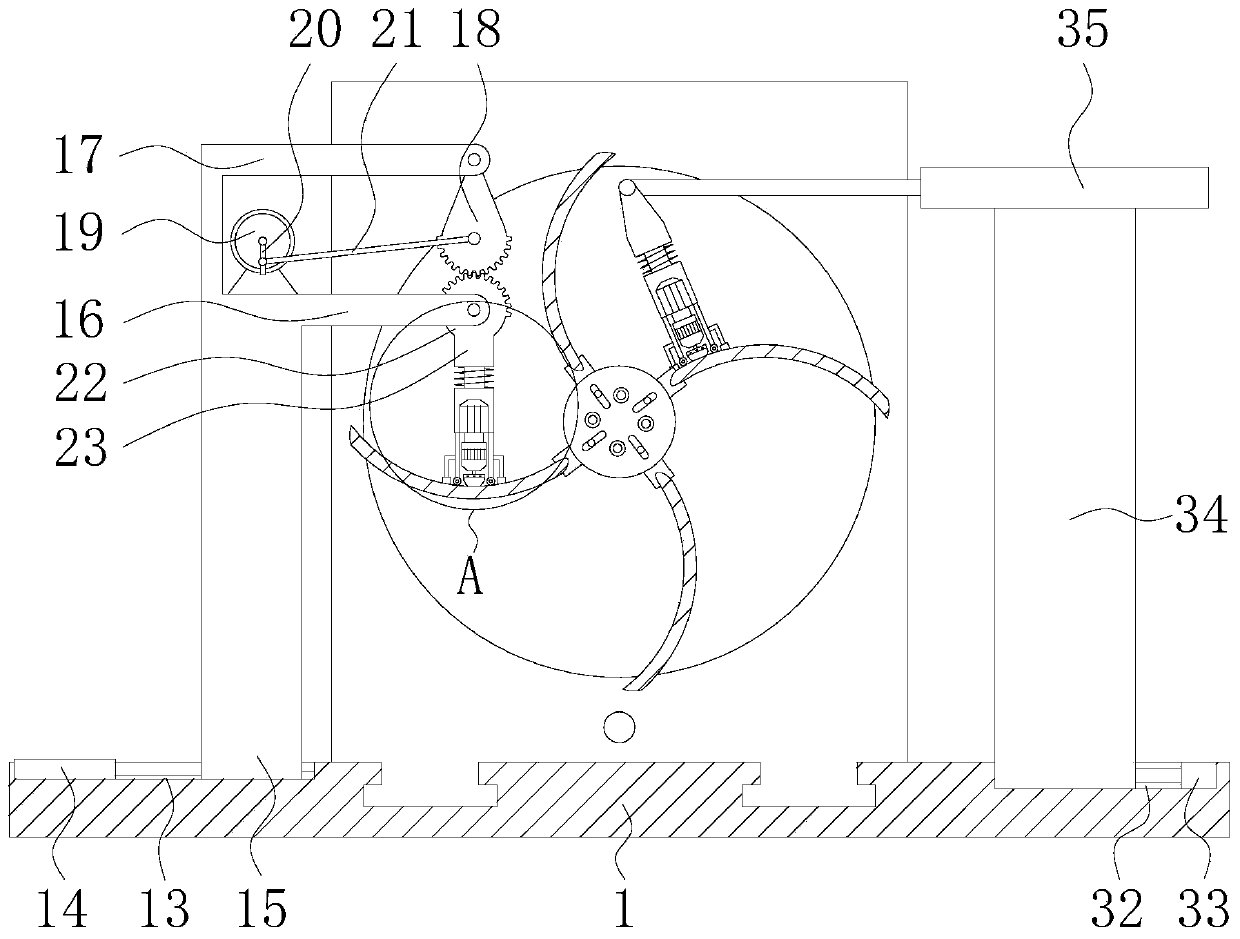

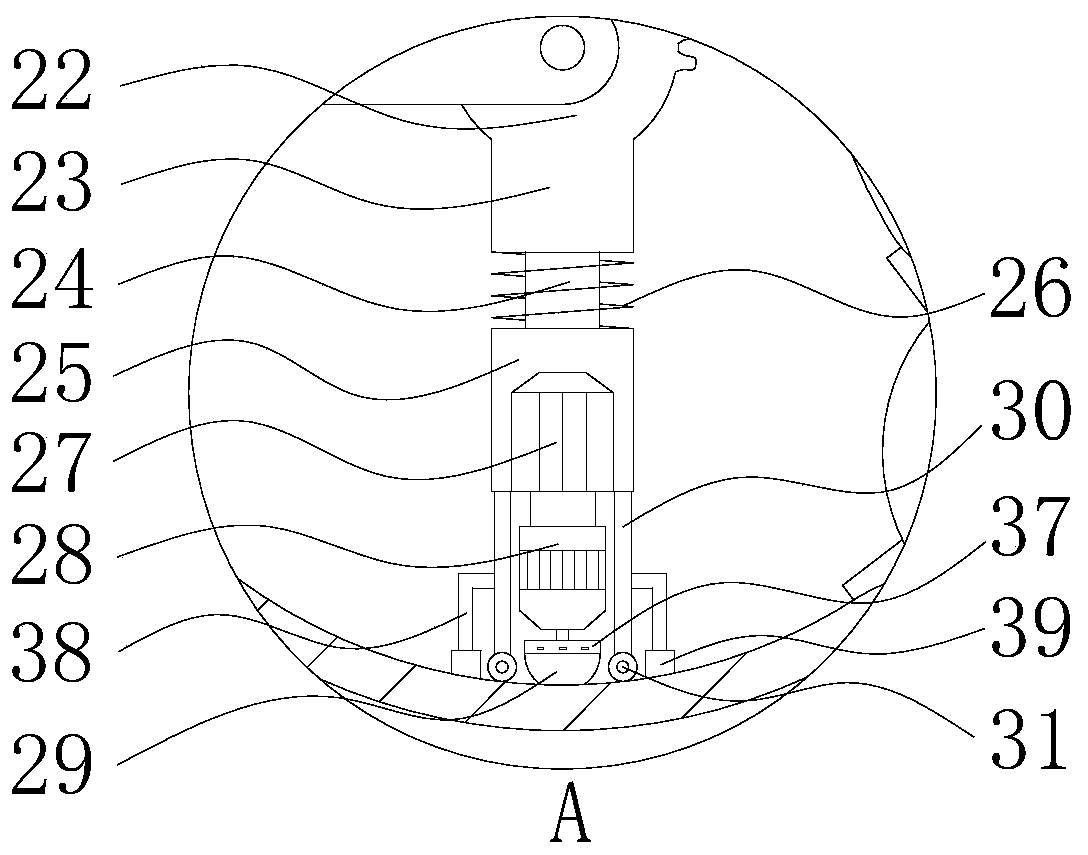

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

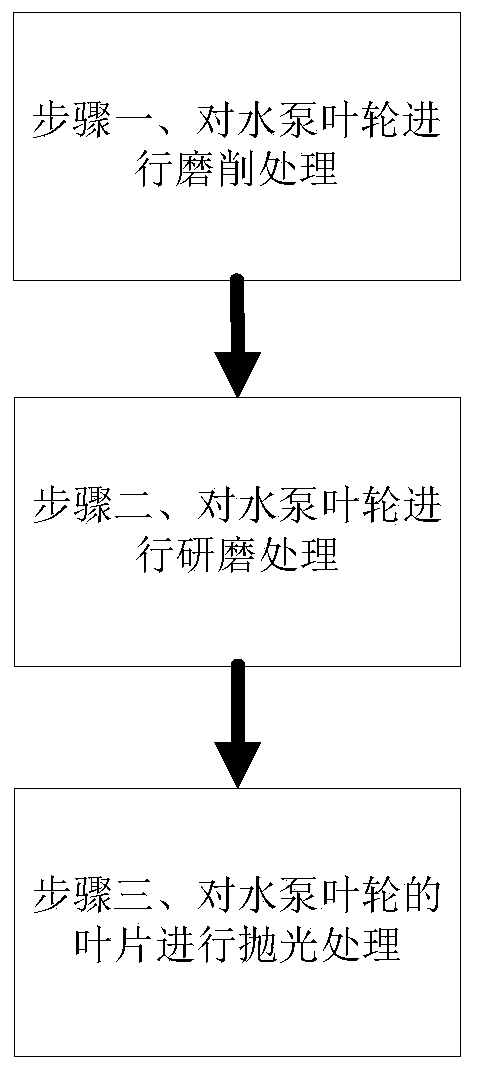

[0039] Such as figure 1 As shown, the present embodiment provides a water pump impeller surface finishing treatment method, comprising the following steps:

[0040] Step 1. Immerse the cast water pump impeller in the grinding fluid, and then place it on the machine tool to grind the front and rear cover circumferential surfaces of the water pump impeller.

[0041] Step 2: Grinding the impeller blades of the water pump after the grinding treatment.

[0042] Step 3, clamping the ground water pump impeller to the water pump impeller surface finishing treatment equipment, and polishing the blades of the water pump impeller.

[0043] In the above steps, the blades are polished by the water pump impeller surface finishing treatment equipment in step 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com