Device applicable to accessory blank cutting

A technology of equipment and accessories, which is applied in the field of equipment for blank cutting of accessories, can solve the problems of consumption, expensive industrial knives, multiple knives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

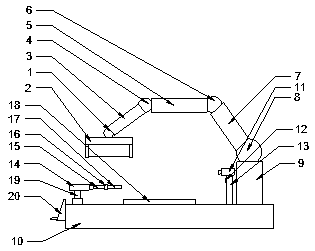

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

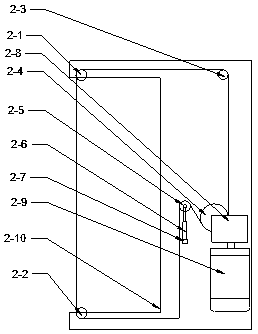

[0014] Such as Figure 1 to Figure 2 As shown, this equipment is suitable for the blank cutting of accessories, including the first-level joint shaft 1, the cutter 2, the first-level cutting arm 3, the second-level joint shaft 4, the second-level cutting arm 5, the third-level joint shaft 6, and the third-level cutting Arm 7, four-stage joint axis 8, four-stage base arm 9, equipment base 10, camera 11, 3D laser modeler 12, observer pillar 13, accessory orientation adjustment arm 14, hydraulic telescopic arm 15, gripper joint 16. Gripper 17, cutting table 18, grabbing arm hydraulic prop 19 and console 20, the surface of the equipment base 10 has a hole to install the grabbing arm hydraulic prop 19, and one end of the grabbing arm hydraulic prop 19 is equipped with an accessory azimuth adjustment arm 14. A hydraulic telescopic arm 15 is installed on one side of the acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com