Establishment method and application of prediction model of scutellaria baicalensis extract production process

A technology of Scutellaria baicalensis extract and production process, which is applied in the field of prediction model establishment, can solve problems such as the inability to guarantee the consistency of product quality between batches, and achieve the effect of ensuring consistency between batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

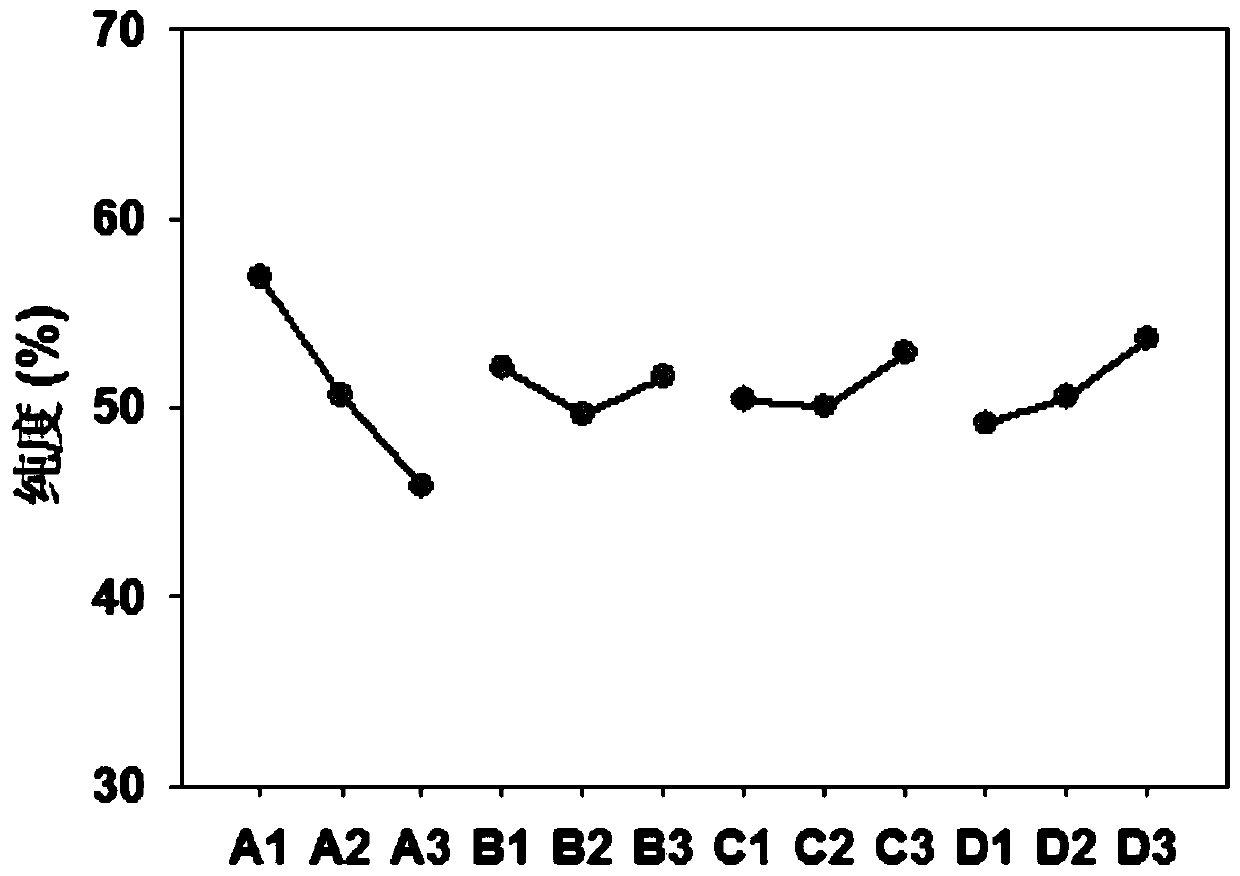

[0048] Example 1 Screening of production process parameters of Scutellaria baicalensis Georgi extract

[0049] (1) Preparation and content determination method of Scutellaria baicalensis Georgi extract

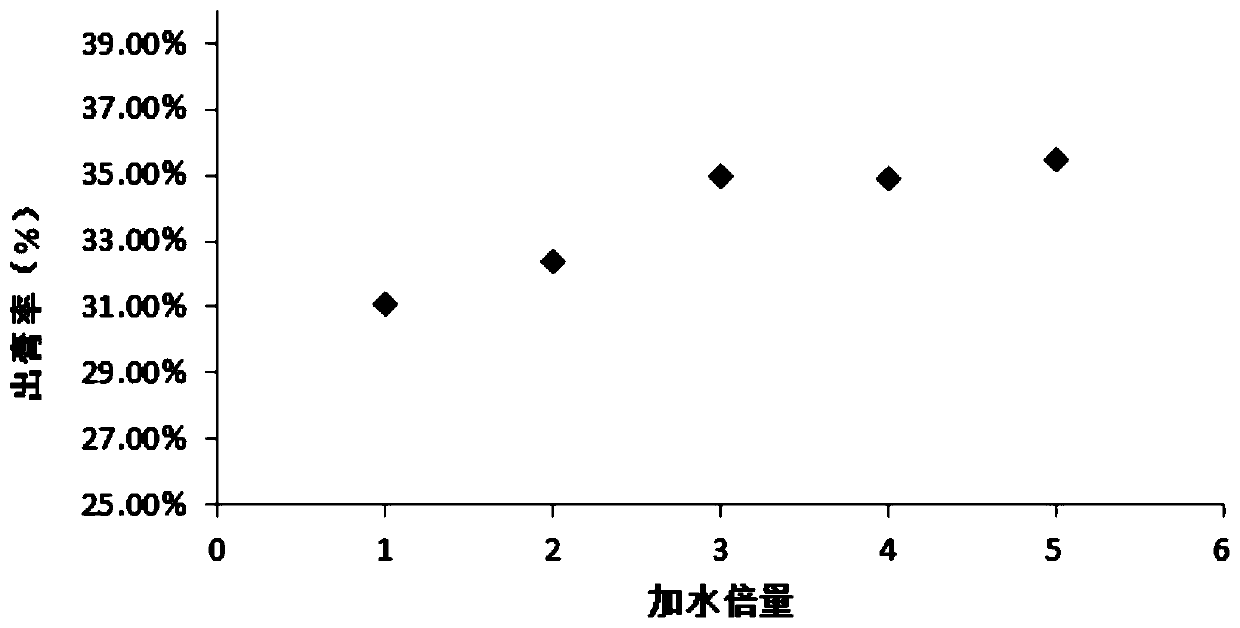

[0050] The preparation process of Scutellaria baicalensis Georgi extract is carried out according to the preparation method of Scutellaria baicalensis Georgi extract described in the 2015 edition of "Chinese Pharmacopoeia": Take Scutellaria baicalensis Georgi, add water to decoct, combine the decoction, concentrate to an appropriate amount, adjust the pH value to 1.0-2.0 with hydrochloric acid, Incubate at 80℃, let stand, filter, add appropriate amount of water to the precipitate and stir evenly, adjust the pH to 7.0 with 40% sodium hydroxide solution, add the same amount of ethanol, stir to dissolve, filter, and adjust the pH to the filtrate with hydrochloric acid Incubate at 1.0-2.0 at 60°C, stand still, filter, and wash the precipitate with proper amount of water and ethanol of ...

Embodiment 2

[0080] This embodiment provides a method for establishing a prediction model for the production process of Scutellaria baicalensis Georgi extract, which includes the following steps:

[0081] (1) Select the selected raw material attribute parameters of Scutellaria baicalensis Georgi, the selected production process parameters of Scutellaria baicalensis Georgi extract and the quality attribute parameters of the selected Scutellaria baicalensis Georgi extract;

[0082] Screened raw material attribute parameters of Scutellaria baicalensis Georgi

[0083] The key material properties of the selection of Scutellaria baicalensis decoction pieces include the content of baicalin, wogonin, baicalein, wogonin and melaleuca in the decoction pieces of Scutellaria baicalensis. In order to simulate the changes in the key material attribute parameters of raw materials of Scutellaria baicalensis Georgi, 10 batches of decoction pieces of Scutellaria baicalensis Georgi were purchased, which were identi...

Embodiment 3

[0115] This embodiment provides a method for predictively controlling the mixed batch ratio of raw materials by using the prediction model of the production process of the Scutellaria baicalensis extract described in Embodiment 2, which includes the following steps:

[0116] First, given a batch of raw materials of Scutellaria baicalensis pieces (No. GS1), it is assumed that the production method of fixed process parameters is used to prepare Scutellaria baicalensis extracts. The fixed key process parameters are that the density of the concentrated solution is equivalent to 0.6g slices / mL, and the amount of precipitate added to water is 1.2 It is twice the quality of decoction pieces and the holding time at 60℃ is 90min.

[0117] (1) The control target of each quality attribute parameter of the selected Scutellaria baicalensis extract is set to be no less than 10% of the cream extraction rate, no less than 85.0% of the baicalin purity, and no less than 75% of the transfer rate. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

| Column inner diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com