Spark plug

A technology of spark plugs and ignition coils, applied in the field of spark plugs, can solve the problems of limited size optimization of spark plug installation holes, etc., and achieve the effects of optimizing design space, reasonable structural design, and reducing layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

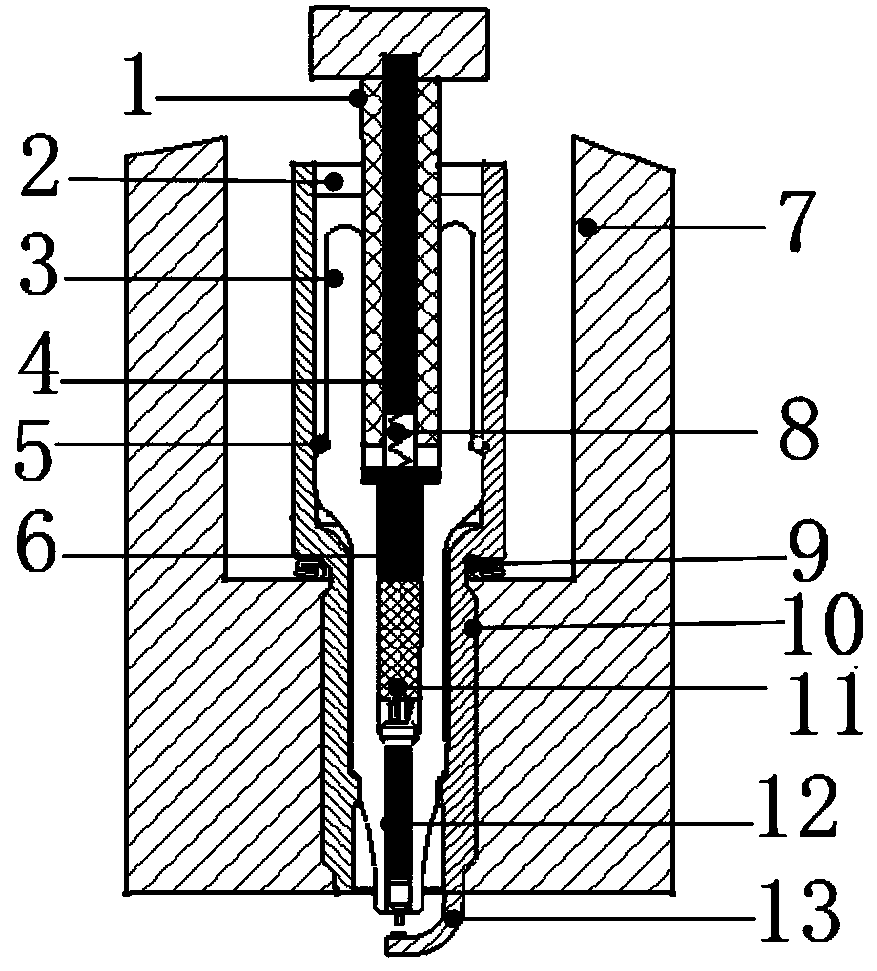

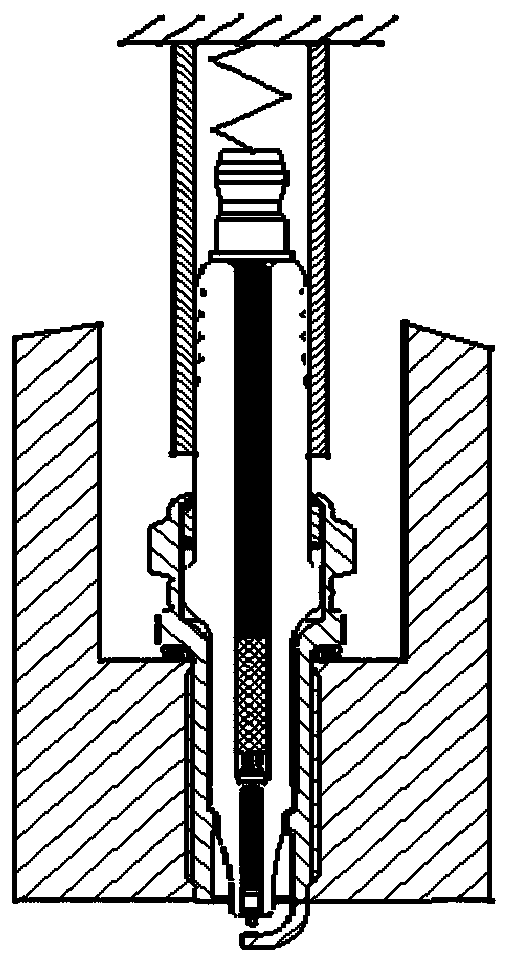

[0034] The ceramic body of the spark plug wraps the wiring screw, the resistance sealing material and the center electrode (the wiring screw, the resistance sealing material and the center electrode are closely connected in sequence), the upper part of the ceramic body is hollow designed to make the wiring screw sink, and the iron shell of the spark plug is designed from the lower welding side The electrode has a spark plug mounting thread on the outer side of the lower part, which is matched with the cylinder head through the mounting thread; the iron shell of the spark plug extends upwards to the ceramic body, and the upper iron shell of the ceramic body is designed as a circle, with an inverted hexagonal or flower shape inside, and the ceramic body passes through The inner gasket is fixed and sealed twice. Cooperate with the ignition coil, the ignition coil sheath is inserted into the center of the ceramic body of the spark plug, and the high-voltage energy is transmitted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com