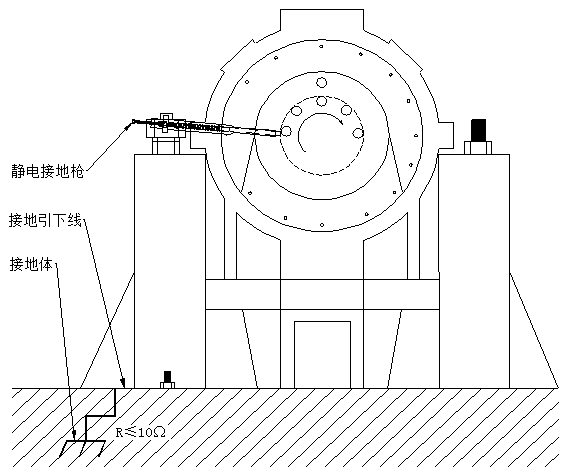

Grounding gun installed on rotating shaft

A grounding gun and shaft technology, applied in the field of grounding guns, can solve the problems of production reduction and load reduction, complex installation, high safety risks in online maintenance and replacement, and achieve the effect of improving product life and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

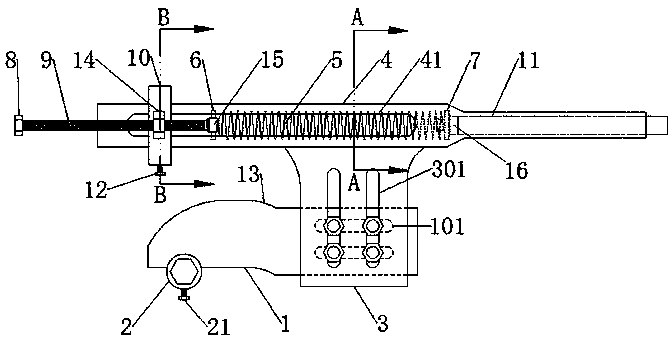

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

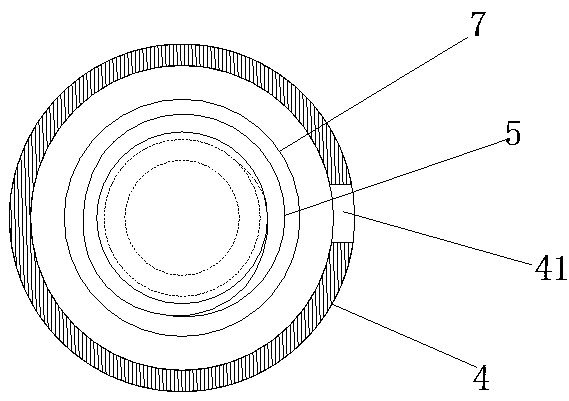

[0039] like Figure 1-6 As shown, a grounding gun installed on the rotating shaft, the grounding gun is connected to the steering support on the rotating shaft, conducts electricity through the graphite rod 11, and transmits the induced electricity to the steel pipe of the grounding gun through the second spring seat 7 4. Then it is transmitted to the second support plate 3 through the steel pipe 4 and then to the first support plate 1, and then transmitted to the second bolt 21 on the large cover of the unit through the fastening nut 2 on the first support plate 1, and then passed through the second The bolt 21 is transmitted to the compressor body, and finally relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com