A kind of optical fiber terminal and its production method

A connection terminal and optical fiber technology, which is applied in the field of automatic production equipment for optical fiber connection terminals, can solve the problems of unguaranteed product qualification rate, and achieve the effects of simple and efficient structure, small physical damage, and improved assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

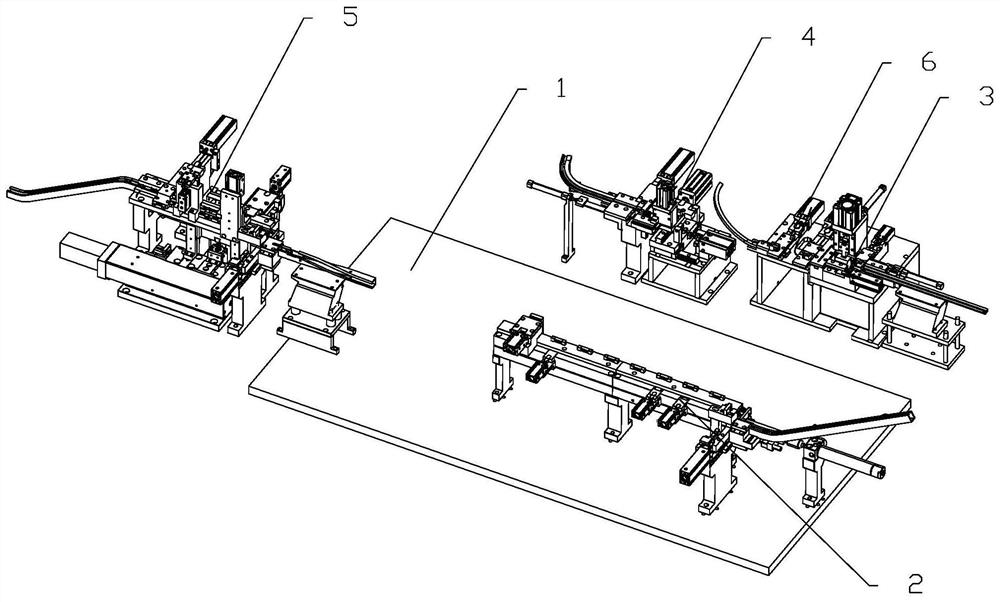

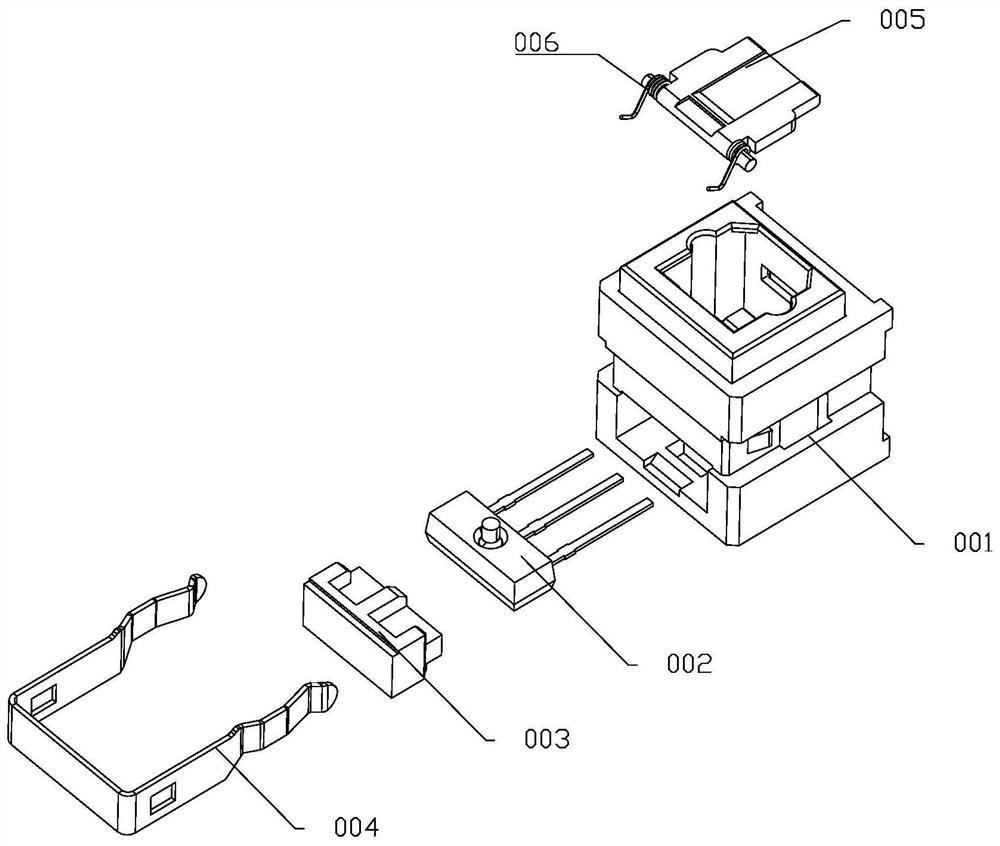

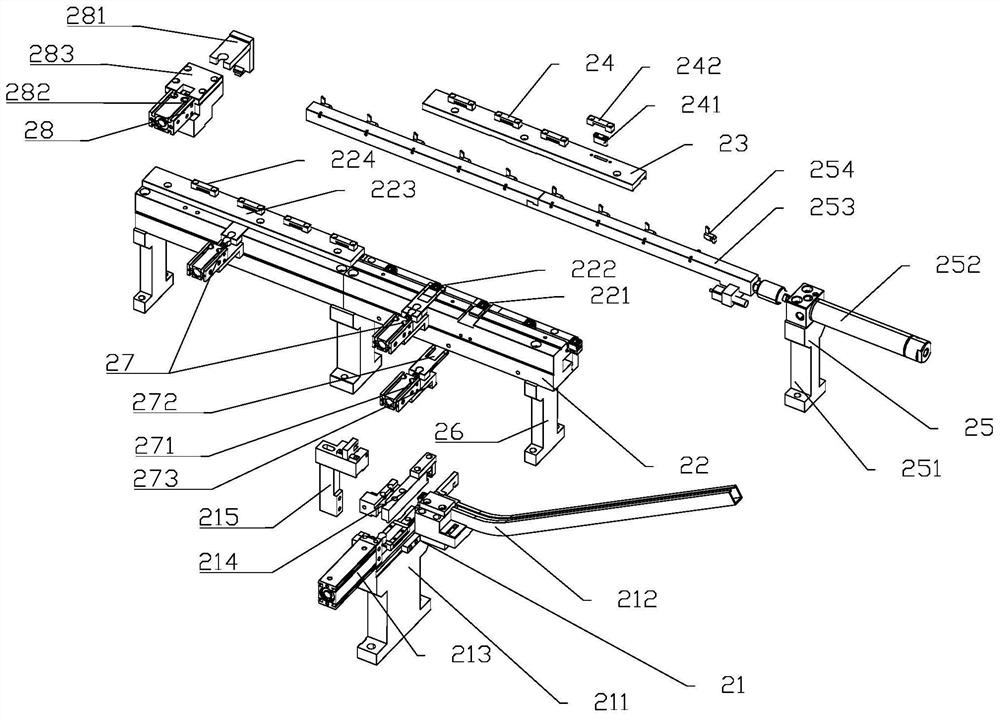

[0042] Such as figure 1 As shown, an automatic production equipment for optical fiber terminals includes a frame 1 and a positioning and feeding device 2 installed on the frame 1, an optical fiber core assembly device 3, a fastener assembly device 4, a detection and sorting device 5 and glue Block assembling device 6; optical fiber core assembling device 3 and fastener assembling device 4 are installed on the side of positioning feeding device 2, optical fiber core assembling device 3 and fastener assembling device 4 are connected; detection sorting device 5 and positioning The feeding device 2 is connected; the positioning feeding device 2 is used to realize the feeding and feeding of the terminal housing, the optical fiber core assembly device 3 is used to cut and assemble the optical fiber core; the fastener assembly device 4 is used for Assemble the fasteners; the detection and sorting device 5 is used to perform performance detection on the assembled optical fiber termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com