Anti-toppling tool for installation of ship rudder blades

A technology of anti-dumping and rudder blades, which is applied in the direction of ship parts, metal processing, manufacturing tools, etc., can solve the problems of restricting the scope of use, reducing the use of personnel, wasting the value of fixed assets, etc., to improve the anti-dumping ability and improve safety performance, and the effect of improving intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

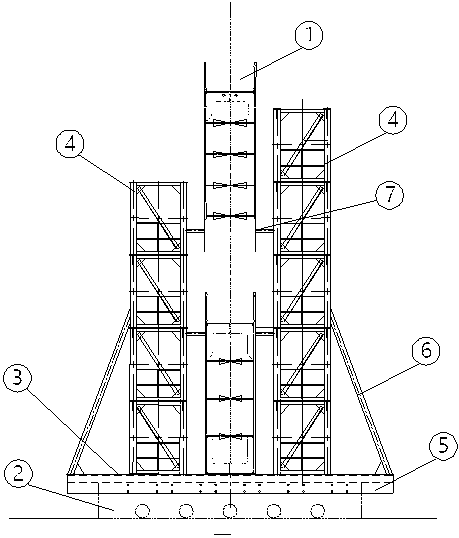

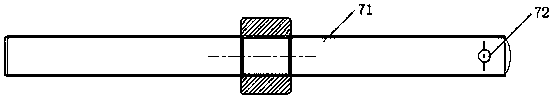

[0027] The anti-dumping frock installed on the rudder blade of the ship in this embodiment, its construction target is a large rudder blade 1, such as figure 1 As shown, it includes a combined modular vehicle 2, which is used for the transportation and adjustment of the installation of the rudder blade 1; The main platform of concentrated load; the rudder blade anti-dumping tooling platform 3 is fixedly connected to the upper surface of the combined modular vehicle 2 through the platform connecting plate 5 .

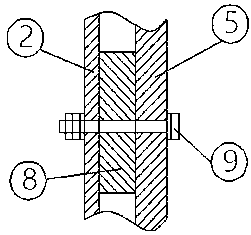

[0028] The platform connecting plate 5 is welded with the rudder blade anti-dumping tooling platform 3, and the rudder blade anti-dumping tooling is connected with the combined modular vehicle 2 with connecting bolts 9 to form a whole. This is a very important link in the whole design. It is connected with tooling to reduce the possibility of rudder blade overturning and improve intrinsic safety.

[0029] As an example, a more specific implementation is that a connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com