Multistation rotary disc device of female header plastic shell

A plastic shell, multi-station technology, applied in assembly machines, metal processing, manufacturing tools, etc., can solve the problems of low production efficiency, achieve high-efficiency actions, improve reliability, and avoid short-circuit failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

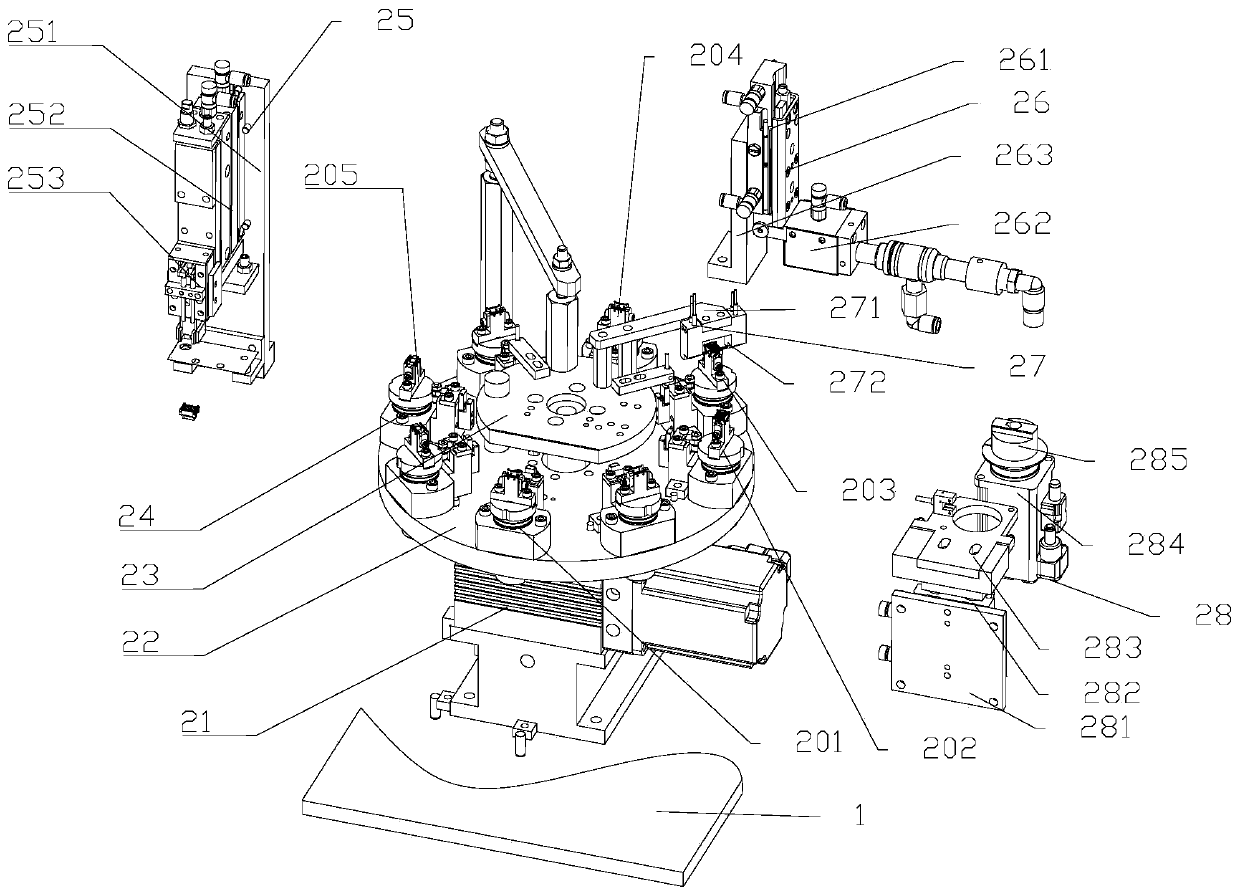

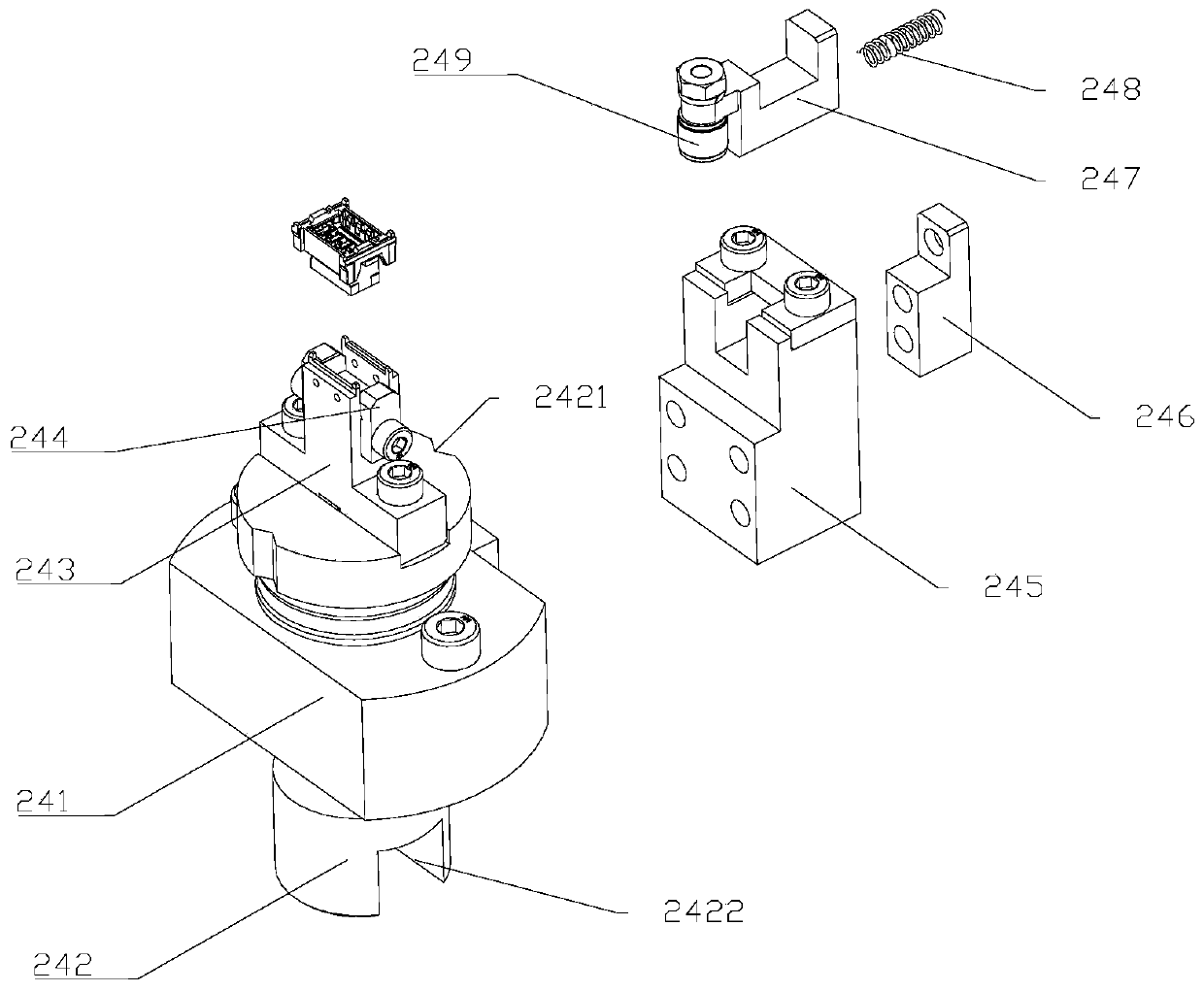

[0020] Such as figure 1 As shown, a multi-station turntable device for a female row plastic shell includes a frame 1 and a divider 21 installed on the frame 1, a turntable 22, a mounting table 23, a carrier 24, a pre-pressing mechanism 25, and a dust removal mechanism 26. The limit detection mechanism 27 and the rotation mechanism 28; the divider 21 is fixedly arranged on the frame 1, the turntable 22 is connected with the rotating end of the divider 21, and the mounting table 23 is fixed with the fixed part on the divider 21; The tool 24 is evenly distributed on a week of the turntable 22, and there are eight groups. The turntable 22 includes a loading station 201, a dust removal station 202, a detection station 203, an assembly station 204, and an unloading station 205; It is used to set the female row plastic shell; the pre-pressing mechanism 25 is fixedly arranged on the installation platform 23, corresponding to the feeding station 201, and is used to compress the female ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap