An assembly method for improving the metering accuracy of a membrane gas meter

A membrane gas meter and measurement accuracy technology, which is applied in the direction of volume measurement, measuring devices, assembly machines, etc., can solve problems such as unstable operation, inability to rotate with the crank, poor continuity of crank rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

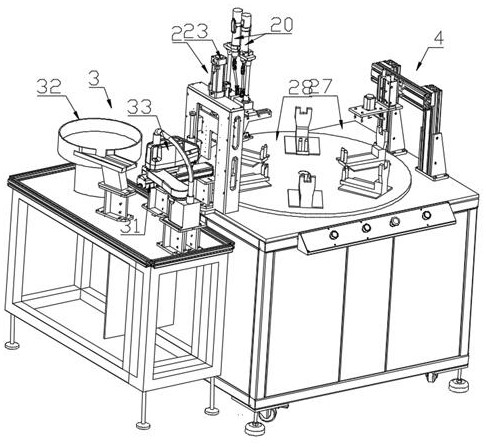

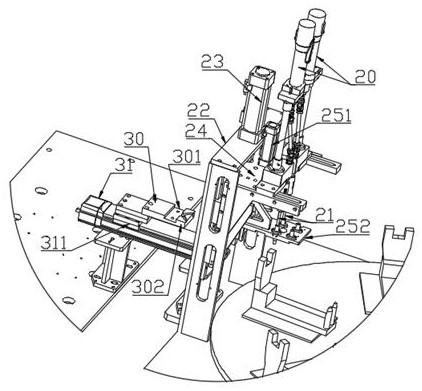

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] An assembly method for improving the metering accuracy of a membrane gas meter, comprising the following steps:

[0035] a. Double rocker arm positioning:

[0036] Keep the two rocker arms overlapping vertically and form a symmetrical X-shaped cross in the direction of top view;

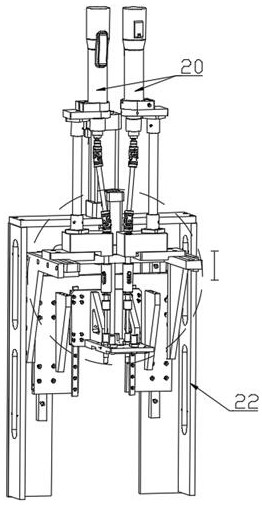

[0037] b. Double rocker arm pressing:

[0038] Press-fit the sleeve 101 for connecting the vertical shaft on the double rocker arm in step a to the knurled section at the top of the double vertical shaft 11;

[0039] Also include step c done before step b:

[0040] c. Double vertical shaft 11 rotation positioning:

[0041] After the double vertical shafts 11 are rotated to synchronously drive the flaps, diaphragms and diaphragms to move, the diaphragms in each metering box 12 are positioned at the center line of the metering box 12 in the thickness direction to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com