Scraped car disassembling system

A technology for scrapped automobiles and automobiles, which is applied in the direction of scrapped and recycled vehicles, motor vehicles, and solid waste removal, etc., can solve the problem of increasing the difficulty of dismantling scrapped automobiles by operators, the difficulty of dismantling scrapped automobiles, and the inconvenience of dismantling scrapped automobiles. and other problems, to achieve the effect of light weight, small footprint, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

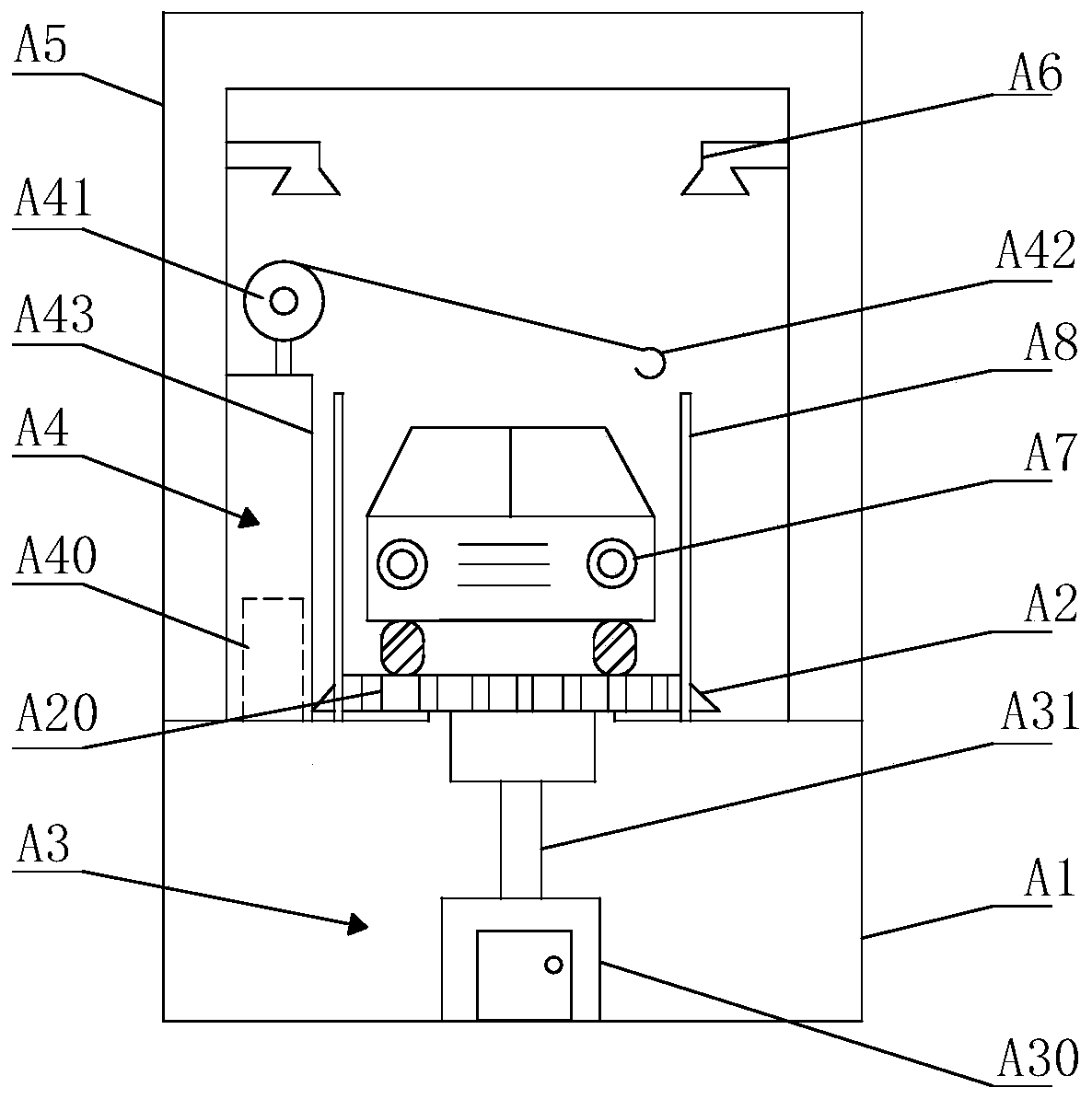

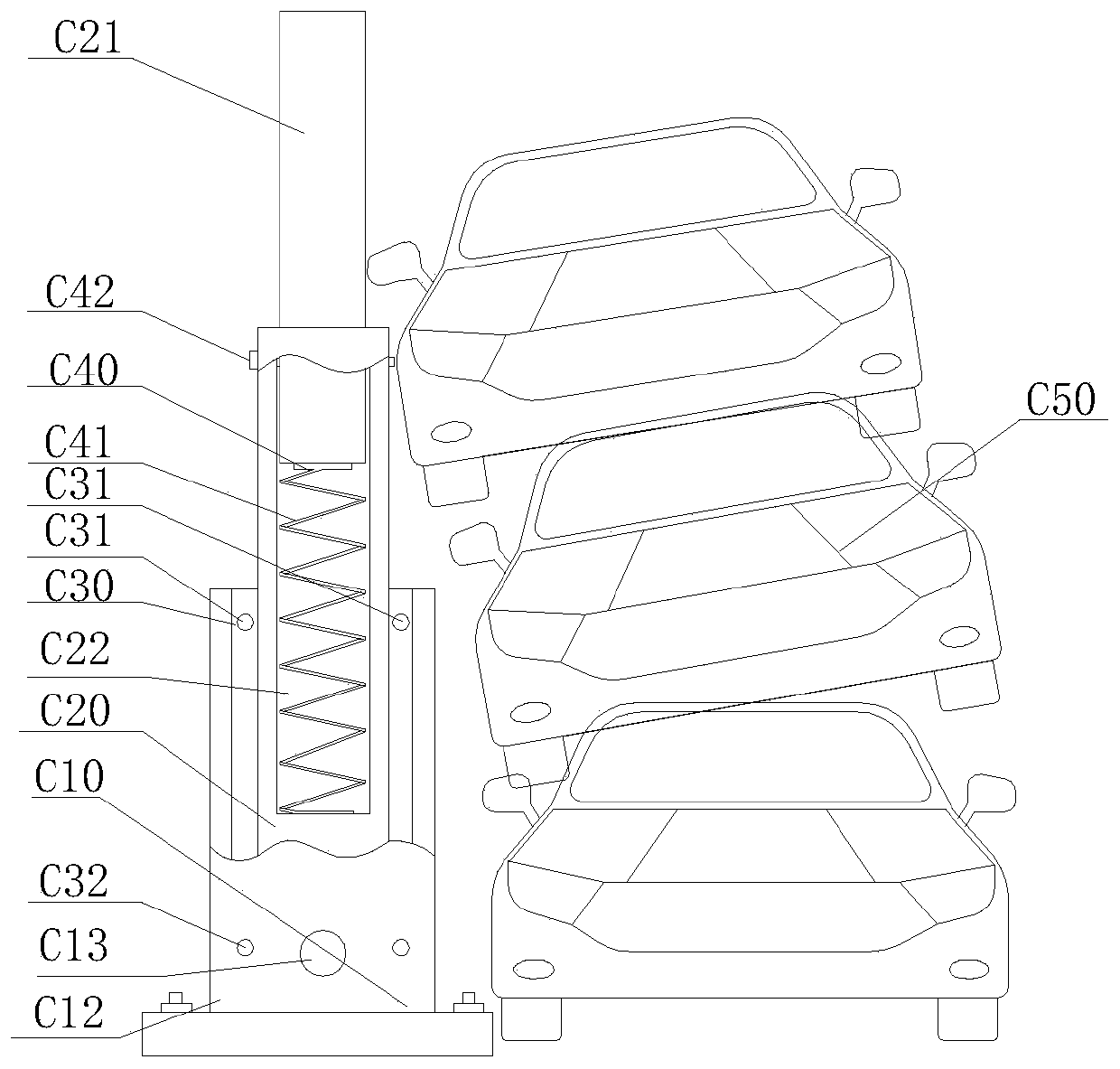

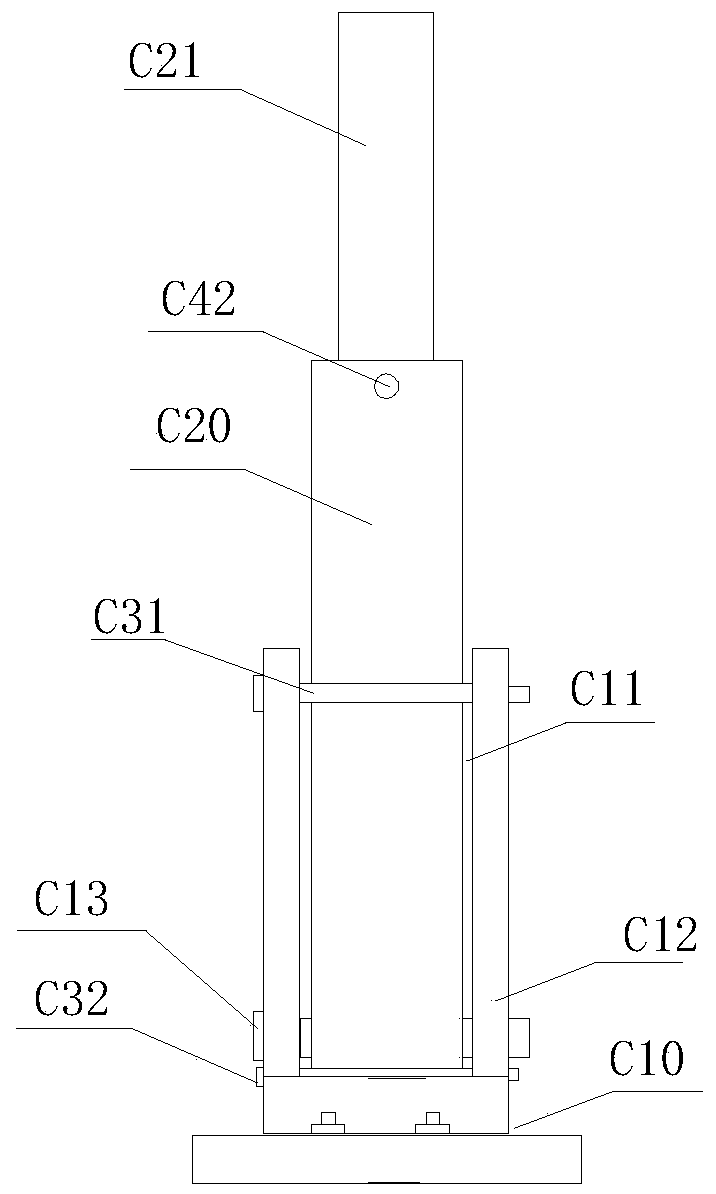

[0085] The invention relates to a system for dismantling scrapped automobiles. The system sequentially includes a vehicle power energy recovery device, a scrapped automobile parking device, a scrapped automobile processing platform, and a parts processing device according to the sequence of processing. The following describes the system operation steps respectively.

[0086] 1. Vehicle power energy recovery device, including waste oil recovery device and vehicle natural gas cylinder removal device, as follows:

[0087] 1.1 Waste oil recovery device

[0088] Such as Figure 10-11 As shown, the waste oil recovery device includes a lift truck F10 and an oil extraction tank F20 arranged on the lift truck F10. An oil extraction mechanism F40 is arranged in the oil extraction tank F20. Outside; the lift car F10 is also provided with a filter box F30 connected with the fuel tank F20; the filter box F30 is provided with an oil discharge pipe F32; the fuel tank F20 is fixed on the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com