Mechanical automatic feeding mechanism

A feeding mechanism and mechanical technology, applied in the direction of solid materials, packaging, packaging items, etc., can solve problems such as reducing safety, reducing production efficiency, and increasing costs, reducing labor waste, improving safety, and increasing production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

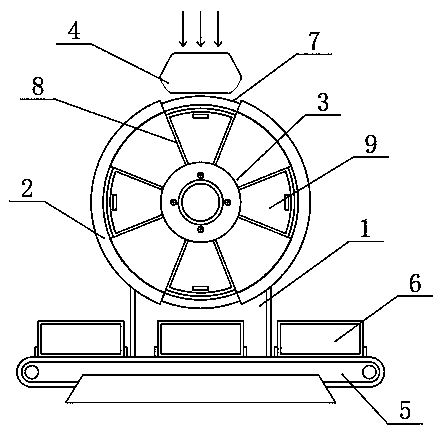

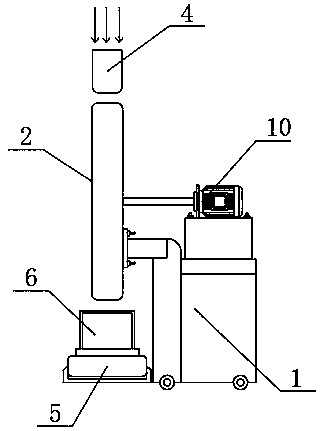

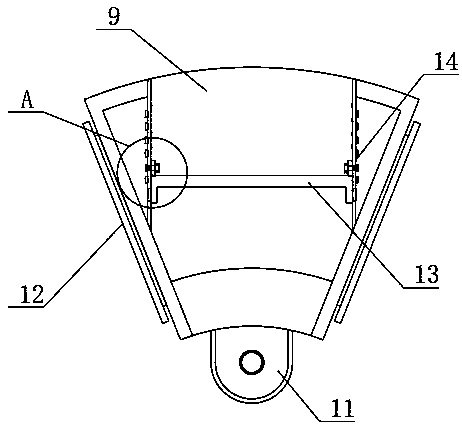

[0020] see Figure 1-5 , the present invention provides the following technical solutions: a mechanical automatic feeding mechanism, including an outer shell 2, an inlet shell 4 above the outer shell 2, and a conveyor belt assembly 5 below the outer shell 2. Material box 6, one side of outer casing 2 is provided with fixed seat 1, and fixed seat 1 and outer casing 2 are fixedly connected by fastening screw, and the upper surface of fixed seat 1 is fixedly connected with motor 10 by bolt, and in the present embodiment, motor 10 is a motor of the type SST86D1605 produced by Dongguan Morse Automation Technology Co., Ltd., the inside of the outer casing 2 is provided with a roulette body 3, and the inside of the roulette body 3 is provided with a card slot 8, and the output end of the motor 10 is connected to the roulette The body 3 is connected by transmission, and the inside of the card slot 8 is provided with a connecting box 9, and both sides of the connecting box 9 are integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com