Positive pressure air seal machine and rice hull conveying device

A technology of conveying device and air lock, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., which can solve the problems of low unloading efficiency, loss of manpower and financial resources, and difficulty in unloading, so as to ensure the smoothness of rotation, Reduce energy waste and solve the effect of cutting difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

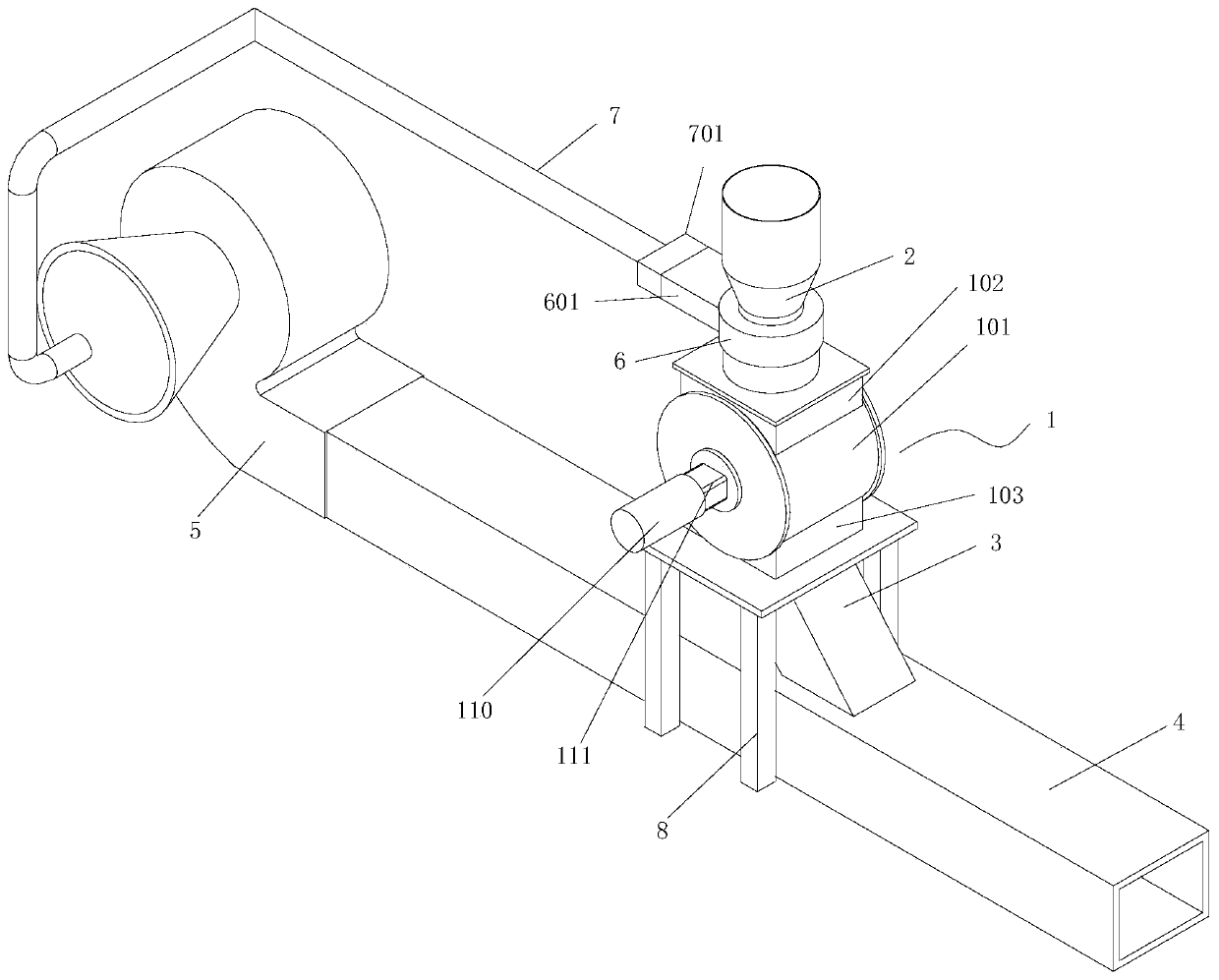

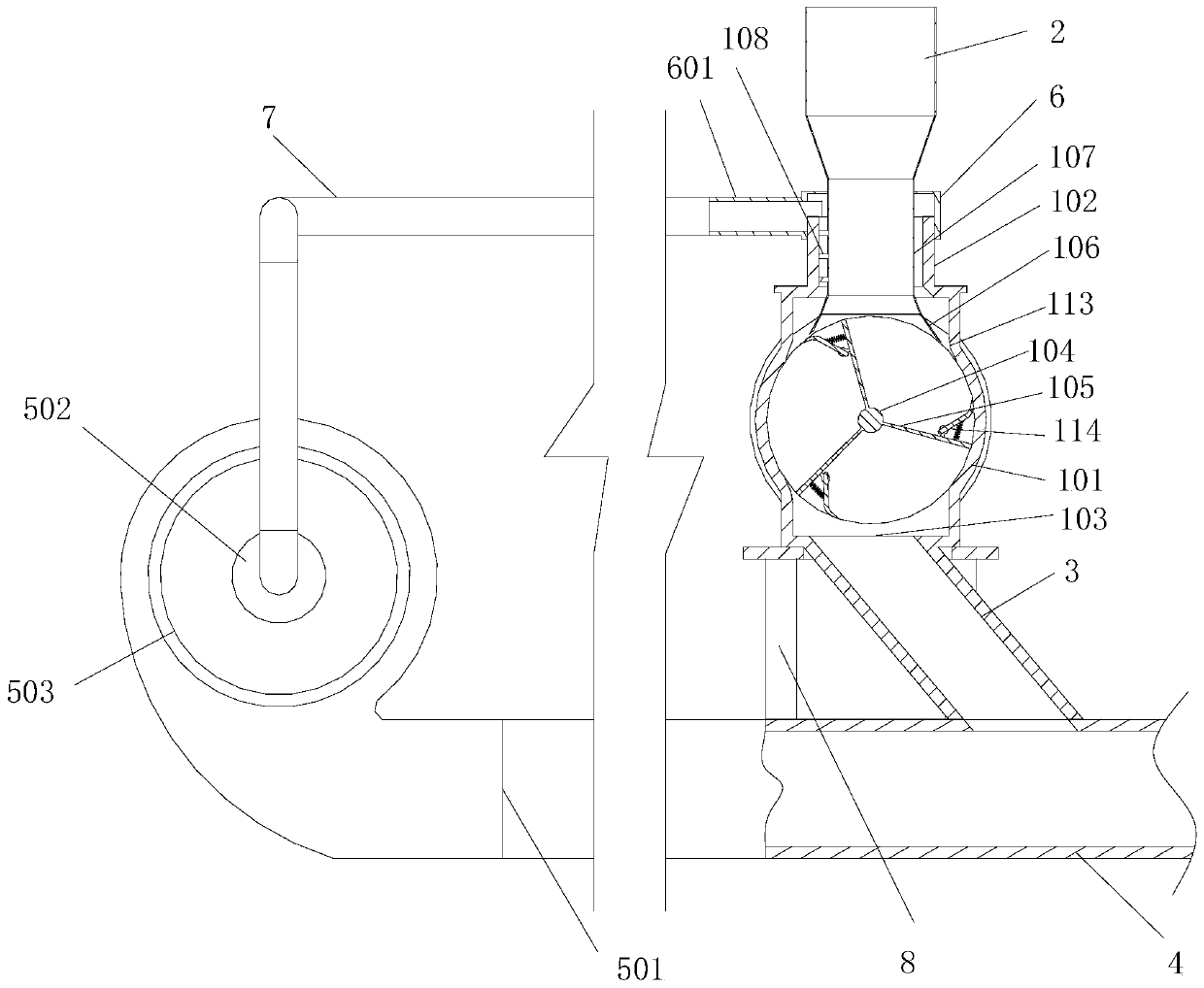

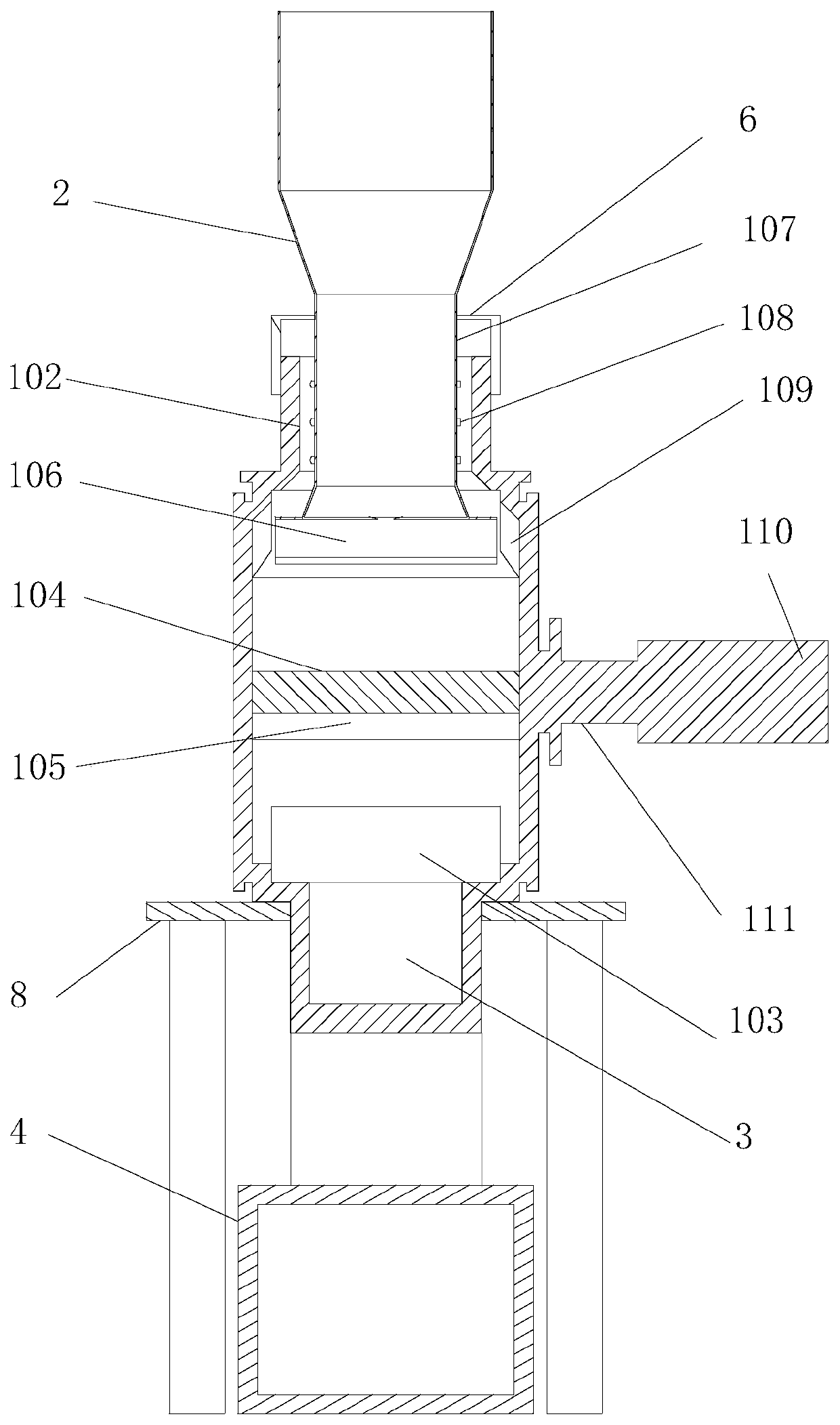

[0024] Such as Figure 1-6 As shown, the present invention includes an air lock main body 1, the air lock main body 1 includes a housing 101, an inlet port 102 and an outlet port 103 arranged at both ends of the housing 101 and a fan blade 105 arranged in the housing 101, The fan blade 105 is provided with an elastic seal to reduce air leakage, and the inlet end 102 is provided with a wind extinguisher, and the outer wall of the air extinguisher and the inner wall of the inlet end 102 form a wind elimination channel, and the outlet end 103 passes through the fan. The return air from the blade 105 is guided into the air elimination channel by the air elimination element to be eliminated.

[0025] In the present invention, an elastic seal is provided on the fan blade 105 to reduce the gap between the fan blade 105 and the inner annular inner wall of the casing 101, and at the same time ensure the smoothness of the rotation of the fan blade 105, and the elastic seal greatly reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap