Water-based directly-coated fabric sofa leather

A sofa leather, water-based technology, applied in textiles and papermaking, etc., can solve the problems of poor hand feeling, high cost and cumbersome production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

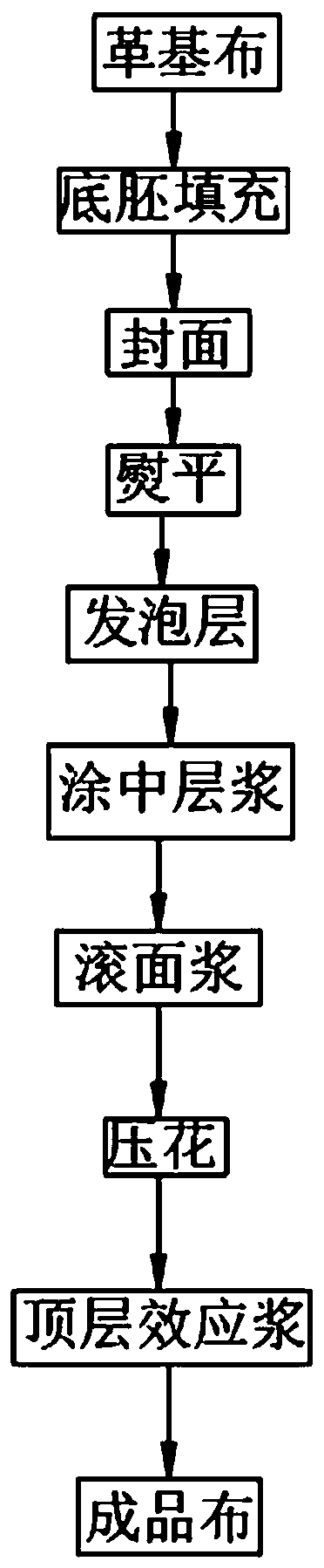

[0035] see figure 1 , the present invention provides the following technical solutions: a water-based direct-coating sofa leather, comprising a water-based direct-coating sofa leather production process, the water-based direct-coating sofa leather includes leather base cloth, bottom blank filling, cover, ironing, and foaming layer , Coating middle layer paste, rolling surface paste, embossing, top layer effect paste, finished cloth;

[0036] The production process of water-based direct coating sofa leather is as follows:

[0037] (1) Material selection: choose the leather base cloth as the base material cloth; use the soft leather base cloth to fill the cloth to make the cloth have the texture of genuine leather, add the polyurethane coating of the genuine leather, and truly achieve the genuine leather cloth that is environmentally friendly and not aging;

[0038] (2) Filling: Fill the bottom embryo, squeeze in 50% of soft small-molecule polyurethane, 2% of JFC penetrant, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com