Water-based letter scraping ink for silk screen printing and preparation method thereof

A technology of screen printing and scraping ink, which is applied in the field of water-based scraping ink for screen printing and its preparation, can solve the problems of not meeting the requirements of environmental protection and its own health, poor air quality at the production site, and high risk factors. Achieve the effect of thick ink layer, strong three-dimensional effect and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

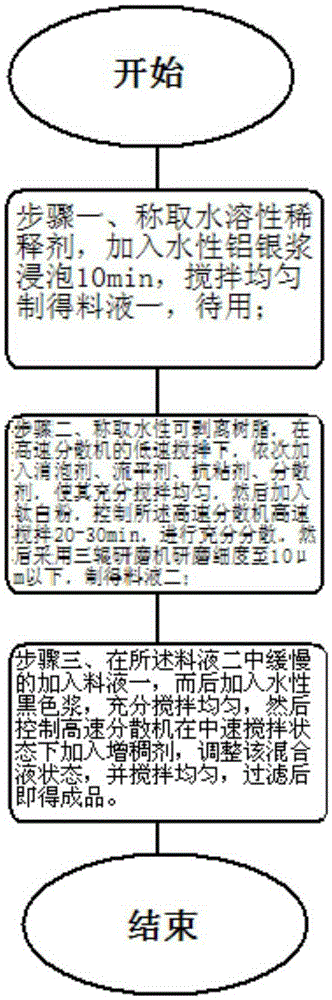

[0046] Preferred embodiments of the present invention are described in detail below in conjunction with accompanying drawings;

[0047] refer to figure 1 Shown, a kind of screen printing water-based scraping ink and preparation method thereof, wherein:

[0048] A water-based squeegee ink for screen printing, its components are calculated by mass percentage, including: water-based peelable resin: 30-60%, defoaming agent: 0.1-2%, leveling agent: 0.1-3%, anti-foaming agent: Viscosity: 2-5%, dispersant: 0.5-3.5%, thickener: 2-6%, water-soluble diluent: 8-20%, titanium dioxide: 5-20%, water-based aluminum silver paste: 10- 30%, water-based black pulp: 0.1-5%;

[0049] A group of preferred embodiments, through experiments to obtain the optimal scraping ink formula components, by mass percentage, including: water-based peelable resin: 45%, defoamer: 0.7%, leveling agent: 0.3%, anti-adhesive Agent: 2.1%, dispersant: 2.9%, thickener: 5%, water-soluble diluent: 10%, titanium dioxide:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com