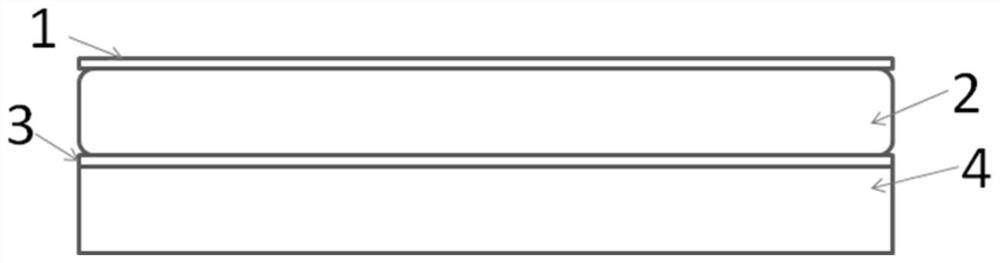

A kind of high-foaming high-stripping solvent-free shoe leather and its preparation method

A solvent-free, high-stripping technology, applied in the field of synthetic leather, can solve the problems of affecting the touch and flex resistance of synthetic leather, the synthetic leather feels hard, and the foam layer is difficult to foam, so as to achieve a green and pollution-free production process, durable Excellent flexure and improved peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of high-foaming and high-stripping solvent-free shoe leather, comprising the following steps:

[0035] (1) Weigh 80 parts of water-based PU, 2 parts of cross-linking agent, 0.4 parts of water-based thickener, 0.2 parts of leveling agent, and 6 parts of water-based color paste, uniformly stir to obtain water-based PU surface layer slurry, and mix the water-based PU surface layer slurry The material is coated on the release paper with a coating thickness of 0.12±0.01mm, and is dried in an oven to form a water-based PU surface layer. The temperature of the oven is divided into three temperature sections, and the temperature is 85±5℃, 95±5℃ , 105±5℃, the coating speed is controlled at 7±1m / min, and the oven length is 9m;

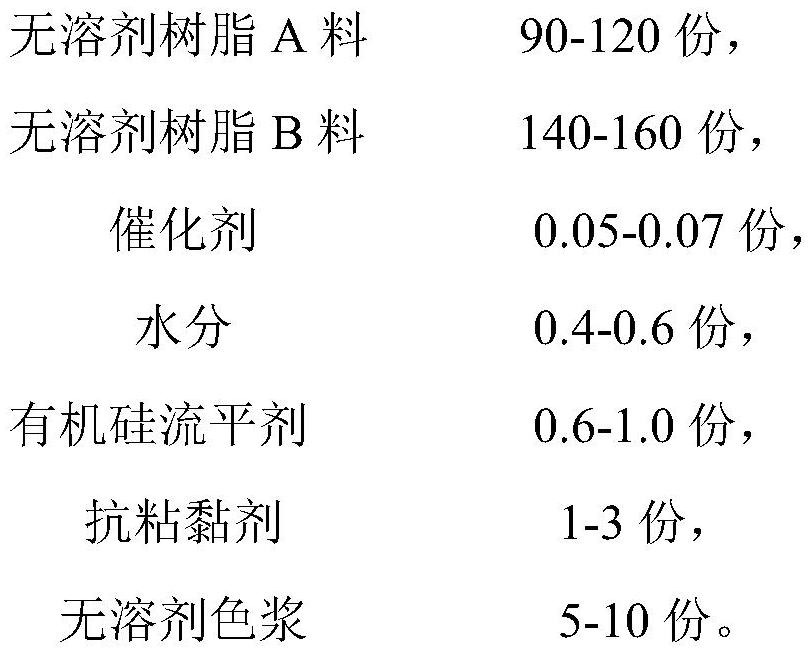

[0036](2) Accurately weigh 90 parts of solvent-free resin material A, 0.05 parts of catalyst, 6 parts of silicone leveling agent, 0.4 parts of moisture, 5 parts of solvent-free color paste, and 1 part of anti-sticking agent according ...

Embodiment 2

[0039] A preparation method of high-foaming and high-stripping solvent-free shoe leather, comprising the following steps:

[0040] (1) Weigh 110 parts of water-based PU, 4 parts of cross-linking agent, 0.8 parts of water-based thickener, 0.4 parts of leveling agent, and 10 parts of water-based color paste, uniformly stir to obtain water-based PU surface layer slurry, and mix the water-based PU surface layer slurry The material is coated on the release paper with a coating thickness of 0.12±0.01mm, and is dried in an oven to form a water-based PU surface layer. The temperature of the oven is divided into three temperature sections, and the temperature is 85±5℃, 95±5℃ , 105±5℃, the coating speed is controlled at 7±1m / min, and the oven length is 9m;

[0041] (2) Accurately weigh 120 parts of solvent-free resin material A, 0.07 parts of catalyst, 10 parts of silicone leveling agent, 0.6 parts of moisture, 10 parts of solvent-free color paste, and 3 parts of anti-sticking agent acc...

Embodiment 3

[0044] A preparation method of high-foaming and high-stripping solvent-free shoe leather, comprising the following steps:

[0045] (1) Weigh 95 parts of water-based PU, 3 parts of cross-linking agent, 0.6 parts of water-based thickener, 0.3 parts of leveling agent, and 8 parts of water-based color paste, uniformly stir to obtain water-based PU surface layer slurry, and mix the water-based PU surface layer slurry The material is coated on the release paper with a coating thickness of 0.12±0.01mm, and is dried in an oven to form a water-based PU surface layer. The temperature of the oven is divided into three temperature sections, and the temperature is 85±5℃, 95±5℃ , 105±5℃, the coating speed is controlled at 7±1m / min, and the oven length is 9m;

[0046] (2) Accurately weigh 105 parts of solvent-free resin material A, 0.06 parts of catalyst, 8 parts of silicone leveling agent, 0.5 parts of moisture, 7 parts of solvent-free color paste, and 2 parts of anti-sticking agent accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com