Damping infilled wall of RC frame structure and manufacturing method of damping infilled wall

A frame structure and manufacturing method technology, applied in the field of shock-absorbing infill walls, can solve problems such as stress redistribution, brittle failure of frame structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

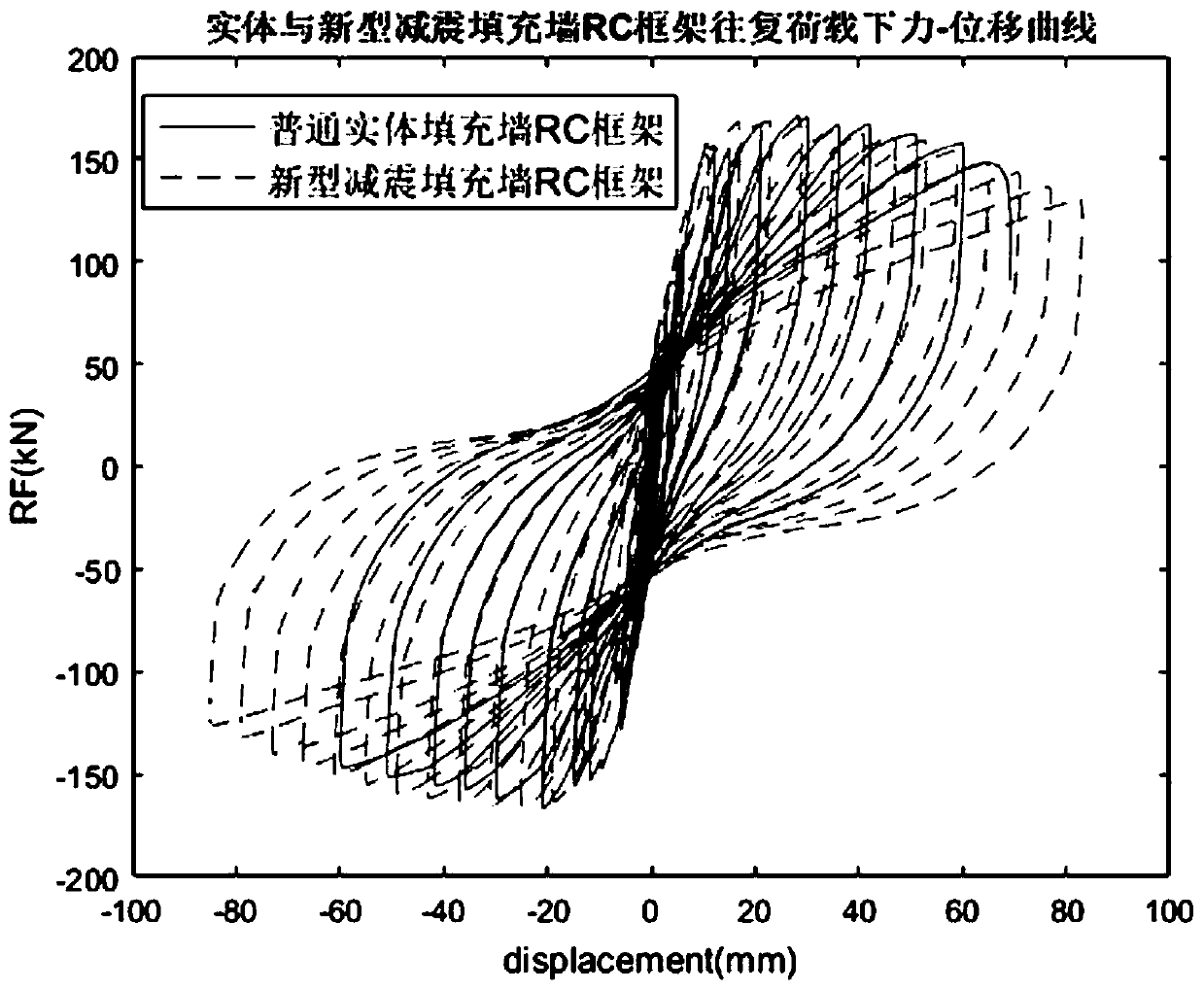

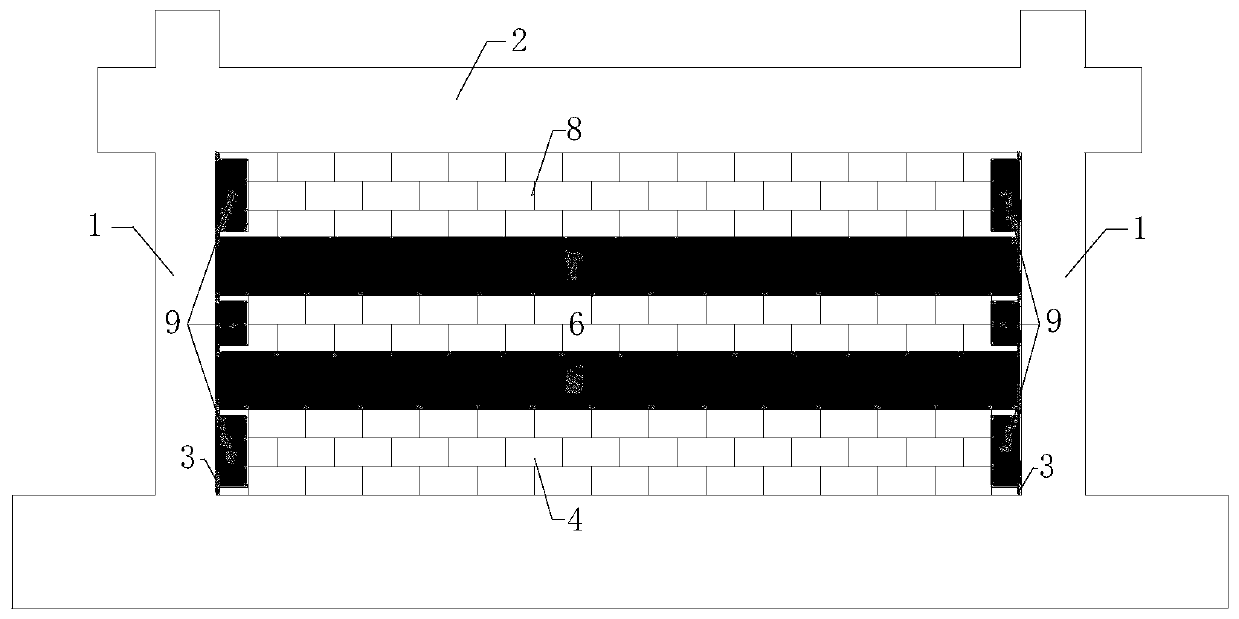

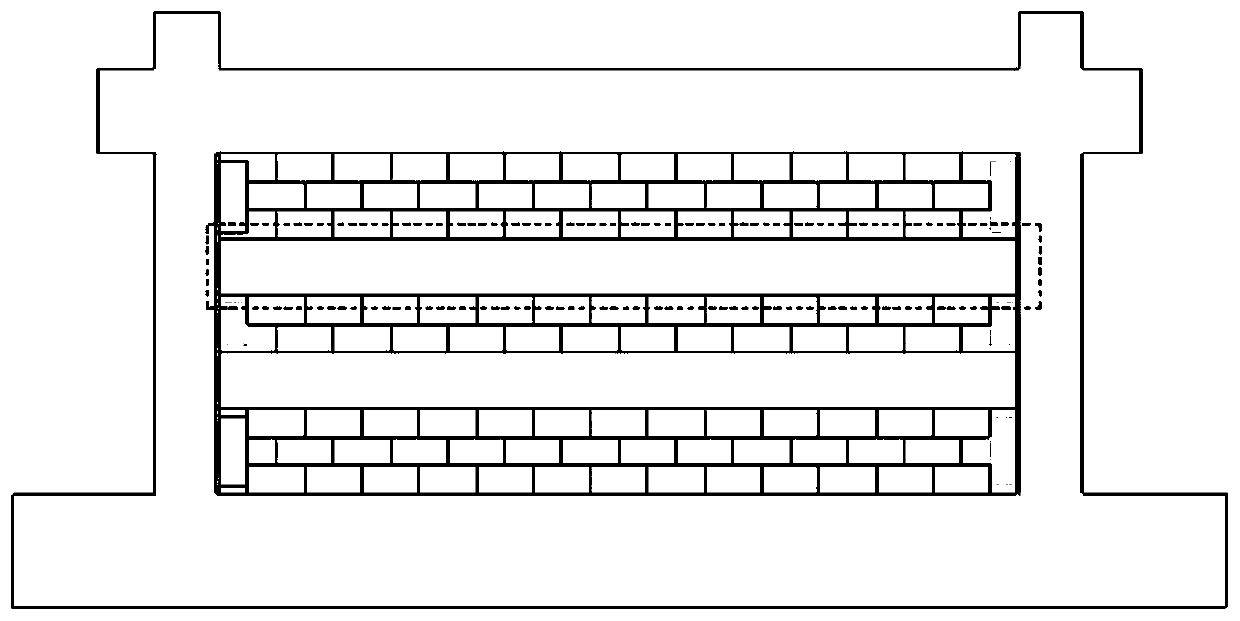

[0033] Specific implementation mode one: see Figure 1-Figure 8 This embodiment will be described. The shock-absorbing infill wall of the RC frame structure described in this embodiment includes a masonry structure built in a space surrounded by frame columns 1 and frame beams 2. The masonry structure includes several transverse steel bars, steel plates 3 inside the columns, The bottom wall body 4, the first layer H-shaped slide rail 5, the middle layer wall body 6, the second layer H-shaped slide rail 7, the top layer wall body 8 and several out-of-plane protective steel plates 9; Steel plate 3, a number of transverse steel bars are welded between the inner steel plates 3 of the two columns, and the bottom wall 4, the first H-shaped slide rail 5, the middle wall 6, The second layer of H-shaped slide rails 7 and the top wall 8, the top wall 8 is in contact with the frame beam 2 at the top, and the bottom wall 4, middle wall 6 and top wall 8 are in contact with the steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com