Flexible pipe radiator based on fluorine plastic pipe

A fluoroplastic tube and flexible tube technology, which is applied in the field of flexible tube radiators to achieve the effect of increasing surface area and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

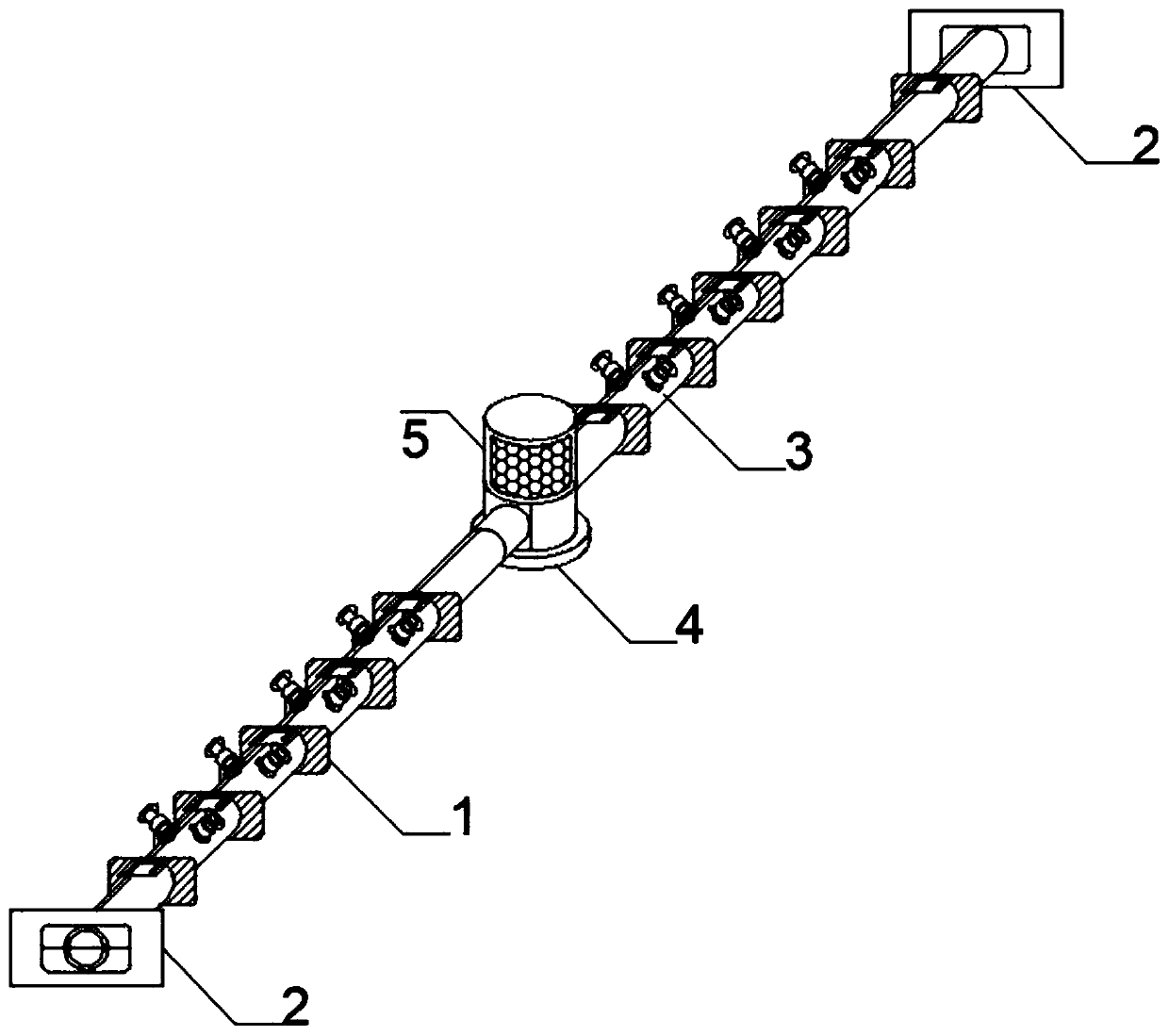

[0030] as attached figure 1 to attach Figure 5 Shown:

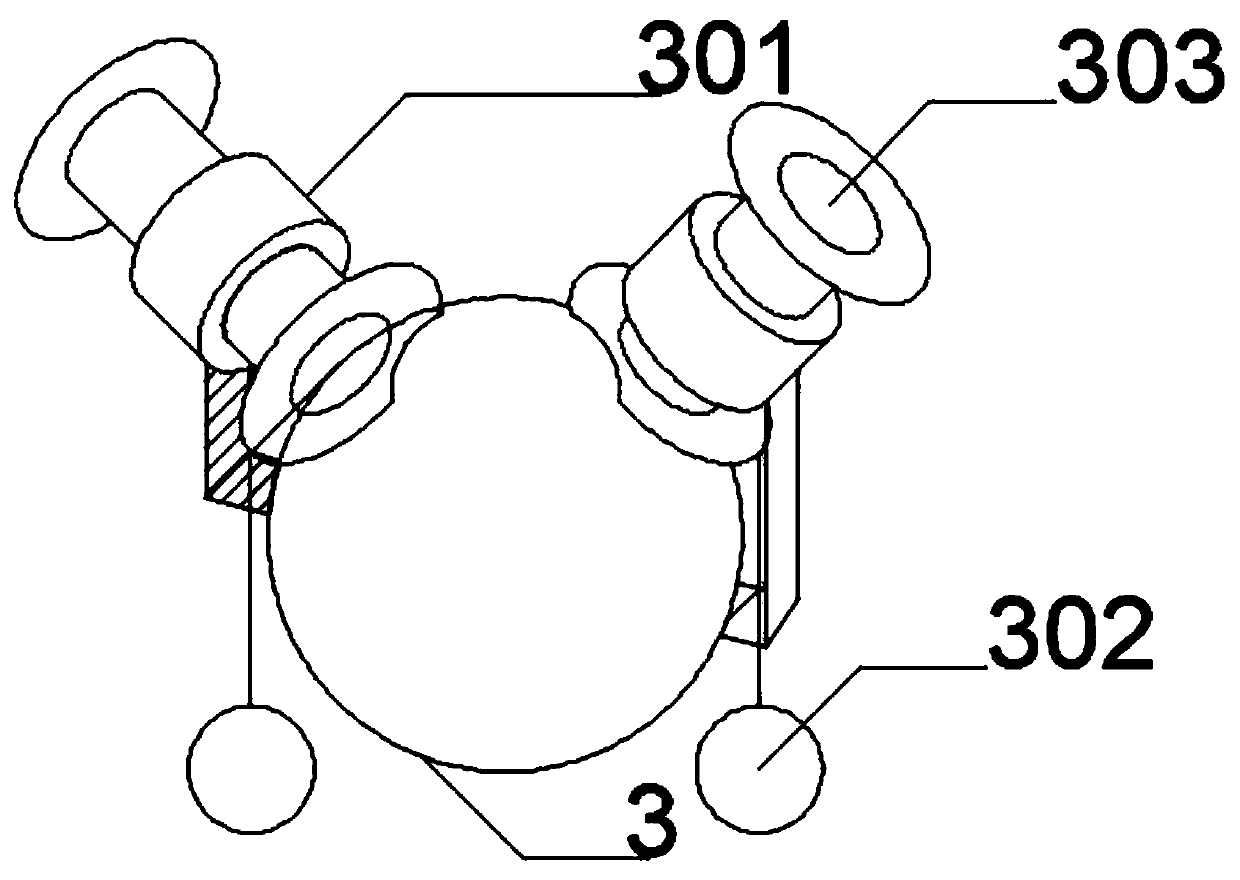

[0031] The invention provides a flexible tube radiator based on a fluoroplastic tube, which includes a main cooling fin 1, a terminal cooling fin 2, a connecting rib 3, a middle ground node 4 and an independent fan 5; the center of the main cooling fin 1 is provided with a circle shaped hole, and the four endpoints of the two lines perpendicular to each other on the edge of the round hole of the main cooling fin 1 are connected to the connecting rib 3 by welding; the connecting rib 3 is connected to several main cooling fins 1 by welding; the connection The bottom of the middle end of the rib 3 is connected with a middle ground node 4 by welding, and the center of the middle ground node 4 is open; The top is connected by screws and an independent fan 5 is installed.

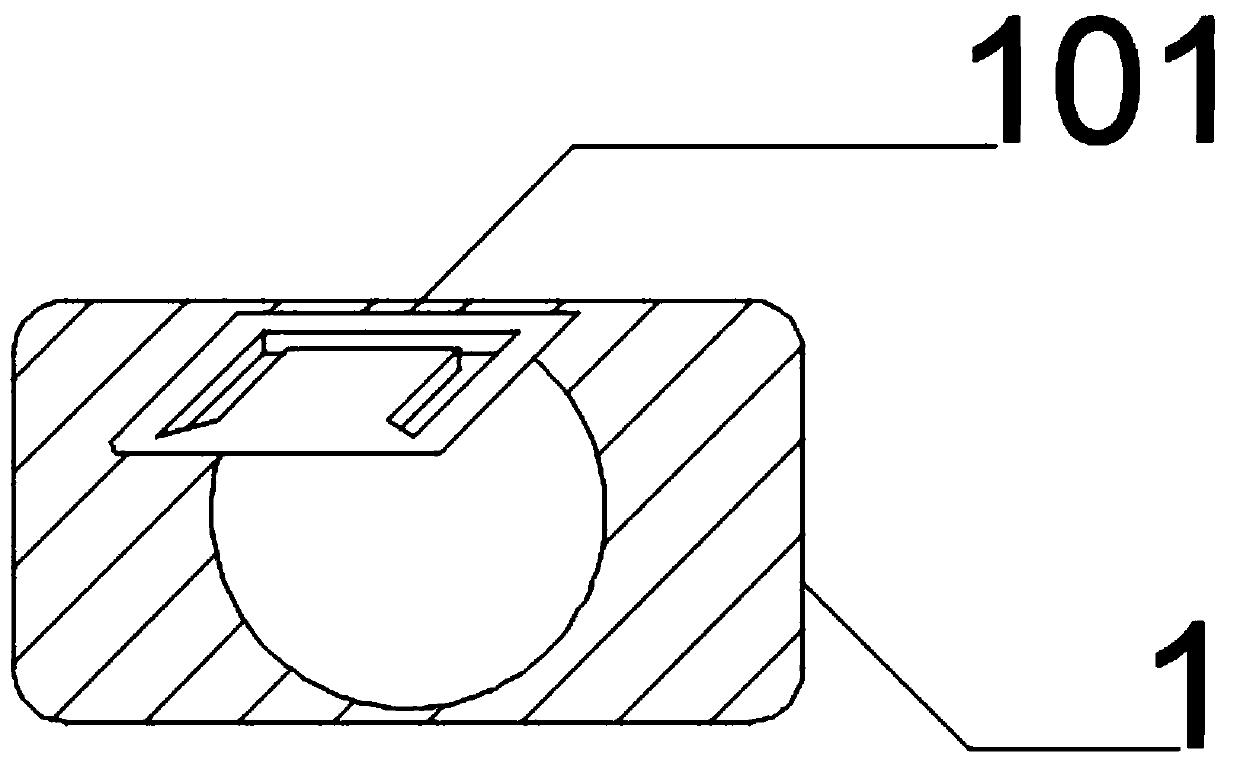

[0032] Wherein, above the round hole on the front surface of the main heat dissipation fin 1, a secondary fin 101 is installed through welding connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com