Small-aperture 16-component conical strain gauge

A technology of strain gauge and small aperture, which is applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of long cycle time, short cycle time, low stress test rate, etc., and achieve high test efficiency and ground Accurate stress measurement results and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

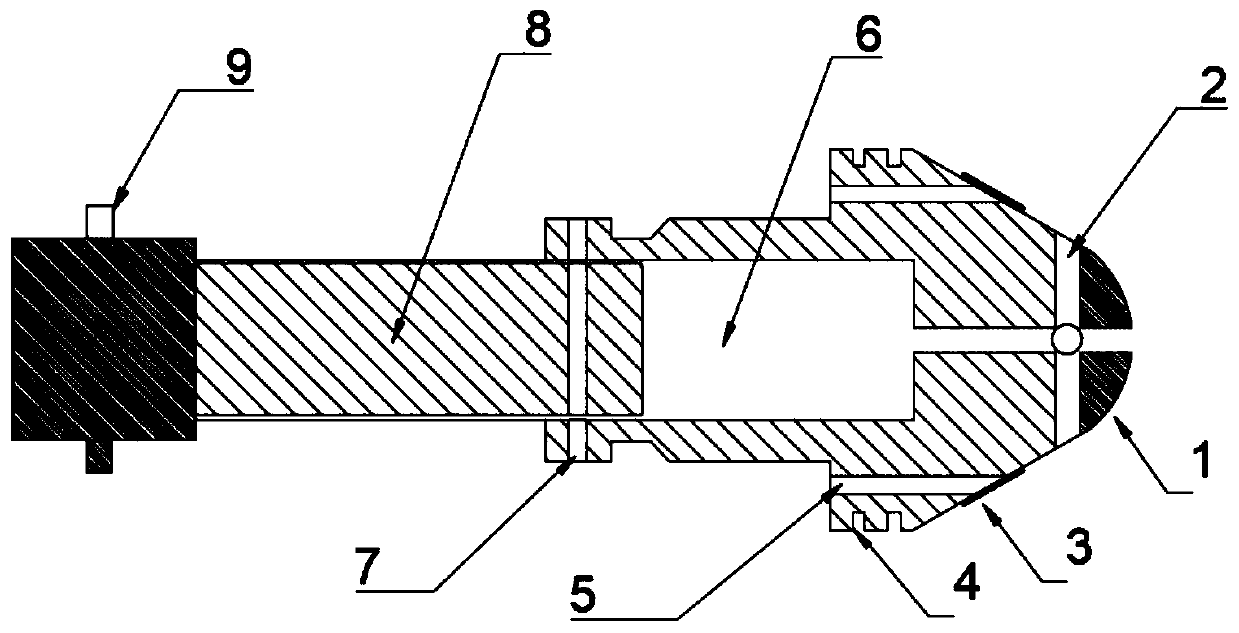

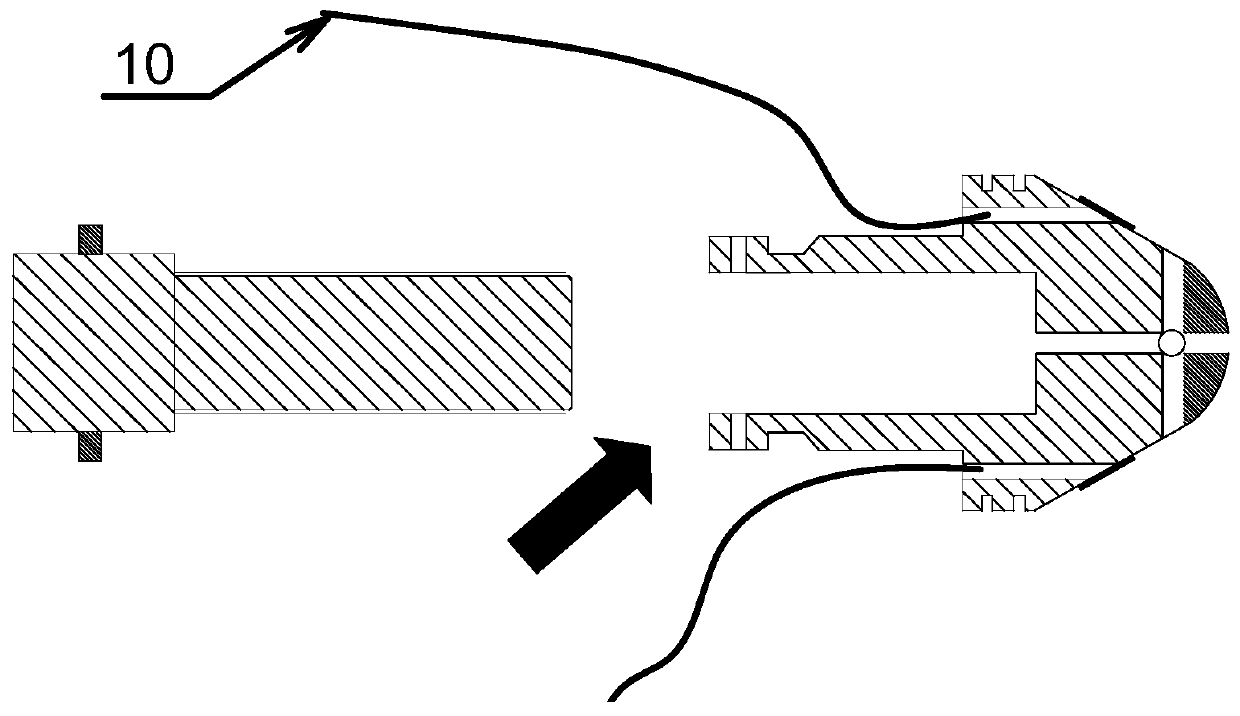

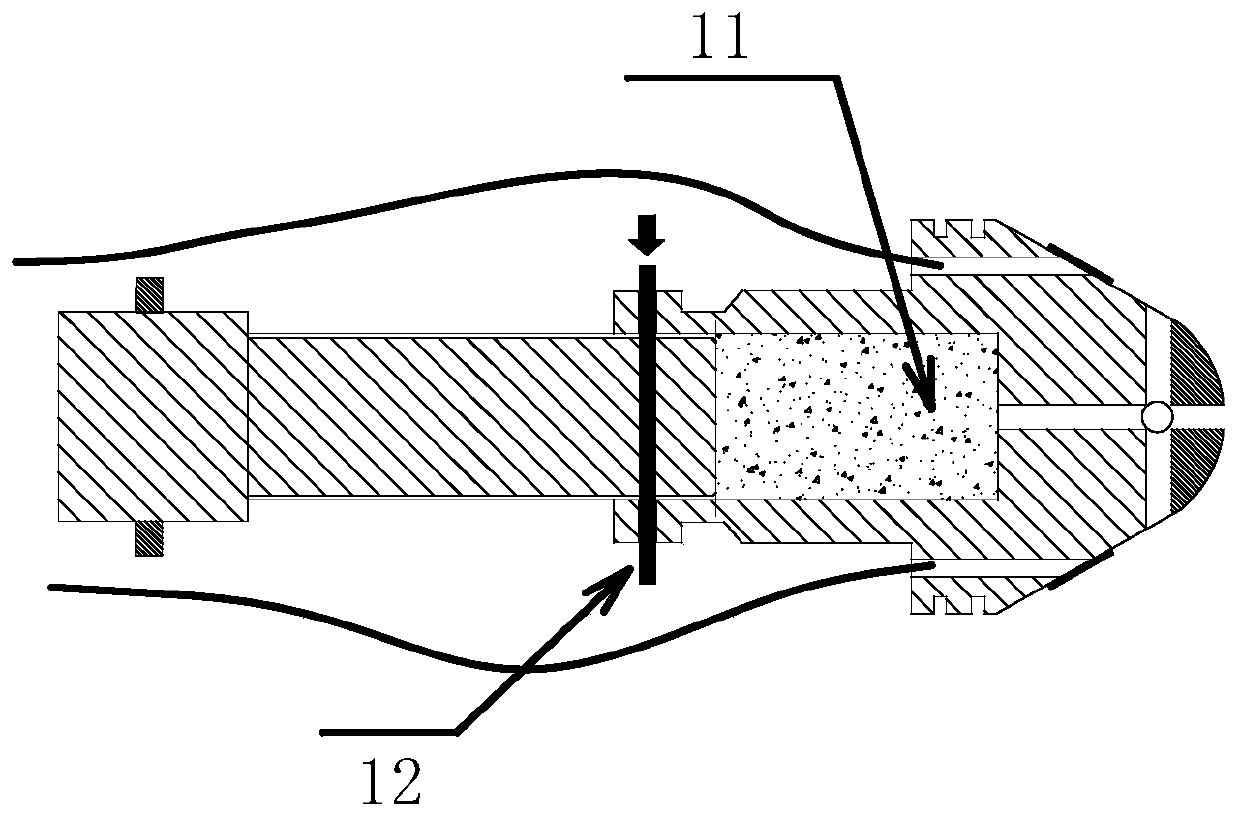

[0025] Small aperture 16-component conical strain gauge, including aluminum cap 1, glue outlet hole 2, strain gauge and paste groove 3, adhesive retaining ring 4, lead hole 5, glue storage chamber 6, temporary fixing hole 7, piston Rod 8, positioning pin 9 is installed.

[0026] There are 16 sets of strain gauges in total, and 2 sets of strain gauges are attached to each sticking groove. The first set of strain gauges is set horizontally, and the second set of strain gauges is set vertically to the first set of strain gauges. The sticking grooves are evenly distributed along the circumference of the tapered strain head. The angle between adjacent pasting grooves is 45°. The outer edge of the adhesive retaining ring 4 exceeds the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com