Accurate modeling method of electromechanical actuation system friction pair

A technology of electromechanical actuation and modeling methods, applied in general control systems, control/regulation systems, electrical digital data processing, etc., can solve problems such as slow convergence speed and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with drawings and embodiments.

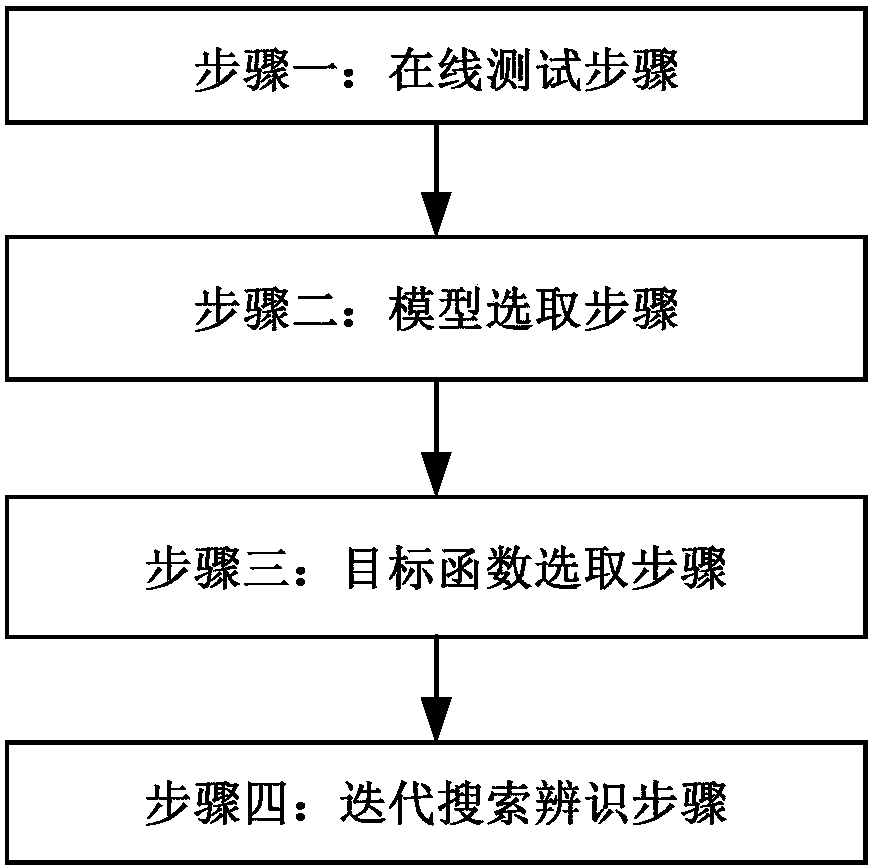

[0068] The present invention is specifically an accurate modeling method for the friction pair of an electromechanical actuating system based on the Stribeck friction model and the simulated annealing genetic algorithm. The flow chart of the steps is as follows figure 1 As shown, it specifically includes the following steps:

[0069] Step 1: Online testing steps. First, make the electromechanical servo system work under constant speed control, and test the corresponding torque at different speeds.

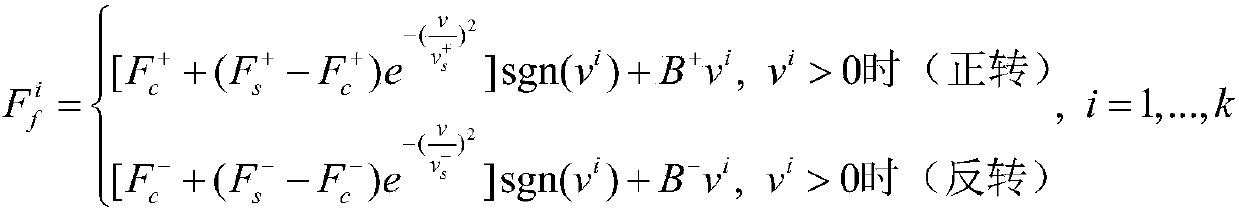

[0070] Step 2: Model selection step. The friction model suitable for the electromechanical servo system is selected, the parameters to be identified are determined according to the selected friction model, and the identification value sequence and identification error sequence of the calculated friction torque are further obtained.

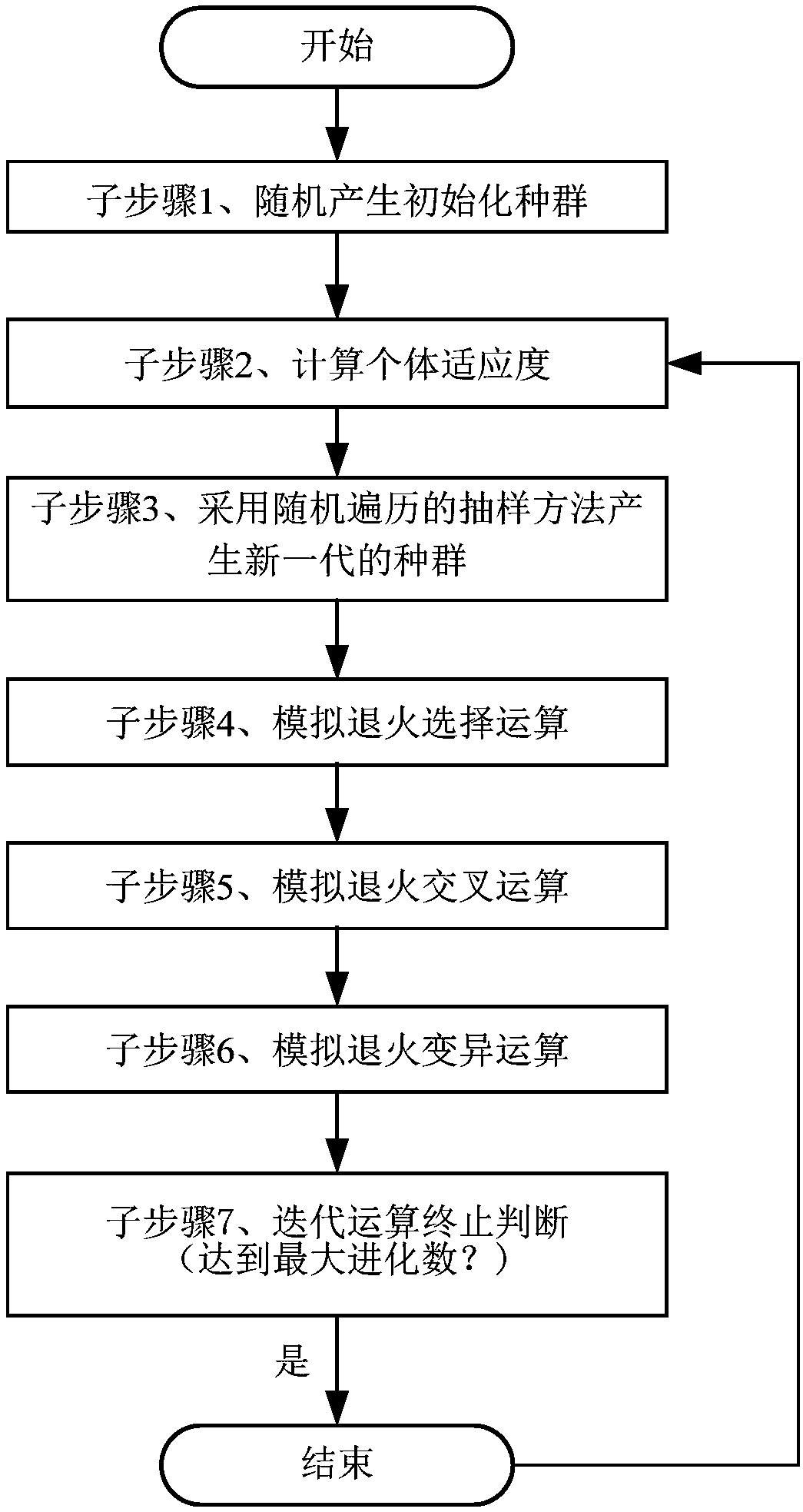

[0071] Step 3: Objective function sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com