True triaxial test system and method for simulating influence of different temperatures on deep rock mass

A test system, true triaxial technology, applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, measurement devices, etc., can solve the problem of lack of simulation of the real environment of deep rock mass, to solve the problem of loading eccentricity, The effect of reducing the difficulty of handling and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the present invention, the side close to the rock sample 6 is considered as the inside, and vice versa as the outside.

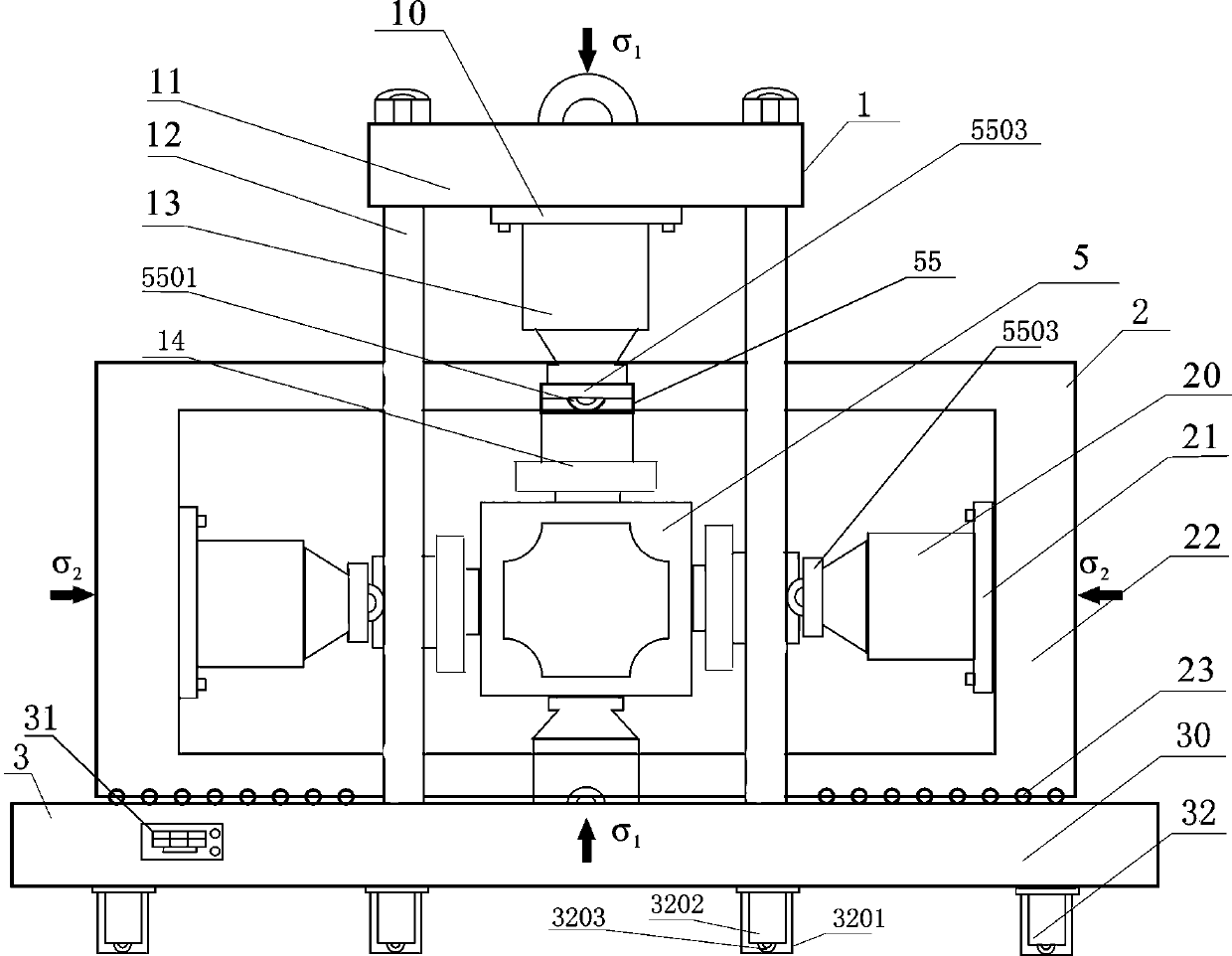

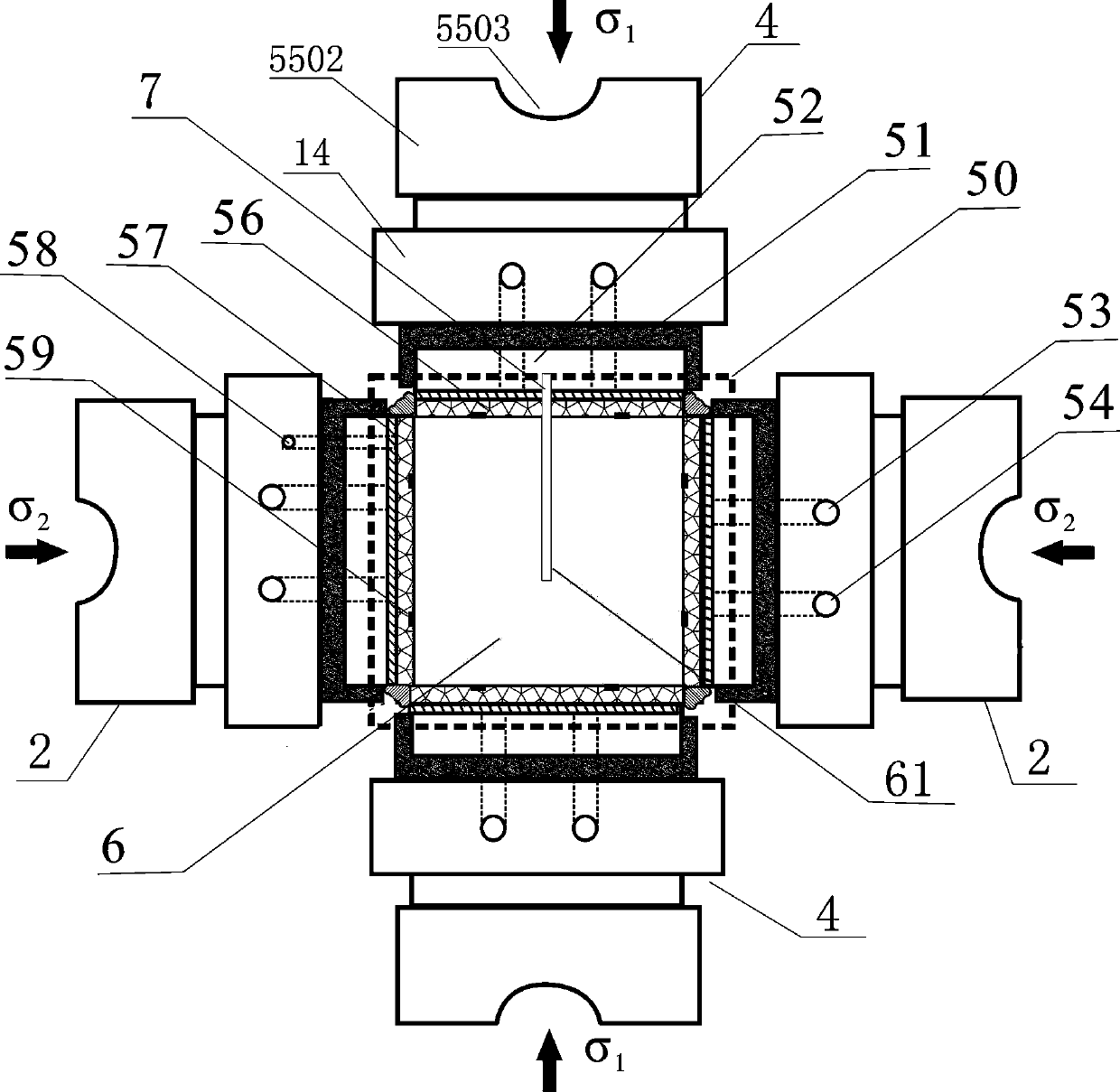

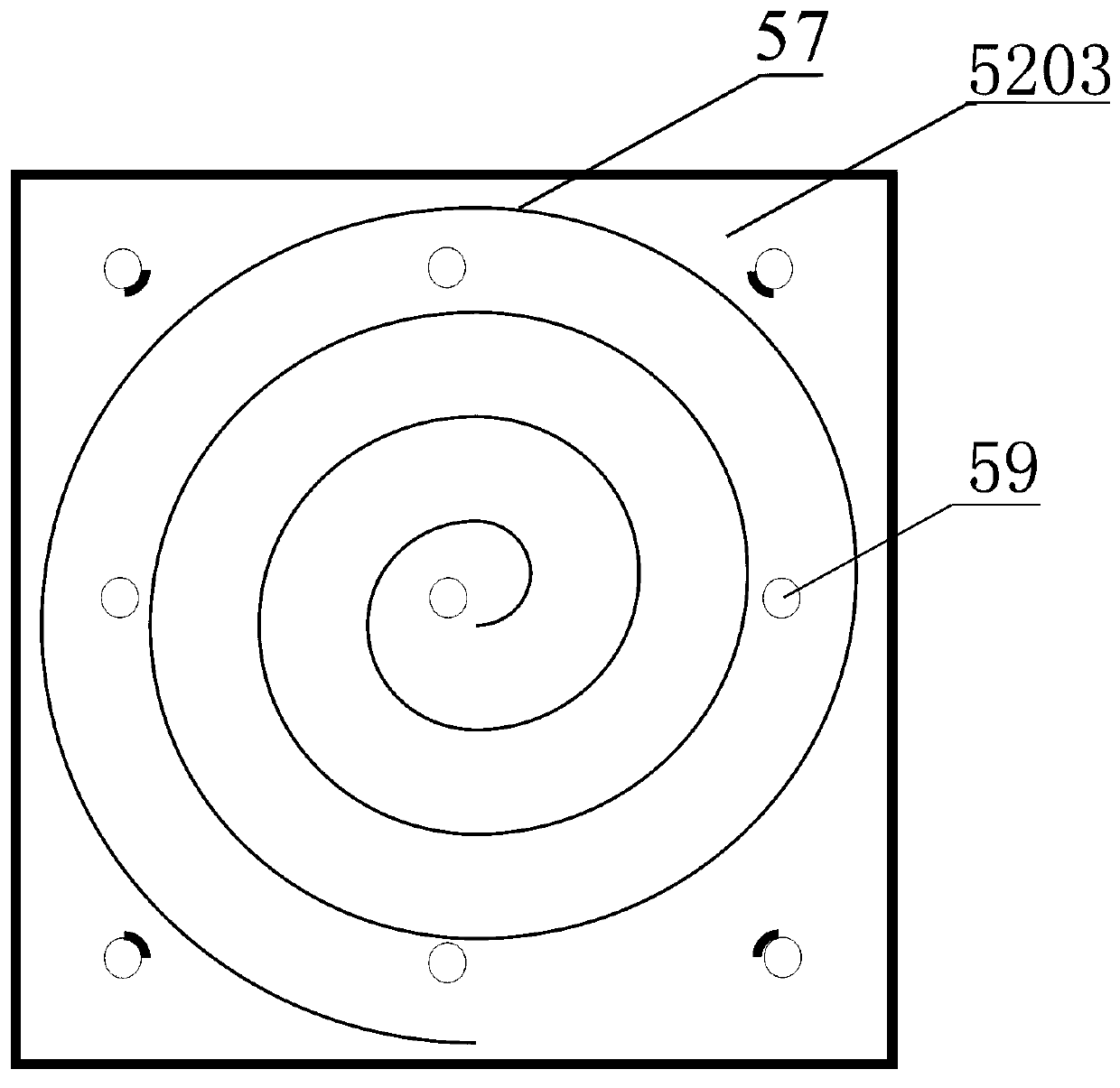

[0037] Such as figure 1 , figure 2 As shown, a true triaxial test system for simulating the influence of different temperatures on deep rock mass, including a rolling table 3, the upper surface of the rolling table 3 is provided with X-guiding rails and Y-guiding rails that cross each other perpendicularly, and the X-direction The guide rail and the Y-guiding rail are two parallel X-rails (not shown in the figure) and two parallel Y-rails (not shown in the figure) respectively, and two symmetrically arranged X-direction centers are movably installed on the X-guiding rail. The main stress loading mechanism 2, two Y-direction small main stress loading mechanisms 4 symmetrically installed on the Y-direction rail, two X-direction middle main stress loading mechanisms 2 and two Y-direction small main stress loading mechanisms 4 are symmetrical The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com