Dynamic part average testing (DPAT) method for automatic test equipment (ATE) system

A test method and post-test technology, applied in the field of DPAT test, can solve problems such as prolonging the test cycle, wasting time and resources, failing to link test and sorting results to components, etc., so as to improve mass production efficiency and prevent manual errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

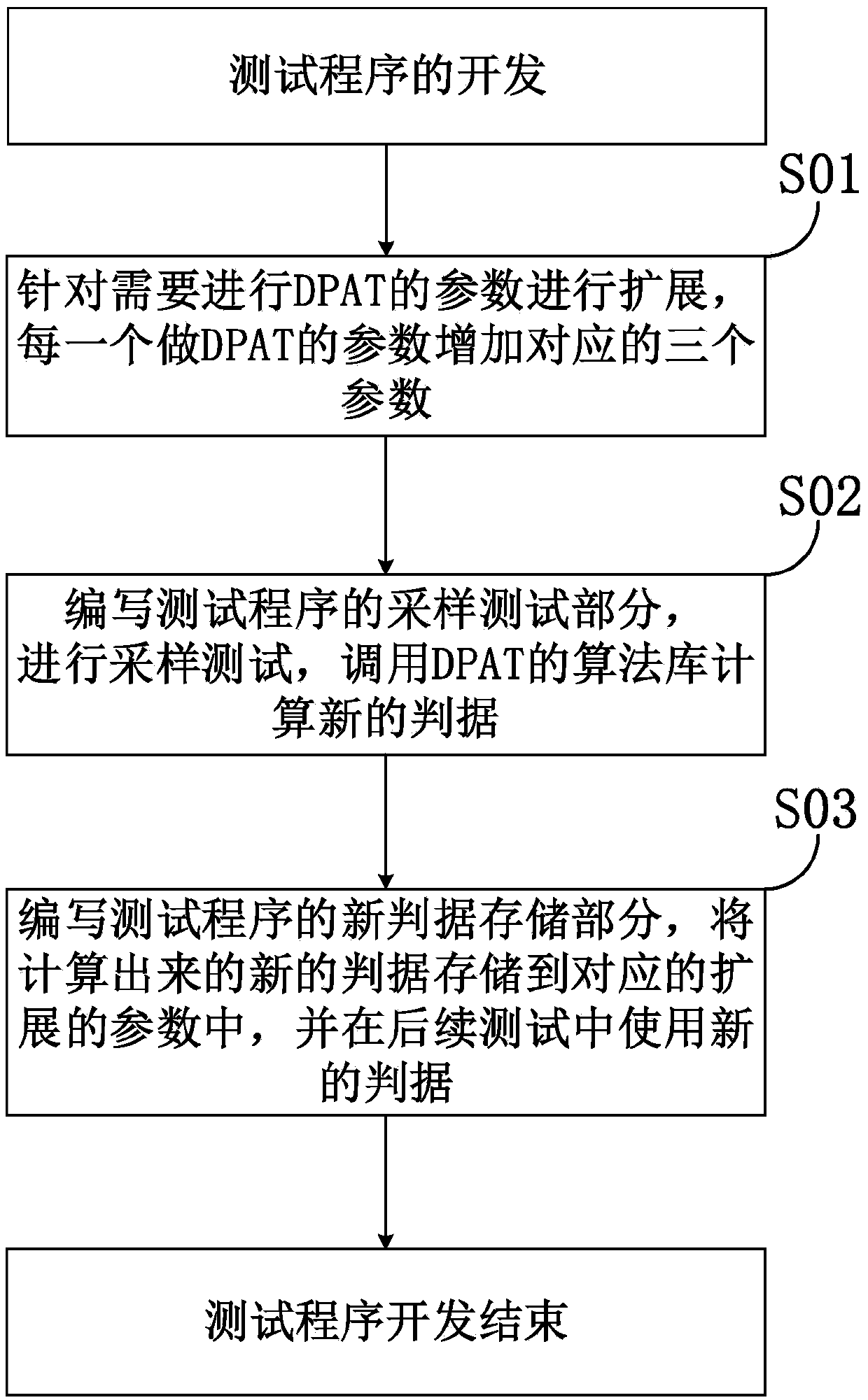

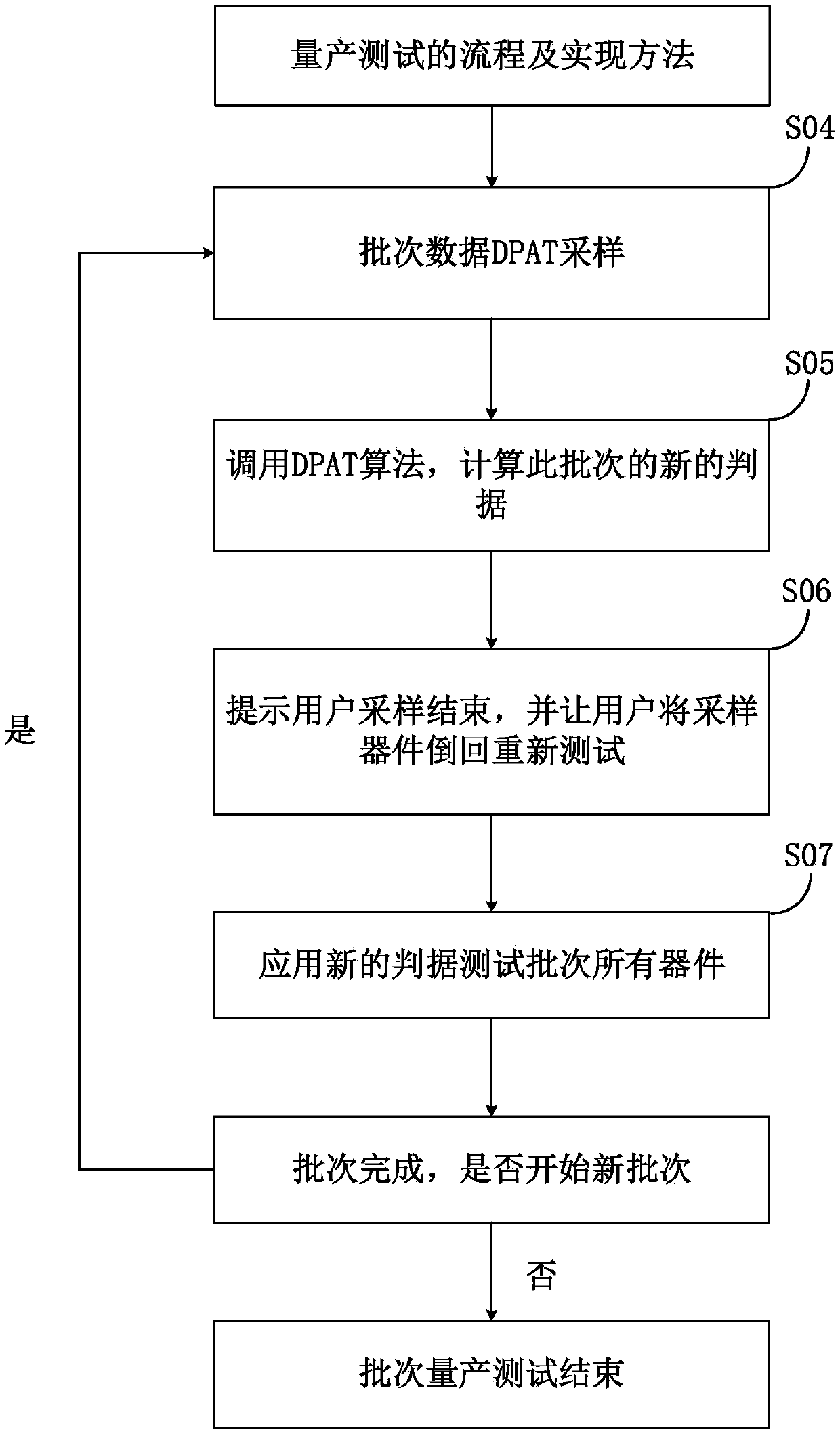

[0043] The main purpose of the present invention is to provide a kind of DPAT test method for ATE system, by carrying out sampling test to the part product of current batch, select new criterion according to the data distribution of sampling test, and utilize new criterion Conduct mass production testing. Through the present invention, without affecting the test time and uninterrupted test process, each product in the mass production test can be screened and graded, and new criteria can be switched in real time according to the characteristics of the current batch of products , less time-consuming and less error-prone, improving mass production efficiency.

[0044] Below, refer to figure 1 ~ as image 3 As shown, the DPAT test method for the ATE system described in the present invention will be described in detail.

[0045] Such as figure 1 As shown, the DPAT test method for ATE system provided by the present invention is divided into two parts:

[0046] S100: test progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com