Micro-adjustment method for coordinate position of equipment

A technology of micro-adjustment and equipment coordinates, which is applied in the direction of program control in control/regulation systems, instruments, sequence/logic controllers, etc., can solve problems such as limiting the scope of use, and achieve the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

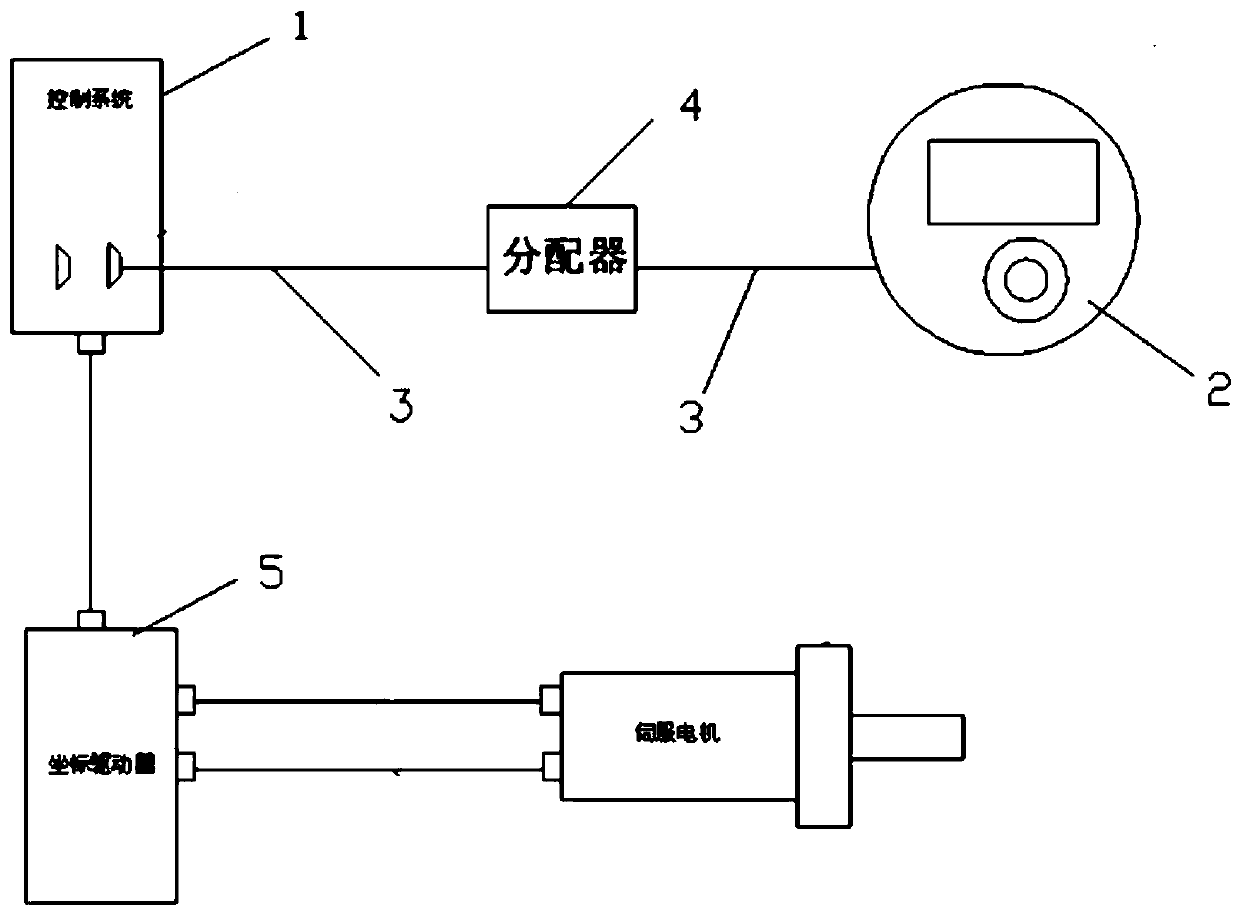

[0016] The principle of the present invention will be described below in conjunction with the accompanying drawings.

[0017] exist figure 1 Among them, a method for micro-adjustment of equipment coordinate position, including the following steps:

[0018] Step 1. Connect the hand-operated counter 2 with the machine tool control system 1. The signal of the hand-operated counter is transmitted to the distributor 4 through the PLC communication bus 3. After the distributor 4 shapes and recodes the signal, it is converted into a signal that is compatible with the control system. 1 to match the signal. .

[0019] Step 2: Add a coordinate position fine-tuning control subroutine in the PLC control main program.

[0020] Two independent variables are set in the coordinate position fine-tuning control subroutine to respectively record the number of grids that the hand counter 2 rotates in positive and negative directions. The positive and negative correspond to the moving direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com