A locking, unlocking, grabbing and lifting device for lead-based reactor fuel assemblies

A technology for lead-based reactors and fuel components, applied in the direction of reactor fuel elements, assembly of fuel elements, reactors, etc., can solve the problem of fuel assembly moving up and down, difficult to withstand the high temperature of liquid lead-bismuth coolant, high corrosion and high radiation environment seismic load synthesis Function and other issues, to achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] When feeding, it is necessary to unlock the spent fuel assembly from the core grid plate 5 and put out the lead-based reactor core (the state before feeding is as follows: Figure 21 shown), the steps include:

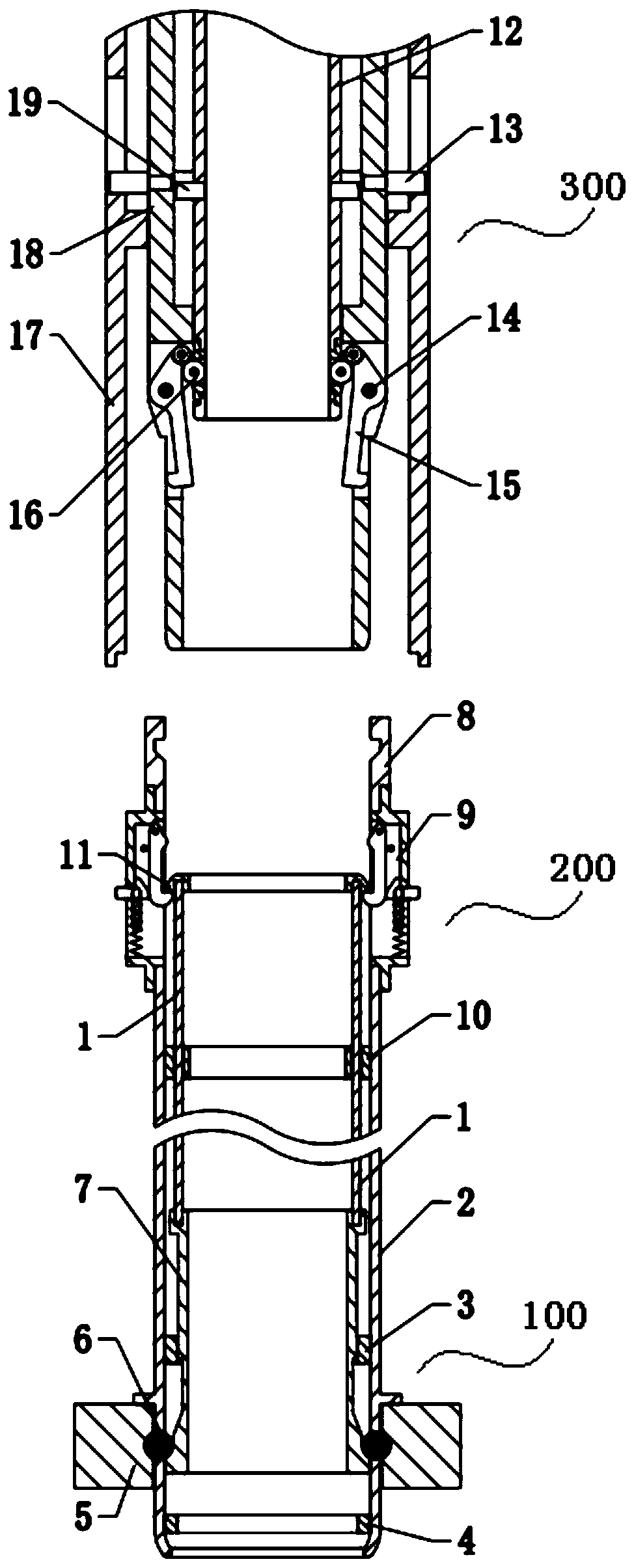

[0091] In the first step, the refueling head mechanism 300 moves to the top of the upper pipe seat self-locking mechanism 200, and the outer pusher 17 of the refueling head mechanism 300 moves downwards to meet the side ear 961 of the slider 96 in the hook box 91. Contact, make it overcome the buoyancy of spring 951 resistance and lead-based coolant, move down along guide pin 952, removed slide block 96 to the restraint that self-locking claw 93 rotates outwards around self-locking claw pin 92 ( The status is as Figure 22 shown);

[0092] In the second step, the middle push cylinder 18 of the refueling head mechanism 300 moves downward. First, the outer edge of the lower end of the middle push cylinder 18 will push the protrusion on the inner wall surface of ...

Embodiment 2

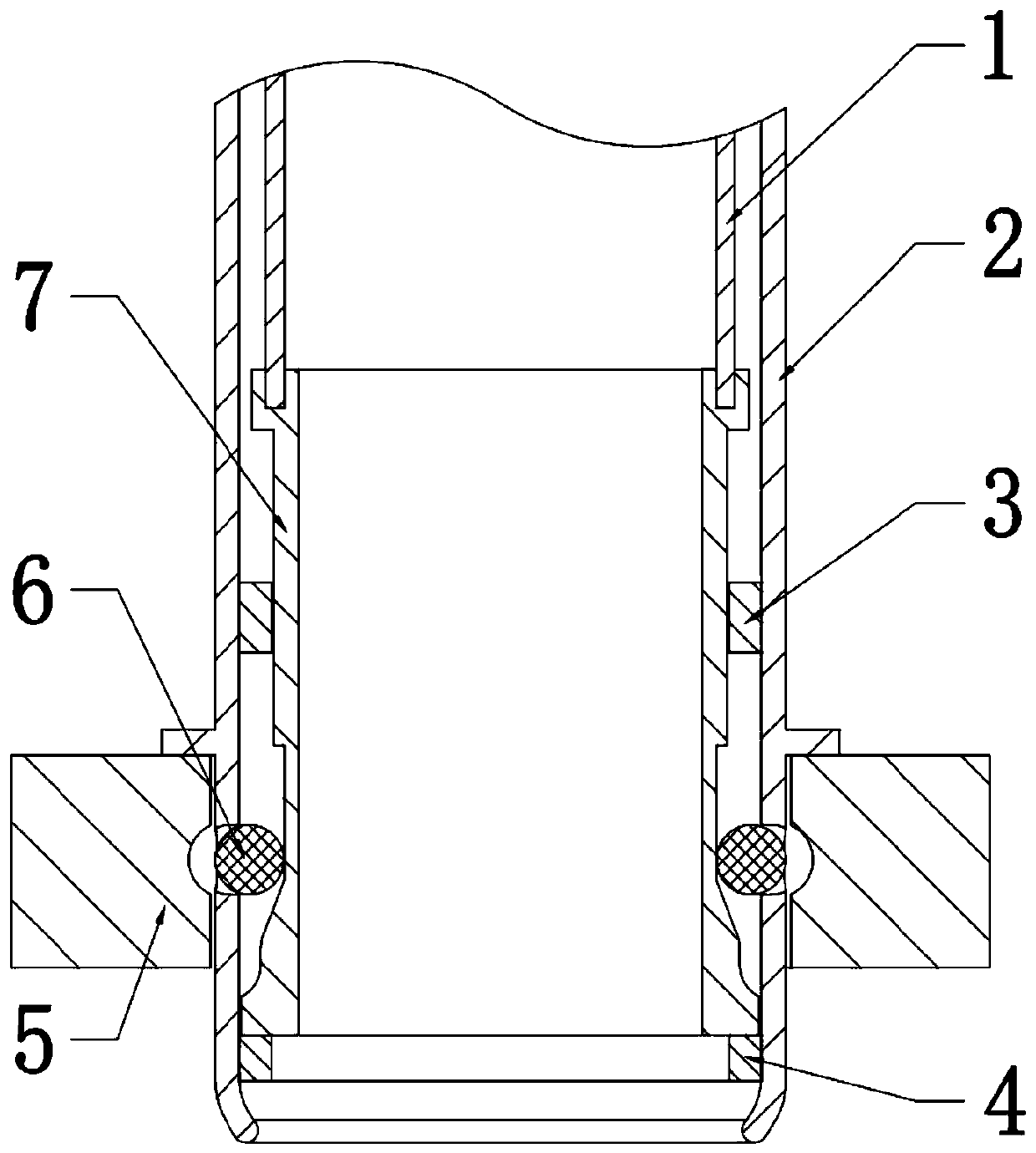

[0096] When charging, new fuel assemblies need to be placed in the core of the lead-based reactor. The fuel assembly moves down to the core grid plate 5 (this state is as Figure 26 shown), the steps include:

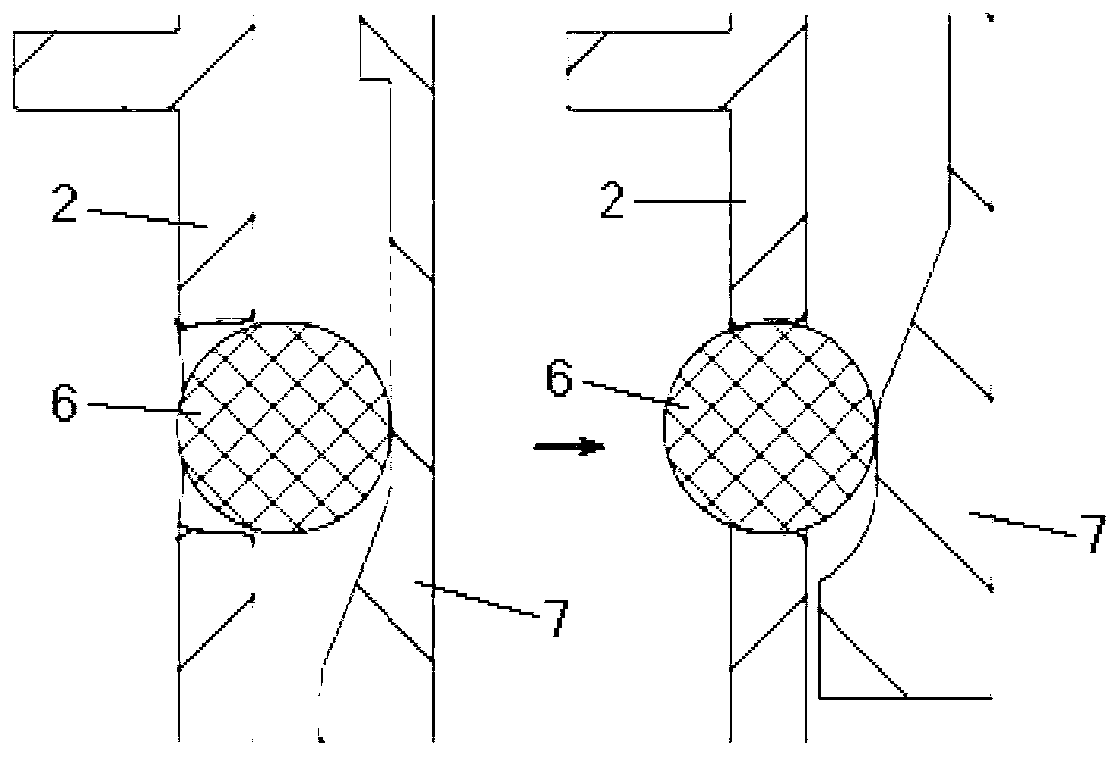

[0097] The first step is to insert the lower nozzle base 2 into the hole of the core grid plate 5, and after the limiting boss outside the lower tube base 2 contacts the core grid plate 5, the new fuel assembly moves vertically downward as a whole and is subject to pressure. Constraint, stop sinking (this state is as Figure 27 shown);

[0098] In the second step, the inner push cylinder 12 of the refueling head mechanism 300 is moved upwards, and the roller 161 of the roller box 16 is moved to the end arc surface of the inner wall surface of the locking claw 15, so that the locking claw 15 surrounds the locking claw Bearing pin 14 rotates to the inside, and now the connection between the locking hook 15 of the refueling head mechanism 300 and the upper pipe seat 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com