A method for improving the efficiency of circuit board silk screen soldering resistance

A technology of silk screen printing and solder resistance, which is applied in the field of improving the efficiency of circuit board silk screen solder resistance. It can solve the problems of low efficiency, hidden dangers, and easy oxidation quality of copper surface, etc., so as to improve production efficiency, save time, and conveniently and quickly disassemble or adjust. The effect of changing the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

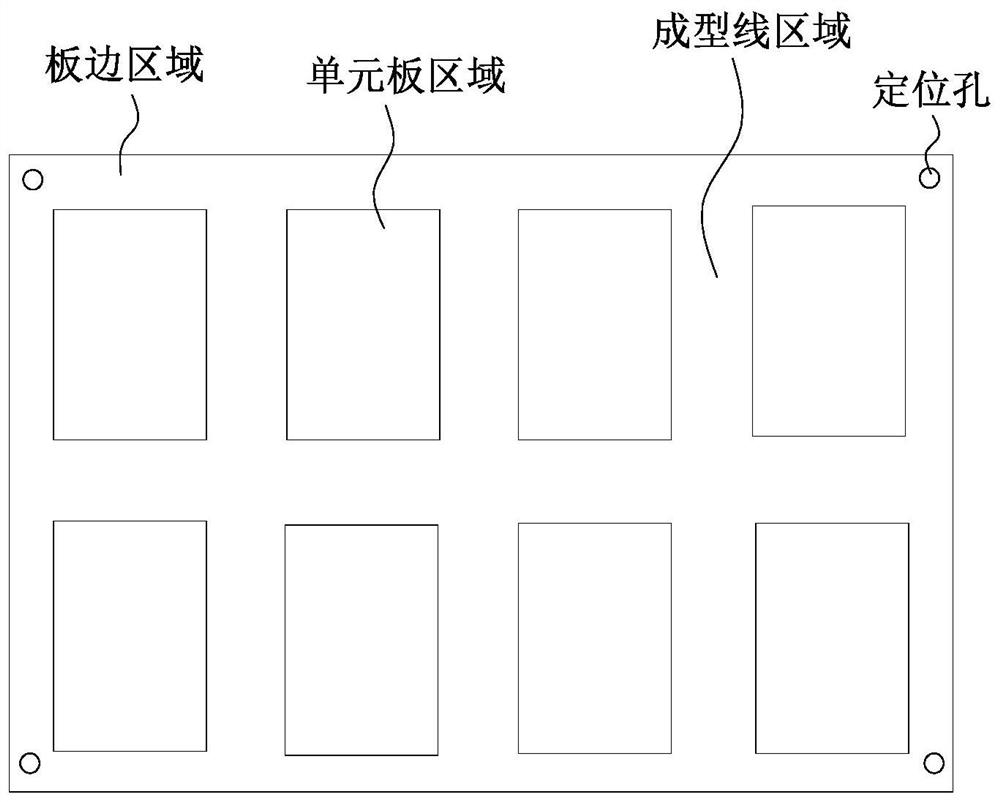

[0027] This embodiment provides a method for improving the efficiency of silk screen solder masking of circuit boards. The PCB production boards of silk screen solder masking are as follows: figure 1 As shown, the PCB production board is divided into the following areas: the board edge area, the unit board area, and the forming line area isolating each unit board area; positioning holes are provided on the board edge area at the four corners of the PCB production board.

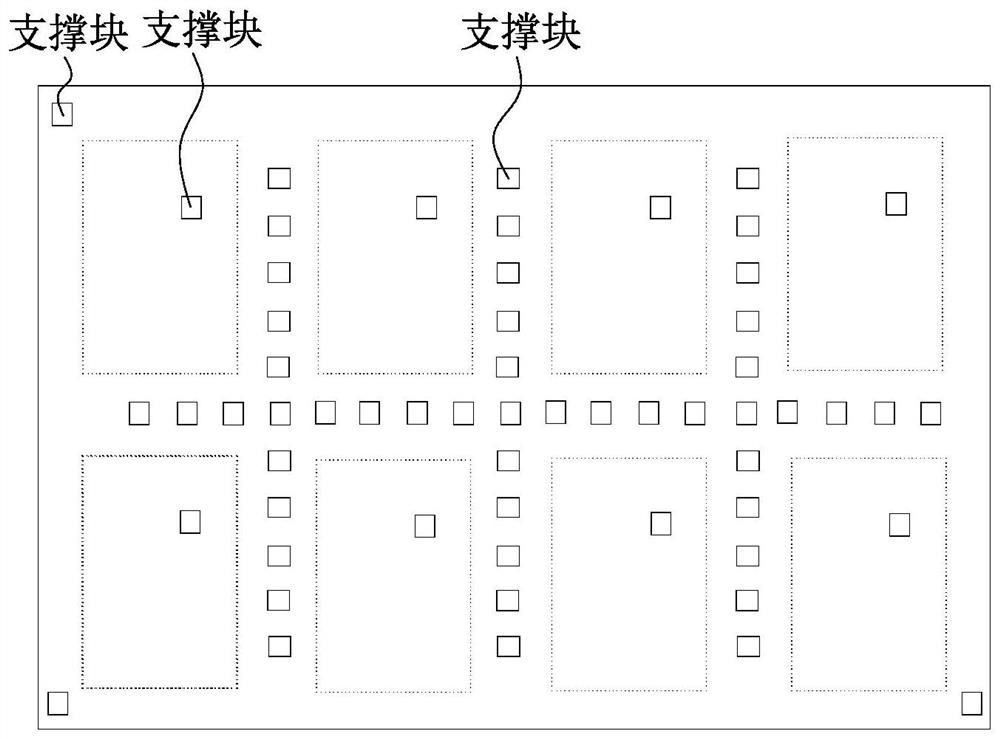

[0028] According to the size of the PCB production board and its area division, the silk screen auxiliary board is made, and the silk screen auxiliary board is 20mm larger than the single side of the PCB production board. The silk screen auxiliary board is divided into areas corresponding to the board edge area, the unit board area and the forming line area of the PCB production board, and the support is set on the board edge area at the triangle of the silk screen auxiliary board and at the position corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com