An anaerobic ammonia oxidation reactor

A technology of anaerobic ammonium oxidation and reactor, which is applied in the field of anaerobic ammonium oxidation reactor, can solve the problem that it is difficult to independently achieve high-efficiency and high-speed sewage denitrification treatment, affecting the efficiency of sewage denitrification treatment, low efficiency of sewage denitrification treatment, etc. problems, to achieve the effect of improving sewage treatment efficiency, great promotion and application significance, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

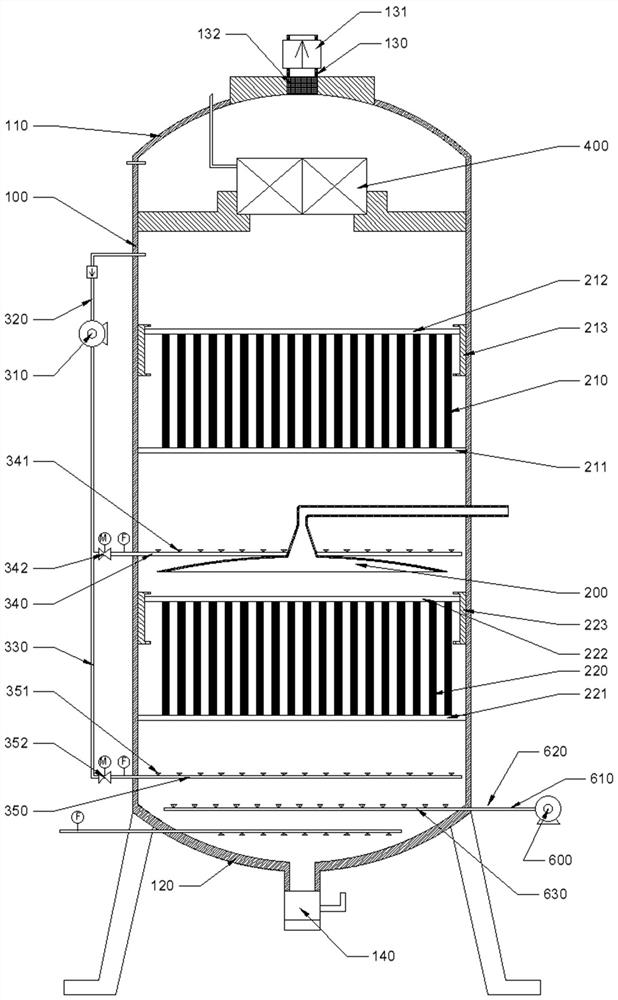

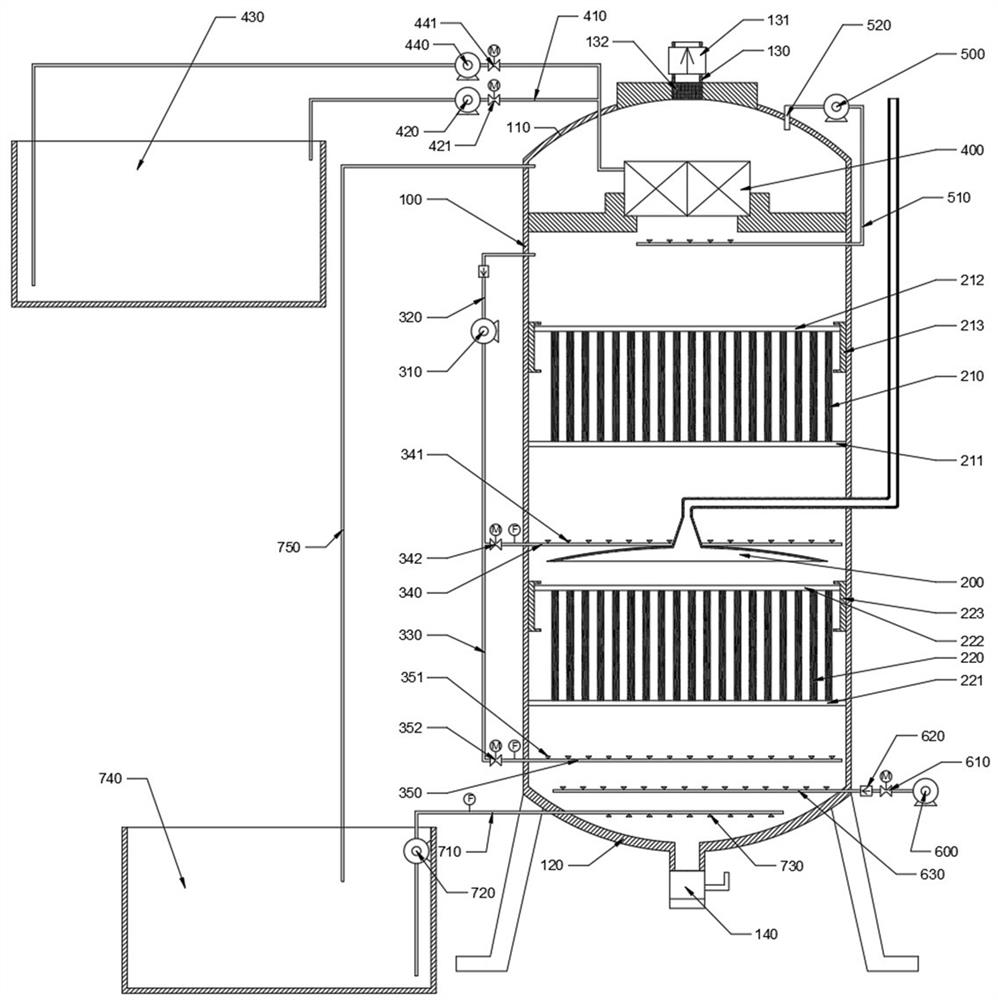

[0030] like figure 1 , figure 2 As shown, an anammox reactor includes a tank body 100, a top cover 110, and a bottom head 120. Both ends of the tank body 100 are fixedly connected to the top cover 110 and the bottom head 120, respectively.

[0031] It also includes a degassing hood 200 , the degassing hood 200 is inverted in the middle of the tank body 100 , an anammox reaction zone is formed above the degassing hood 200 , and a nitrosation reaction zone is formed below the degassing hood 200 .

[0032] An anammox reaction device is arranged in the anammox reaction zone, and the anammox reaction device includes a fixed frame A211, a movable frame A212, and a limit groove A213. Both the fixed frame A211 and the limit slot A213 are fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com