Substation inspection robot system and inspection method

A technology for inspecting robots and substations, applied in the field of substation inspection, can solve problems such as increasing track laying and maintenance costs, monitoring device blind spots, and increasing substation safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

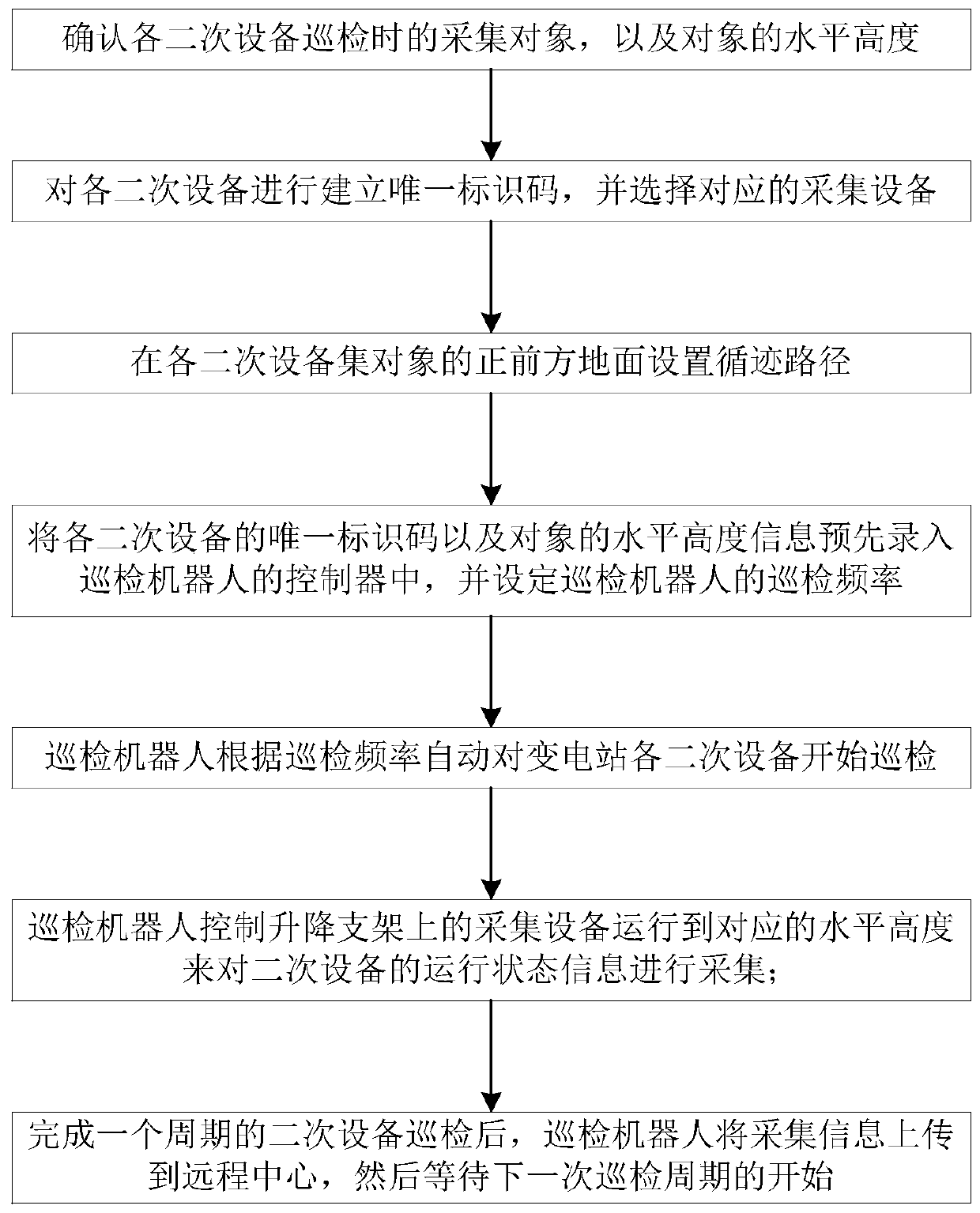

[0036] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

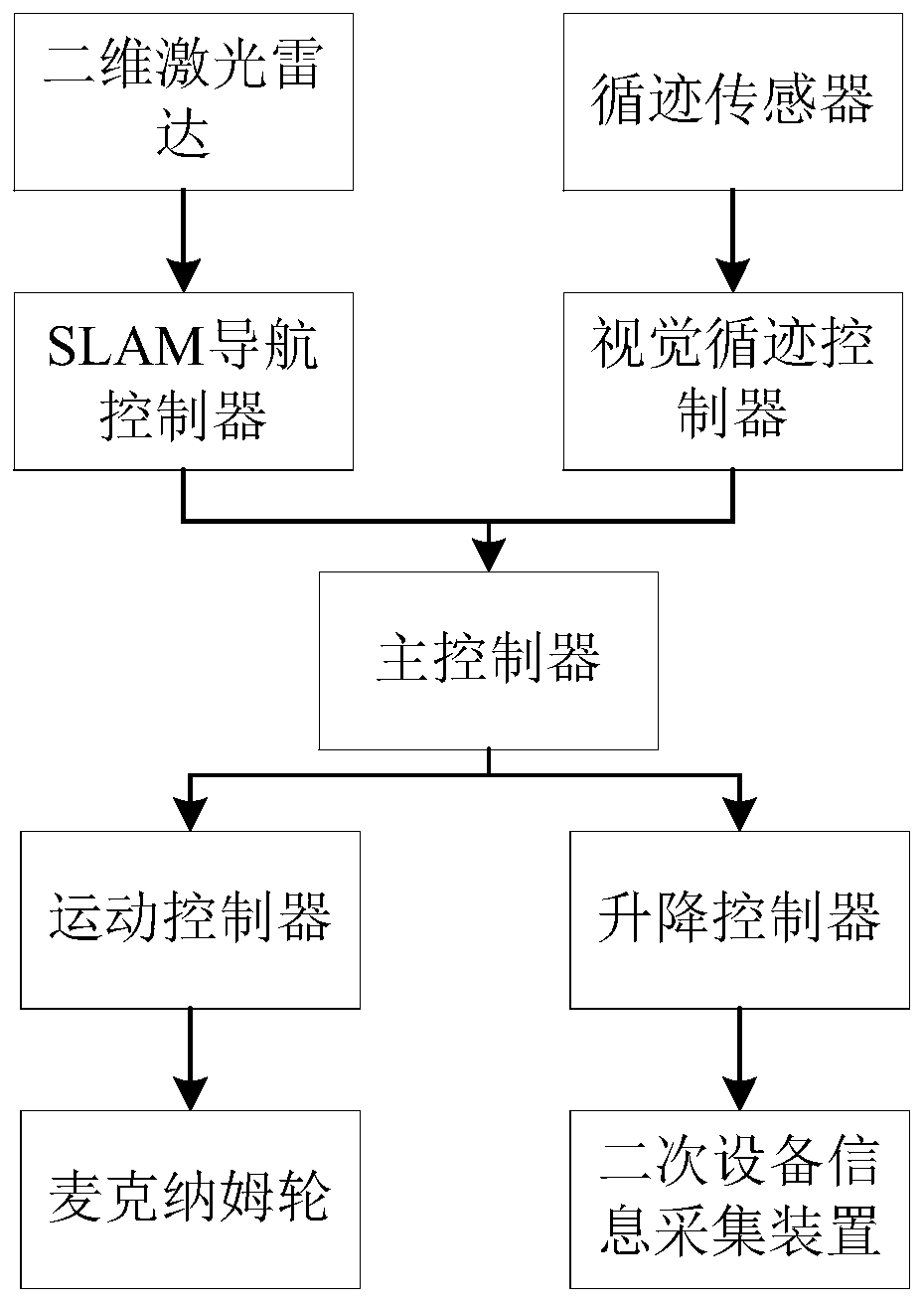

[0037] A substation inspection robot system includes a mobile mechanism, an information collection mechanism, and a control mechanism.

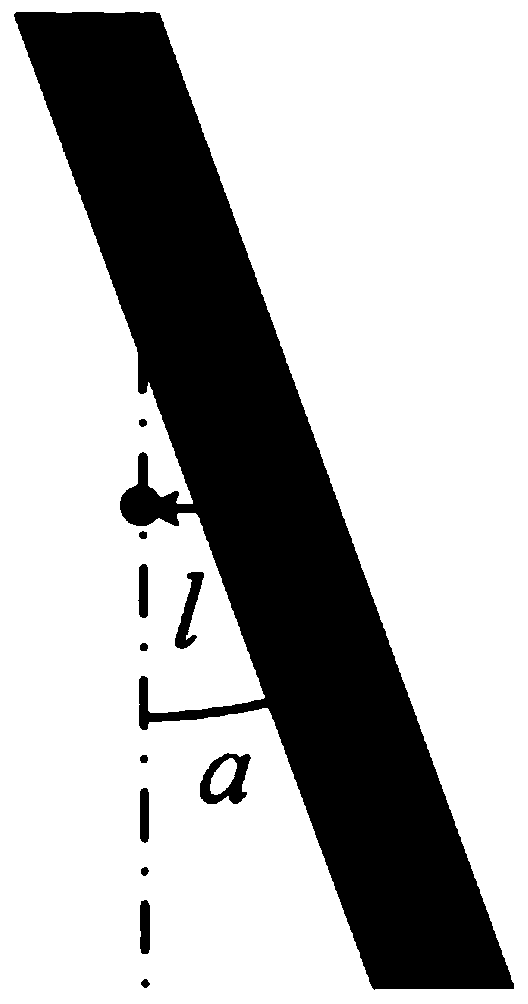

[0038] Wherein, the moving mechanism includes a moving platform at the bottom, and the moving platform includes four mecanum wheels symmetrically arranged, and the four mecanum wheels are separately driven by motors. The information collection mechanism includes a lifting support located on the mobile platform, and a secondary equipment information collection device installed on the top of the lifting support. The lifting bracket adopts two-stage synchronous belt and double slide rails, and is driven by a stepping motor. The control accuracy of the lifting bracket can reach 1mm. The secondary equipment information collection device is an optical camera and an infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com