Continuous vacuum coating production equipment and production method thereof

A technology of vacuum coating and production equipment, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of inability to achieve continuity, large-scale production, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

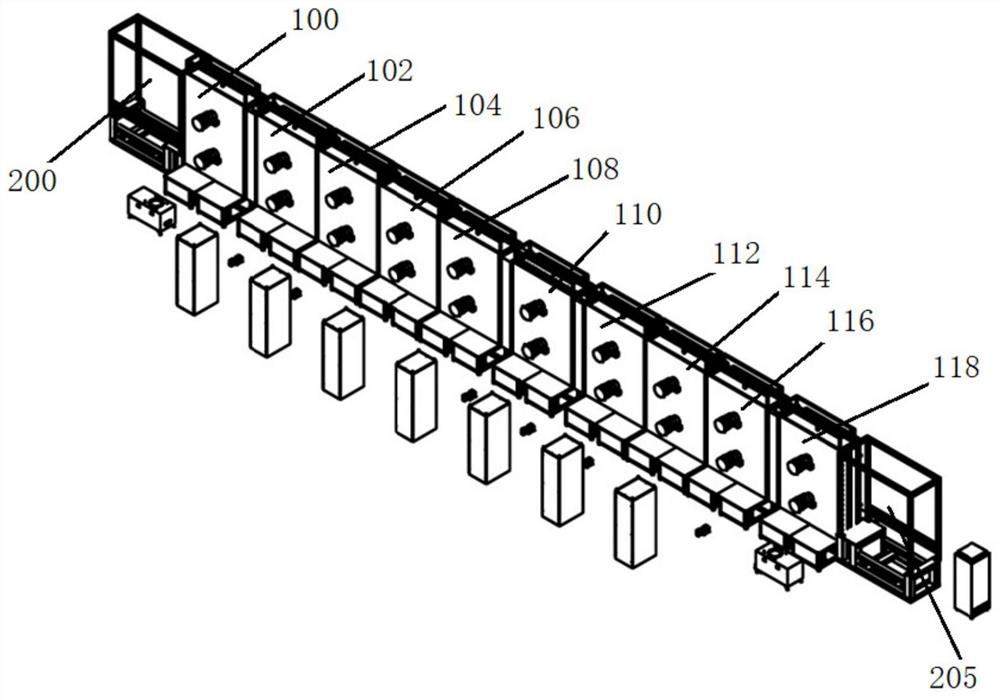

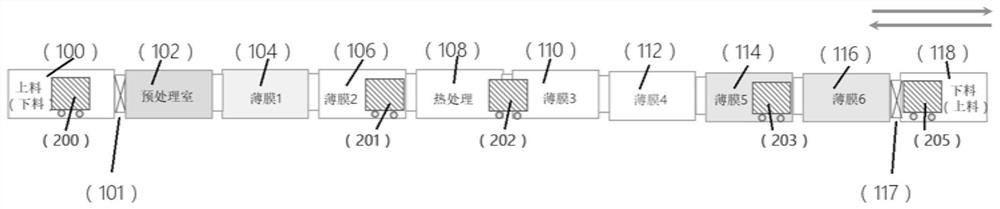

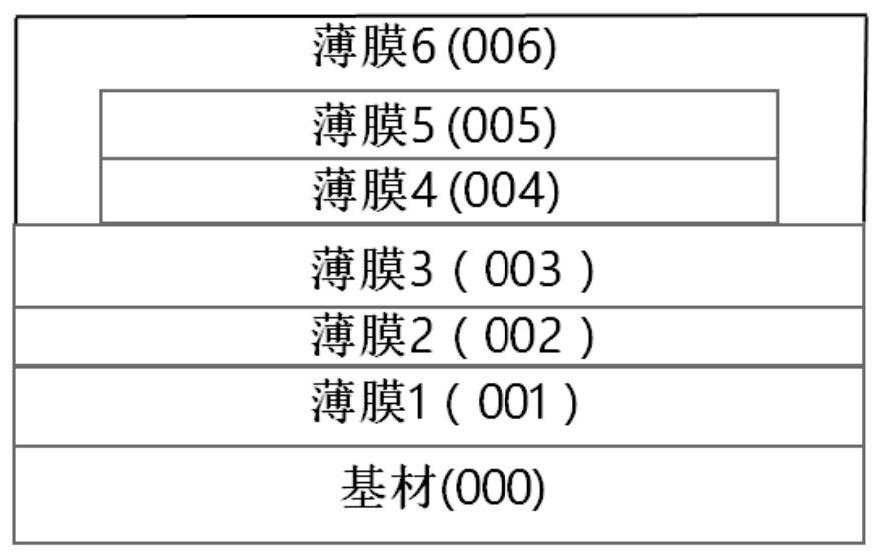

[0183] Embodiment 1: the manufacture of all-solid-state thin-film lithium battery, such as Figure 8 and Figure 9 Shown:

[0184] K1), select Ti (thickness 1mm) as base material, base material has flexibility, the background vacuum degree of vacuum system is 1 * 10 - 4 Pa, after the cleaned base material is fixed on the first movable frame (200), enter the high-vacuum vacuum feeding chamber (100) together, and enter the film 2 ( 106);

[0185] K2), in thin film 2 chamber (106), deposit thin film 2 as battery positive pole, positive pole is LiMn 2 o 4 , thickness 2000nm;

[0186]K3), in the heat treatment chamber (108), the substrate and the film are subjected to 800°C vacuum heat treatment;

[0187] K4), in film 3 chamber (110), deposit film 3, as battery electrolyte, electrolyte is lithium lanthanum zirconium oxygen (LLZO), thickness 3000nm;

[0188] K5), in thin film 4 chamber (112), deposit thin film 4, as battery negative pole, negative pole is Si, and thickness i...

Embodiment 2

[0193] Embodiment 2 Flexible lithium-free negative electrode type-manufacture of all-solid-state thin-film lithium battery, combined with Figure 10 and Figure 11 Shown:

[0194] J1), polyimide PI foil (thickness 10μm) is selected as the substrate, the substrate is ultra-thin and flexible, and the background vacuum of the vacuum system is 1×10 -4 Pa, after fixing the cleaned substrate on the first movable frame (200), enter the high-vacuum vacuum feeding chamber (100) together, and enter the pretreatment chamber through the first vacuum valve (101). (102);

[0195] J2), in the pretreatment chamber (102), use the ion source to perform ion bombardment cleaning and activation on the surface of the substrate;

[0196] J3), in the thin film 1 chamber (104), deposit thin film 1 to the base material, as battery anode current collector, material is aluminum, thickness 200nm;

[0197] J4), in thin film 2 chamber (106), deposit thin film 2, as battery positive electrode, positive e...

Embodiment 3

[0219] Example 3: Fabrication of Rigid Electrochromic Glass

[0220] combine Figure 12 and Figure 13 As shown, the steps of utilizing the above steps to manufacture electrochromic glass include the following:

[0221] (M1) Choose ordinary soda-lime ultra-thin glass (thickness 700 μm) as the substrate, and the background vacuum of the vacuum system is 1×10 -4 Pa, fix the cleaned substrate on the first movable frame (200), and enter the high-vacuum vacuum feeding chamber (100) together, and enter the film chamber 1 through the first vacuum valve (101). In the chamber (104), a thin film 1, ITO, is deposited on the substrate, with a thickness of 500nm, a heating temperature of 300°C, and a sheet resistance of 10 ohms / square;

[0222] (M2) in film 2 chamber (106), deposit film 2, WO 3 , as a glass color-changing layer with a thickness of 300nm; in the same chamber, deposit a Li film with a thickness of 50nm;

[0223] (M3) In the heat treatment chamber (108), the substrate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com