Super-precise turning method for free-form-surface prism

A curved prism and processing method technology, which is applied in the field of ultra-precision turning free-form prism processing, can solve the problems of reducing the processing efficiency of components, and achieve the effects of reducing production costs, strong adaptability, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

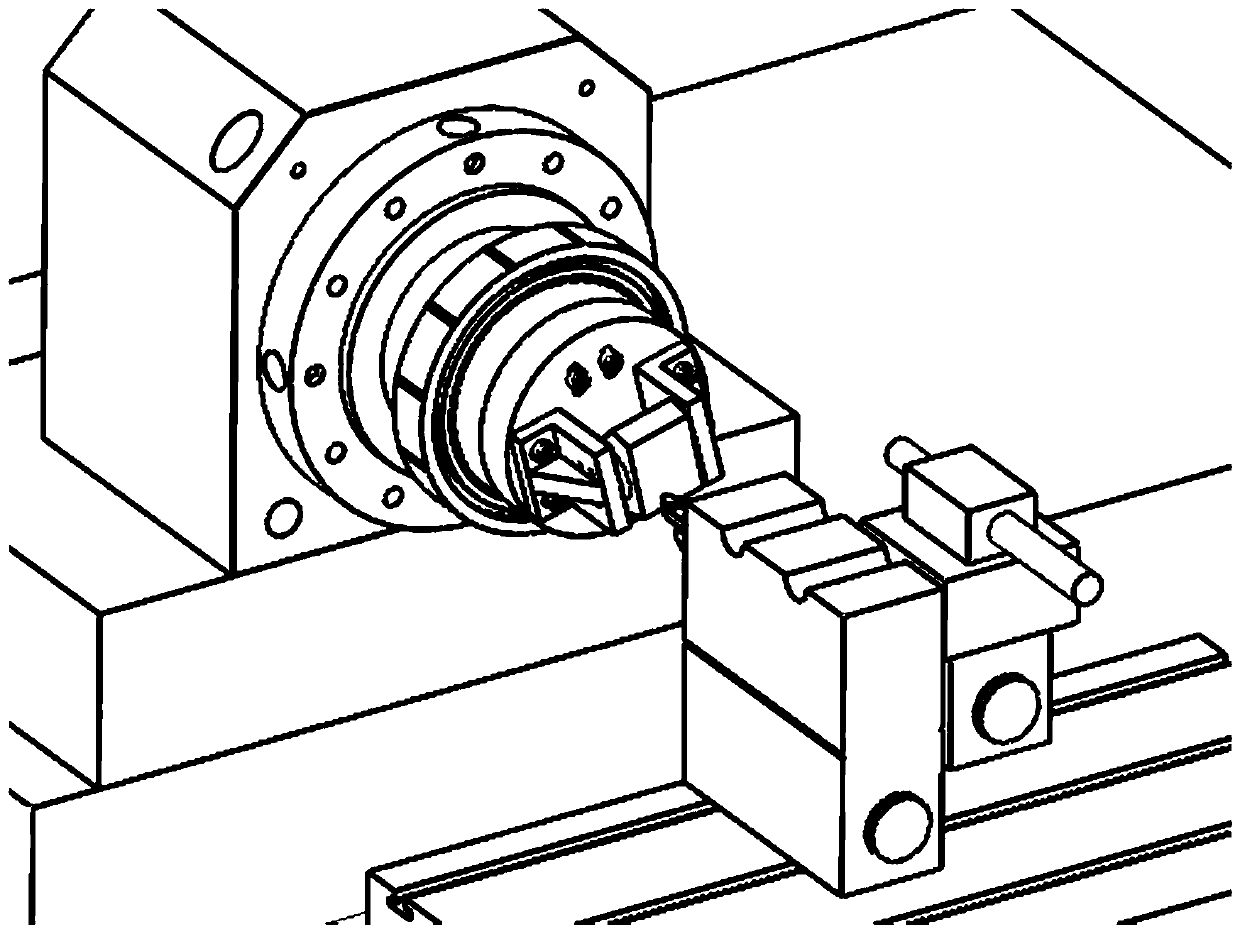

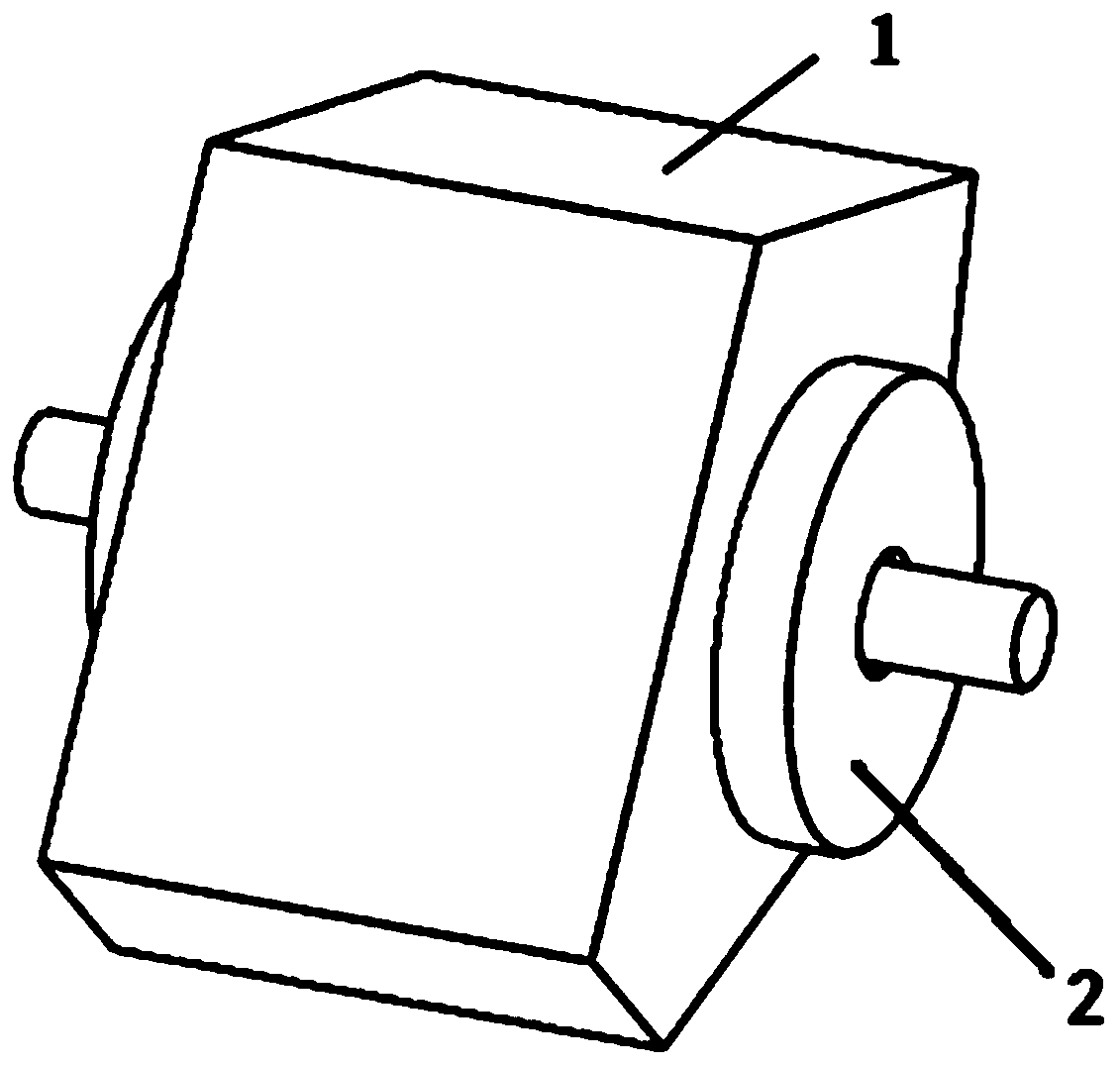

[0046] Such as figure 1 As shown, the present invention provides a method for processing ultra-precision turning free-form prisms, which realizes multiple internal reflection surfaces of ultra-precision turning free-form prisms 1 and utilizes optical probes for online positioning and detection to compensate for processing curved surface shape deviations, based on the X-axis A two-axis single-point diamond lathe with Z axis is designed to assist in the processing of free-form prisms. The thickness of the free-form prism 1 to be processed ranges from 30 to 70mm, and the material can be optical plastic and infrared materials.

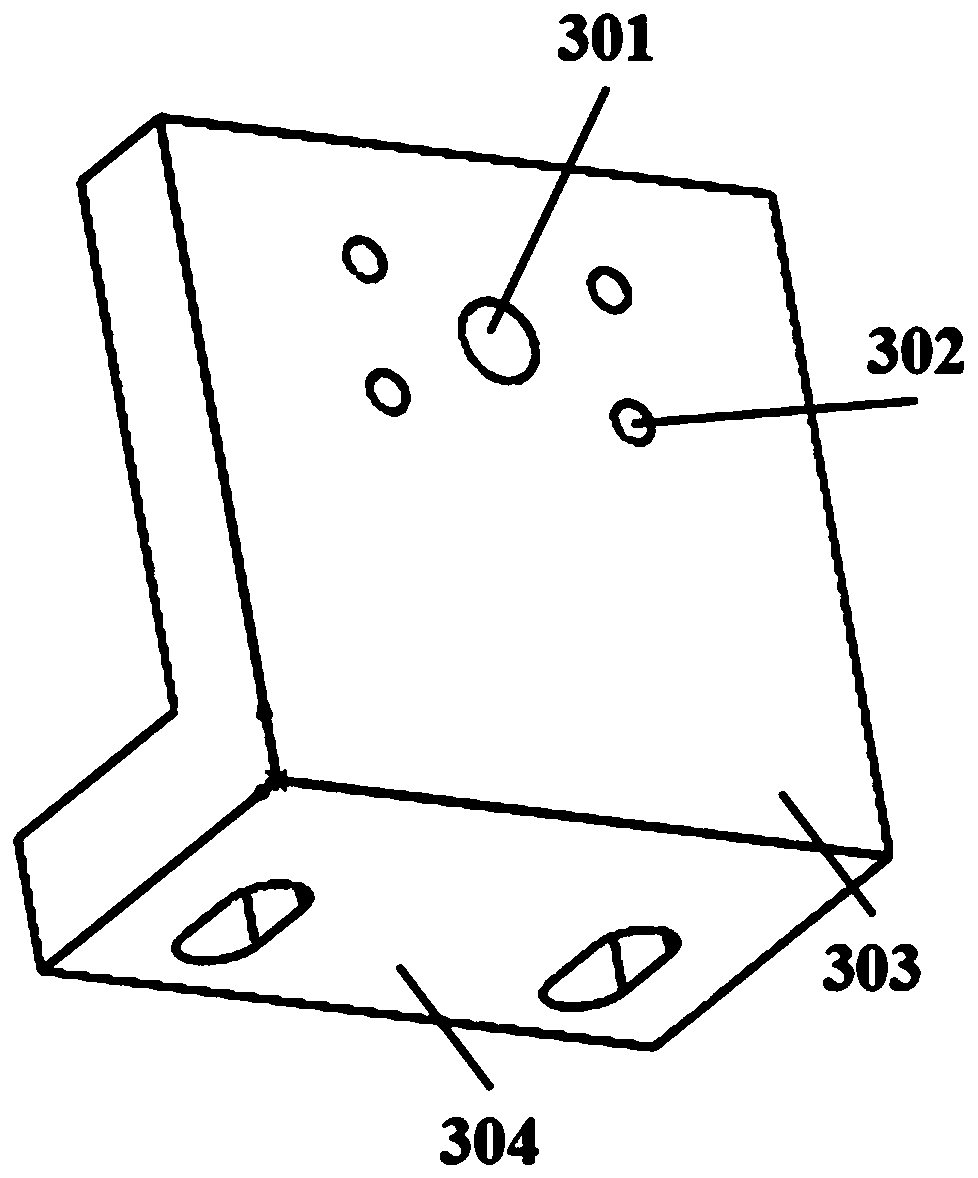

[0047]The present invention mainly designs the special adjustable tool assembly for clamping the free-form prism 1, and installs it on a common X-axis and Z-axis two-axis single-point diamond lathe for turning processing. Several parts of the free-form prism 1 are to be The processing surface can be switched and positioned online. The angle adjustment of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com