Motor vehicle front part

A technology for motor vehicles and vehicle speed, which is applied to vehicle components, machines/engines, mechanical equipment, etc., and can solve problems such as increasing vehicle air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

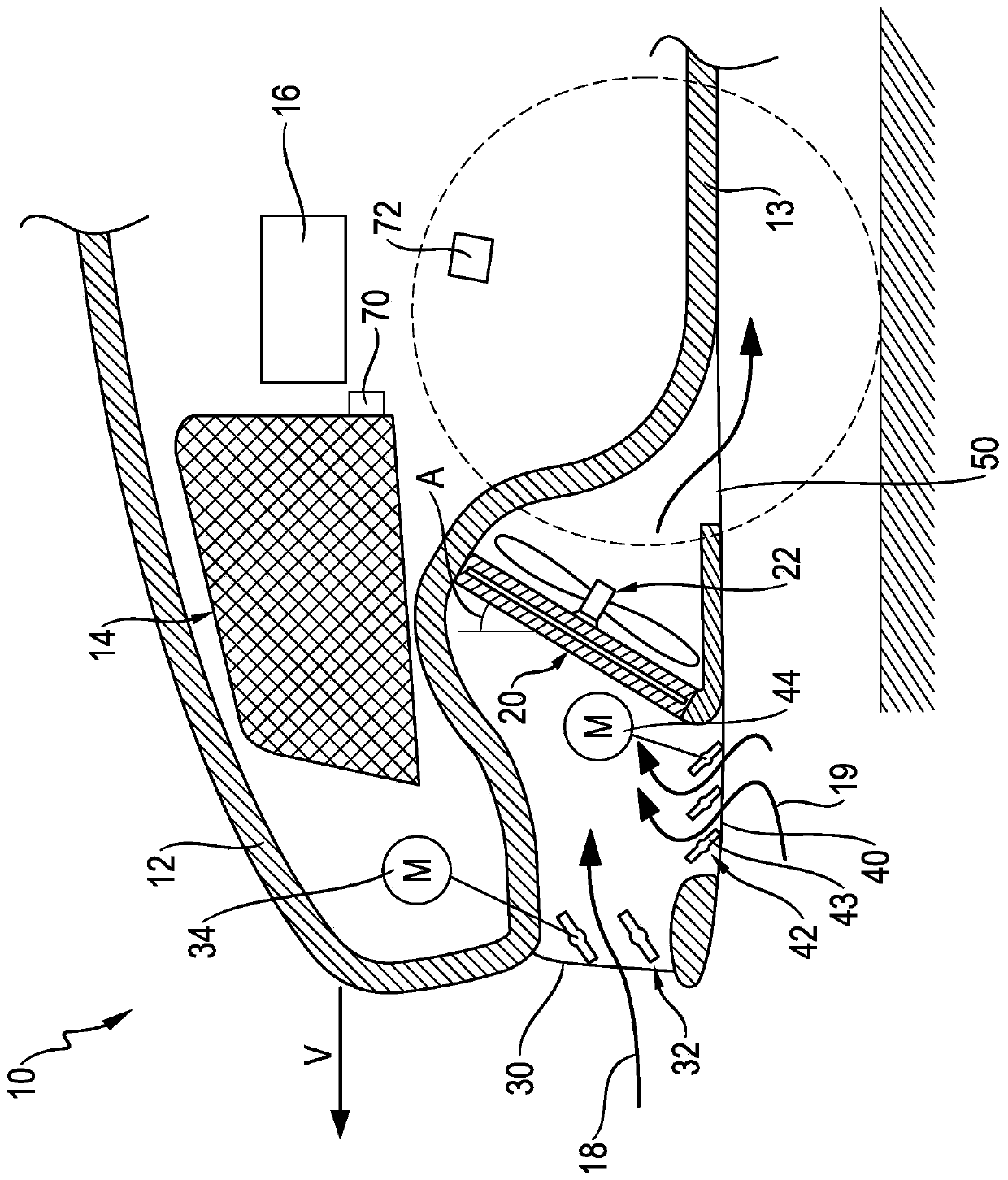

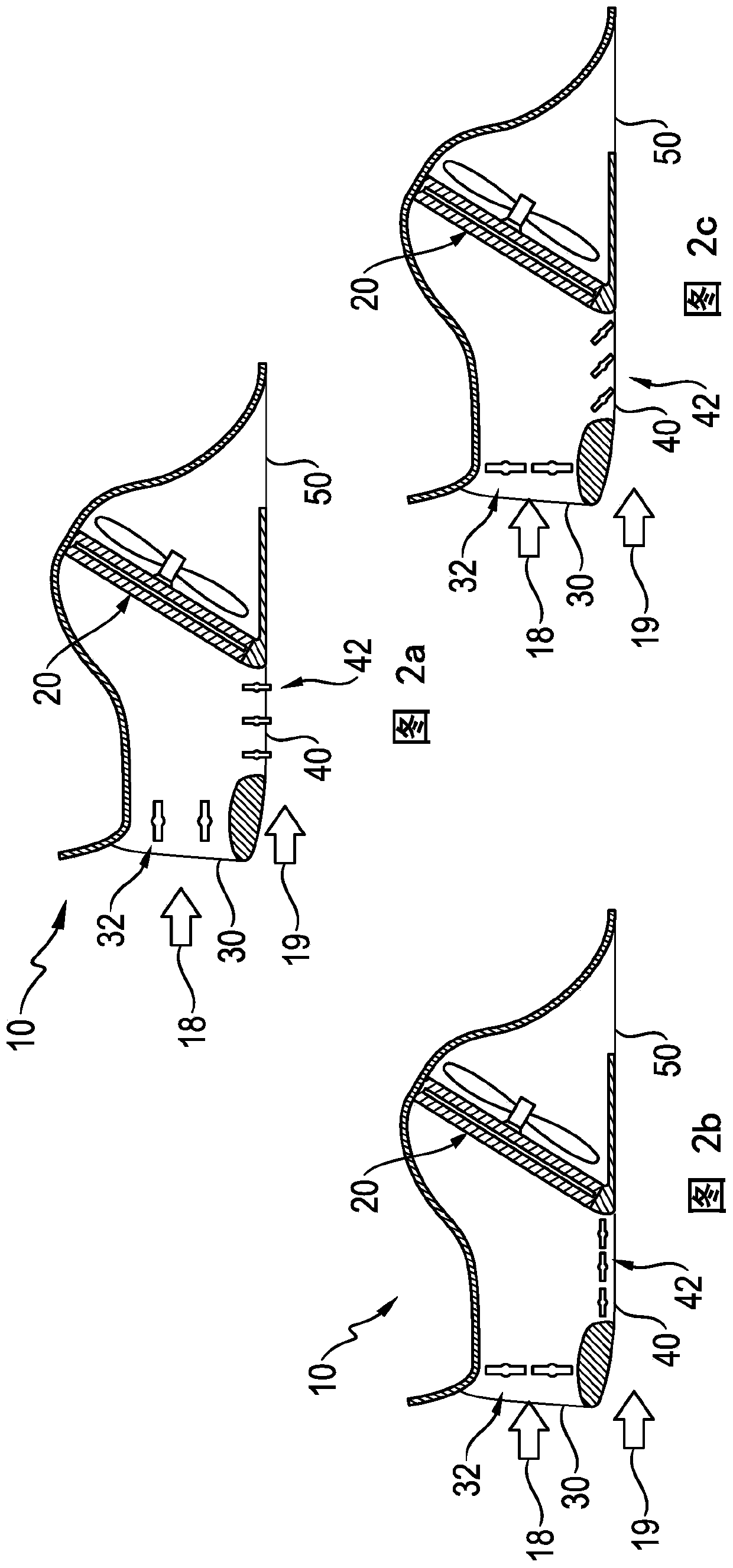

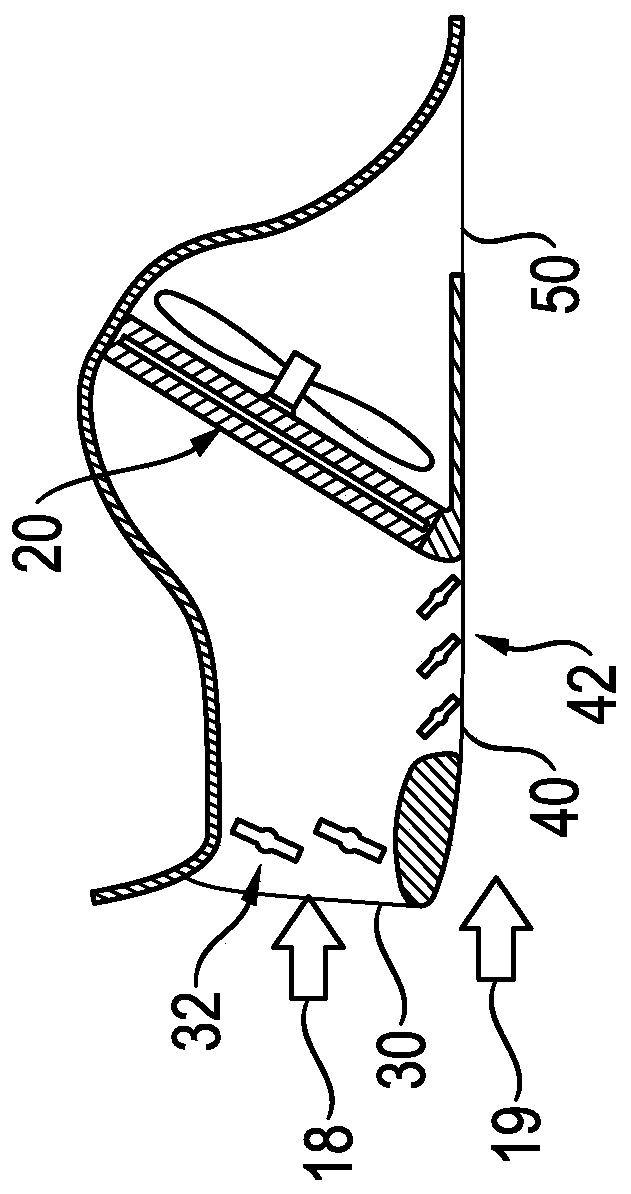

[0034] figure 1 A motor vehicle front 10 of a motor vehicle is schematically shown in longitudinal section. The outline of the front part 10 of the vehicle is defined by the vehicle body 12 within which is arranged a heat exchanger 20, a fan 22 arranged downstream of the heat exchanger 20 and driven by an electric drive motor, and a Complex cooling air installations for air supply and air discharge. The cooling air arrangement guides and controls the upper air path 18 and the lower air path 19 of the front, which can converge upstream of the heat exchanger 20 .

[0035] The cooling air device has an upper air intake opening 30 which is open substantially forward, in the opening plane of which an upper flap assembly 32 is arranged which is adjustable by a servo electric motor 34 . The upper air intake opening 30 has an upright, though not necessarily vertical, opening plane and is approximately and at least partially flush with the heat exchanger 20 in height.

[0036] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com