Supercavitation high-speed ship

A super-cavitation, high-speed technology, applied in the directions of ships, navigation aids, ship safety, etc., can solve problems such as the deterioration of ship static stability and ship dynamic stability, reduce frictional resistance, reduce wetted area, The effect of reducing the frictional resistance of the submerged body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

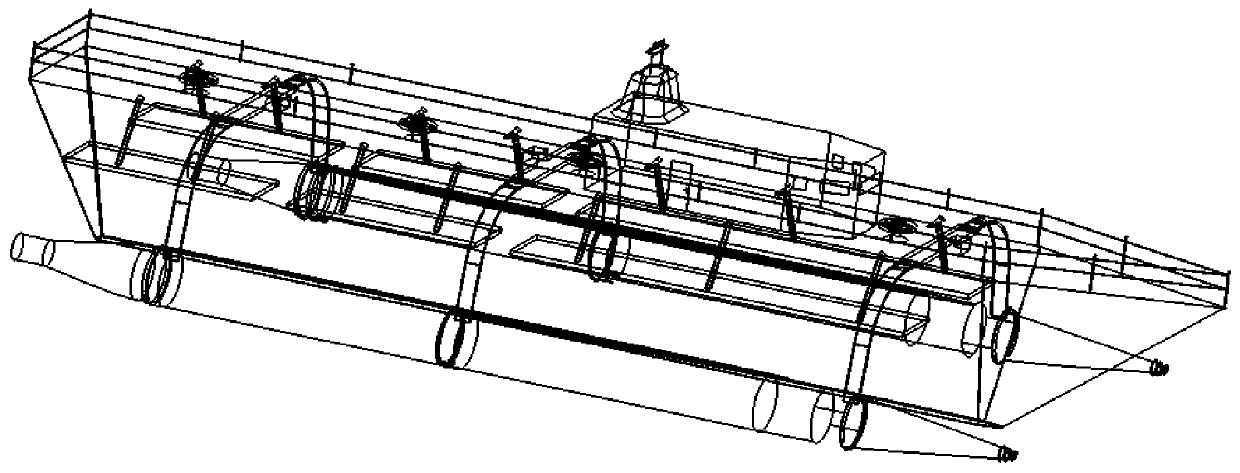

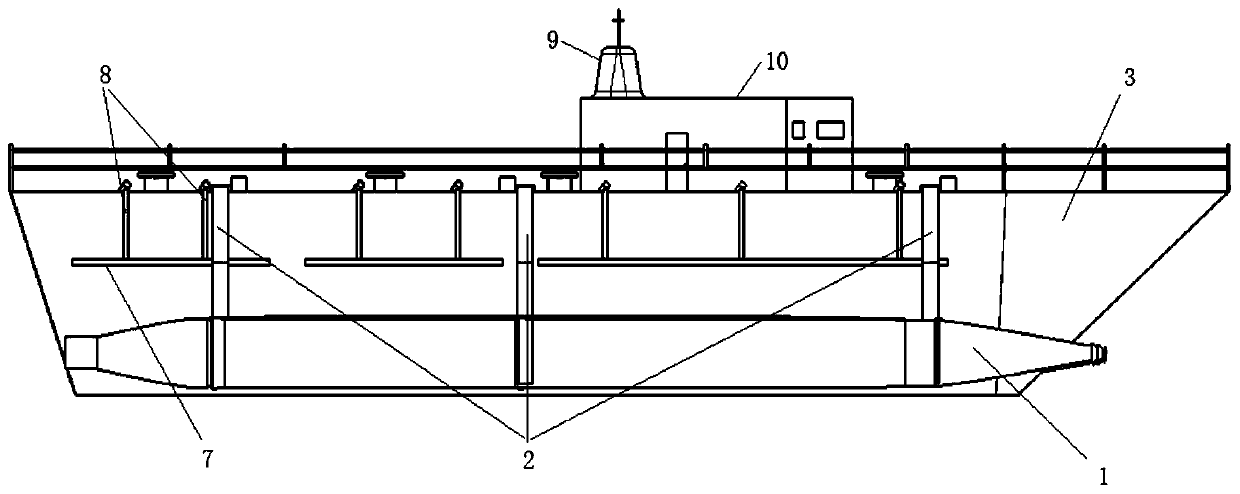

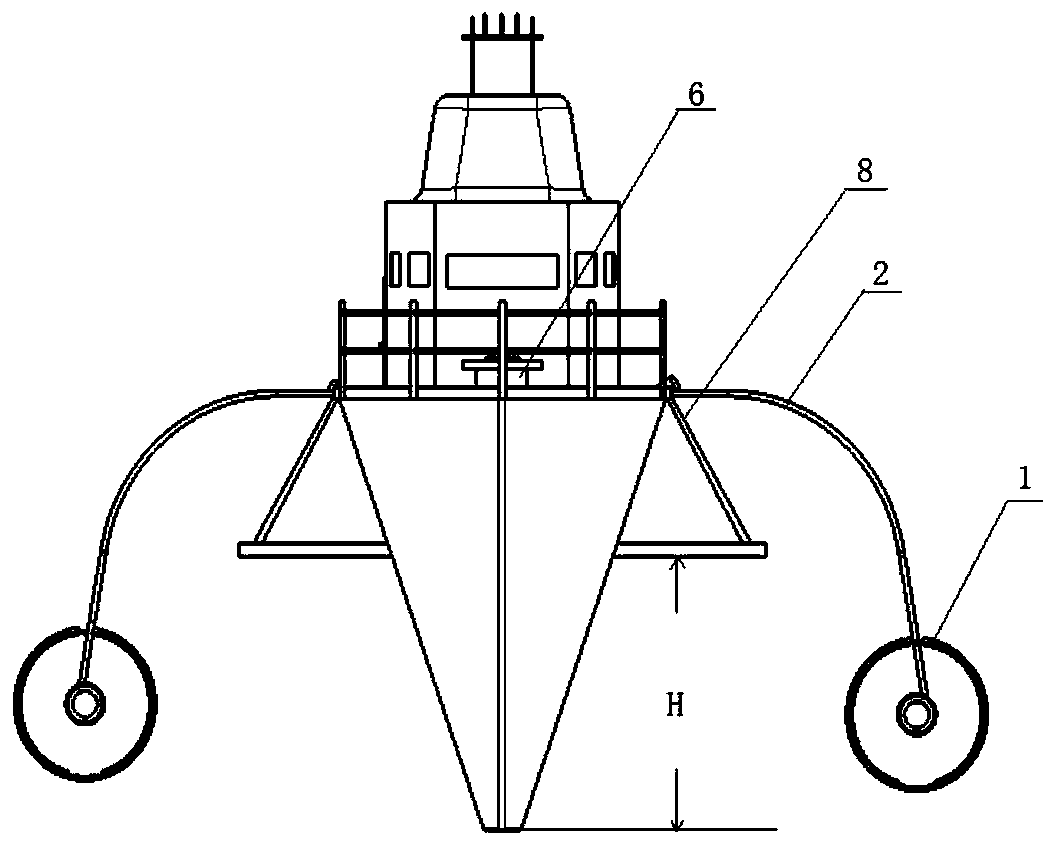

[0028] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0029] combine Figure 1 to Figure 8 , The present invention aims to provide a supercavitation high-speed ship that utilizes supercavitation technology, has a displacement of 2,000 tons, and can achieve high speed in water (about 50 knots) and sail stably. In order to minimize the external resistance caused by the submerged body itself, its slenderness ratio is generally designed to be between 11 and 21. The submersible body is composed of a three-segment axisymmetric revolving body with a front cone, a middle cylinder and a tail inverted cone. The specific size of the submerged body is determined by the relationship between the lengths of each part of the submersible body, the general rules of the submersible body design and the slenderness ratio of the submersible body.

[0030] A disc cavitation is arranged on the head of the subme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com