Pearlescent paint, pearlescent coating, panel and household appliance

A pearlescent pigment and pearlescent technology, applied in the coating and other directions, can solve the problem that the coating cannot meet the fineness and weather resistance at the same time, and achieve the effect of fine pearlescent effect, fast drying and accelerated curing speed.

Inactive Publication Date: 2019-12-27

GREE ELECTRIC APPLIANCES INC

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The main purpose of the present invention is to provide a pearlescent coating, a pearlescent coating, a panel and home appliances, so as to solve the problem that the coatings in the prior art cannot meet the requirements of fineness and weather resistance at the same time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

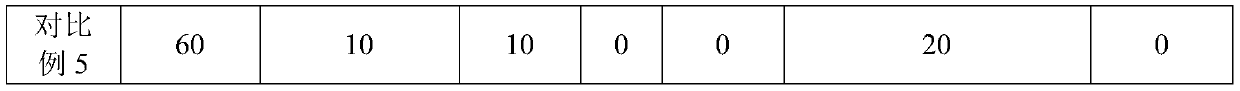

Embodiment 6

[0037]The difference from Example 1 is that the pearlescent pigment is a mixture of 70% mica and 30% titanium dioxide.

Embodiment 7

[0039] The difference from Example 1 is that the pearlescent pigment is a mixture of 80% mica and 20% titanium dioxide.

Embodiment 8

[0041] The difference from Example 1 is that the pearlescent pigment is a mixture of 50% mica and 50% titanium dioxide.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

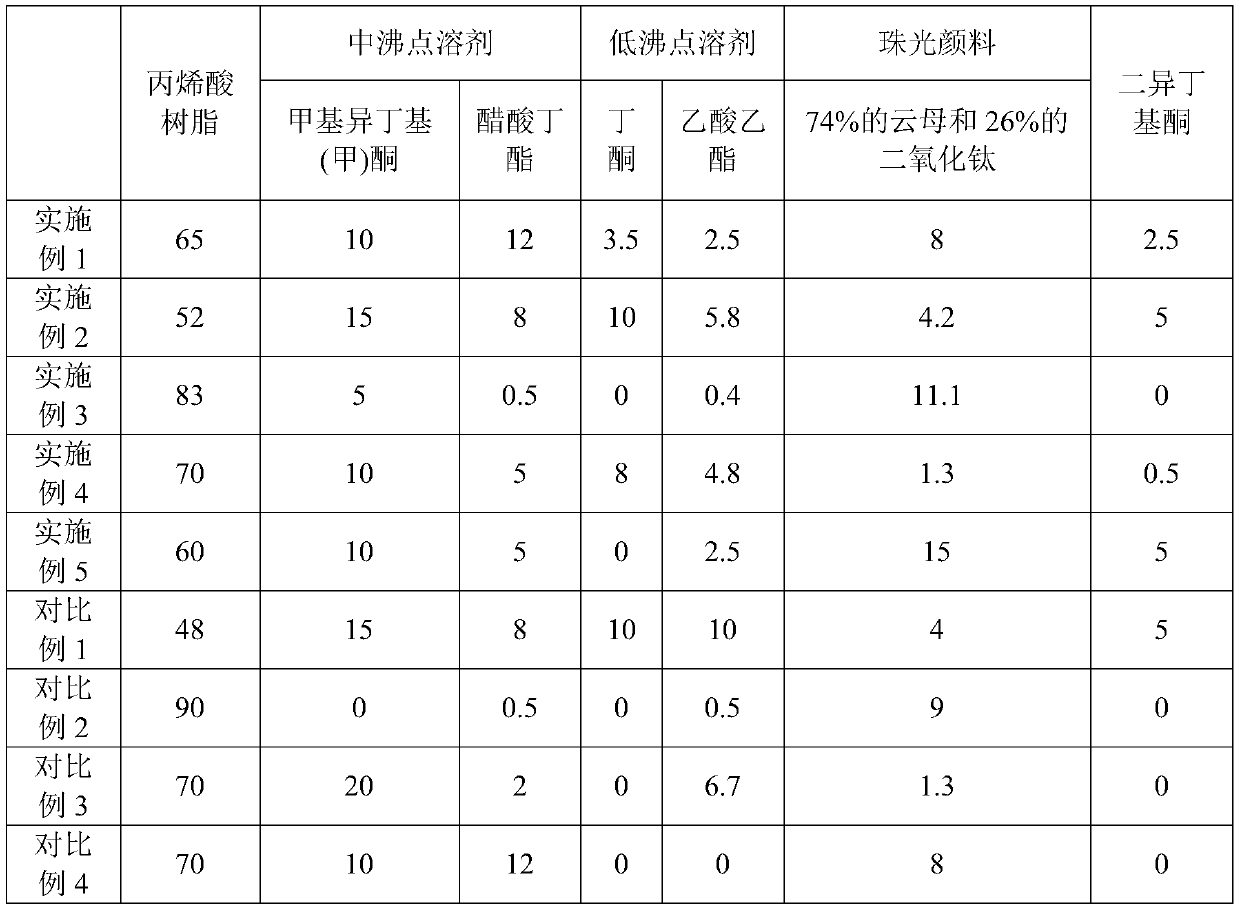

The invention provides pearlescent paint, a pearlescent coating, a panel and a household appliance. The pearlescent paint comprises comprises the following components in parts by weight: 52-83 partsof acrylic resin, 5-23 parts of a medium-boiling-point solvent, 0.4-16 parts of a low-boiling-point solvent and 1.3-15 parts of pearlescent pigment, the medium-boiling-point solvent comprises 5-15 parts of a medium-boiling-point ketone solvent and 0.5-12 parts of a medium-boiling-point ester solvent, and the low-boiling-point solvent comprises 0.4-16 parts of a low-boiling-point ester solvent. Themedium-boiling-point solvent is matched with the low-boiling-point solvent, so that the sufficient dispersity of the acrylic resin and the pearlescent pigment and the uniformity and smoothness of theformed pearlescent coating are ensured; and the curing speed is properly increased, so that the fineness of the formed pearlescent coating is improved, the defects of pinholes and the like caused bytoo high curing speed are avoided, the weather resistance is improved, and the particle size of the pearlescent pigment is further reduced, so that a fine pearlescent effect is achieved.

Description

technical field [0001] The invention relates to the technical field of coatings, in particular to a pearlescent coating, a pearlescent coating, a panel and home appliances. Background technique [0002] With the diversified needs of the market, paints with various effects appear in the spraying industry, including but not limited to metallic texture, rubber feel, matte effect, pearlescent effect, etc. Spraying with the existing paint in the industry, in the case of meeting the weather resistance performance, it is necessary to control the particle size of the pearl powder to be more than 15 μm, which cannot achieve the delicate pearl effect, resulting in rough appearance and texture. However, if fine pearl powder paint is used, the weather resistance of the product will be poor if the fineness is satisfied. Contents of the invention [0003] The main purpose of the present invention is to provide a pearlescent coating, a pearlescent coating, a panel and a home appliance, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D133/04C09D7/20C09D7/61

CPCC08K2003/2241C09D7/20C09D7/61C09D133/04C08K3/34C08K3/22

Inventor 胡玮周绍波谭兵王文斌张玮

Owner GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com