A kind of floor coating system and construction method thereof

A technology of coating system and construction method, which is applied to coatings, polyurea/polyurethane coatings, floors, etc., can solve the problem of inability to meet the needs of large bus parking lots, insufficient floor wear resistance, and high rigidity of the coating system and other problems, to achieve the effect of improving gloss and color retention, maintaining integrity and resistance to chalking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

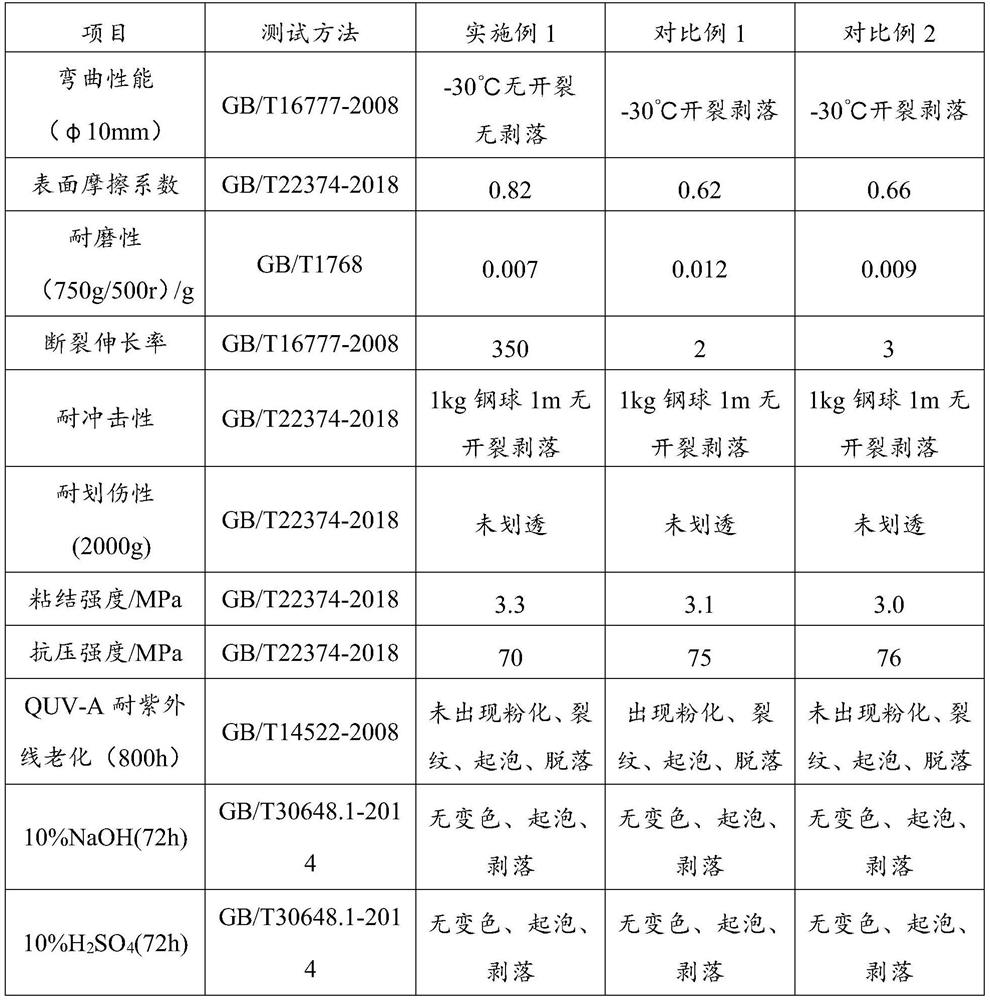

Examples

Embodiment 1

[0047] The construction of the floor coating system on the ground of the bus parking lot includes the following steps in order to obtain the floor coating system:

[0048] Base surface treatment: Shot blasting the ground to remove laitance, empty shells, old coatings and coarse impurities on the base surface. The mass ratio of 2:1 is mixed, and the blades of the blasting machine are ductile iron blades;

[0049] Primer: at 0.22kg / m 2 The amount of construction roller coating Will solvent-free epoxy primer ACE-1001, to achieve the surface film formation, uniform without omission; at the same time sprinkle 50 ~ 60 mesh quartz sand;

[0050] Base surface crack treatment: ① For cracks with a width less than 5mm, cut the cracks into V-shaped grooves with a depth of 20mm and a width of 20mm, and fill them with Will polyurea elastic coating VSF-MF; ② For cracks or potholes with a width greater than 5mm, Use Will polyurea elastic coating VSF-MF to mix 0.5 times 30-40 mesh quartz san...

Embodiment 2

[0057] The construction of the floor coating system on the ground of the bus parking lot includes the following steps in order to obtain the floor coating system:

[0058] Base surface treatment: Shot blasting the ground to remove laitance, empty shells, old coatings and coarse impurities on the base surface. The mass ratio of 2:1 is mixed, and the blades of the blasting machine are ductile iron blades;

[0059] Primer: at 0.24kg / m 2 The amount of construction roller coating Will solvent-free epoxy primer ACE-1001, to achieve the surface film formation, uniform without omission; at the same time sprinkle 50 ~ 60 mesh quartz sand;

[0060] Base surface crack treatment: ① For cracks with a width less than 5mm, cut the cracks into V-shaped grooves with a depth of 20mm and a width of 20mm, and fill them with Will polyurea elastic coating VSF-MF; ② For cracks or potholes with a width greater than 5mm, Use Will polyurea elastic coating VSF-MF to mix 0.5 times 30-40 mesh quartz san...

Embodiment 3

[0067] The construction of the floor coating system on the ground of the bus parking lot includes the following steps in order to obtain the floor coating system:

[0068] Base surface treatment: Shot blasting the ground to remove laitance, empty shells, old coatings and coarse impurities on the base surface. The mass ratio of 2:1 is mixed, and the blades of the blasting machine are ductile iron blades;

[0069] Primer: at 0.25kg / m 2 The amount of construction roller coating Will solvent-free epoxy primer ACE-1001, to achieve the surface film formation, uniform without omission; at the same time sprinkle 50 ~ 60 mesh quartz sand;

[0070] Base surface crack treatment: ① For cracks with a width less than 5mm, cut the cracks into V-shaped grooves with a depth of 20mm and a width of 20mm, and fill them with Will polyurea elastic coating VSF-MF; ② For cracks or potholes with a width greater than 5mm, Use Will polyurea elastic coating VSF-MF to mix 0.5 times 30-40 mesh quartz san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com