Patents

Literature

38results about How to "Improve gloss and color retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkyd paint for ship cabin and its production process

InactiveCN1810902AImprove temperature resistanceImprove moisture and water resistanceAntifouling/underwater paintsPaints with biocidesSolventResin modified

The present invention discloses one kind of paint for steel structure surface of ship and its production process. The paint has the main components including organic silicon resin modified alkyd resin, phenolic resin modified alkyd resin, pigment, nanometer zinc oxide, superfine aluminum hydroxide, superfine barium sulfate, nanometer silica, paint drier, No. 200 solvent gasoline and methyl ethyl ketoxime. The production process includes dispersing all the materials except paint drier and methyl ethyl ketoxime in a cylinder for 15 min, sand grinding to fineness superior to 40 microns, regulating with resin and paint drier to acid value not greater than 11 mgKOH / g and viscosity of 200-400 sec at 25 deg.c, filtering, packing while adding methyl ethyl ketoxime. The present invention solves the problem of paint film to release fume and toxic matter and has high safety performance and heat resistance.

Owner:梁新方

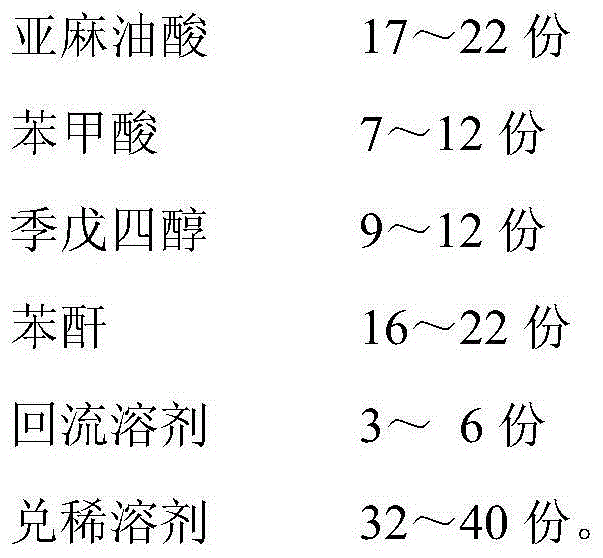

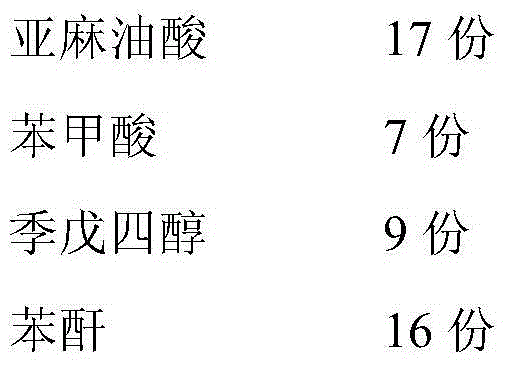

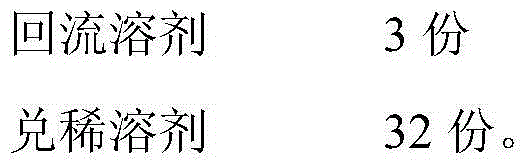

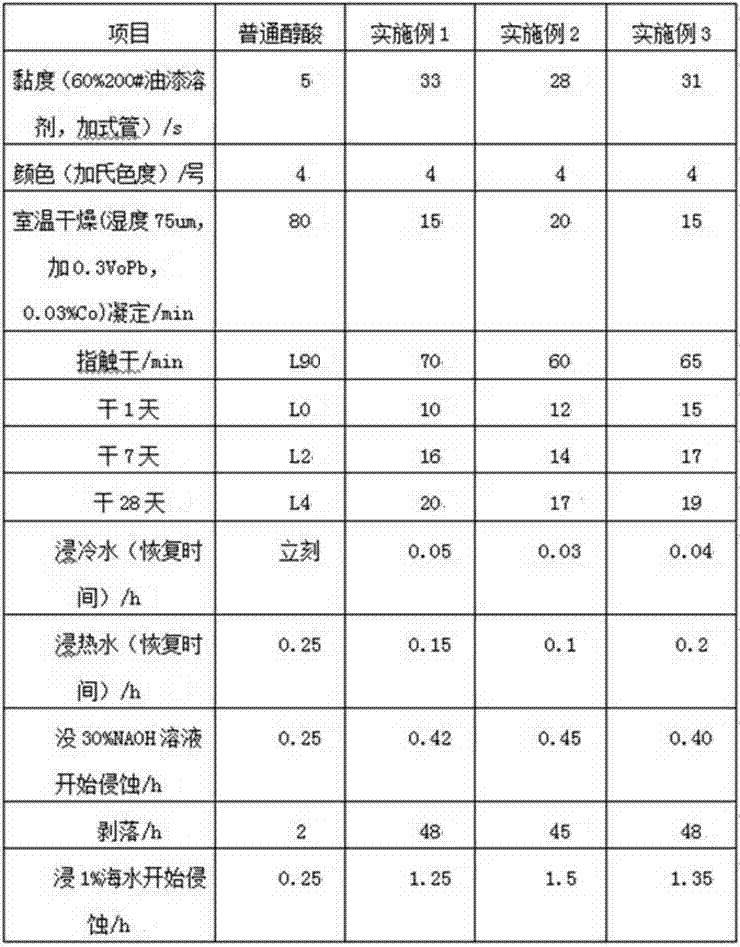

Quick-dried alkyd resin and preparation method thereof

InactiveCN104448269AShorten the construction periodEasy to dryPolyester coatingsBenzoic acidPentaerythritol

The invention discloses quick-dried alkyd resin and a preparation method thereof. The quick-dried alkyd resin is prepared from the following components in parts by weight: 17-22 parts of linoleic acid, 7-12 parts of benzoic acid, 9-12 parts of pentaerythritol, 16-22 parts of phthalic anhydride, 3-6 parts of a backflow solvent and 32-40 parts of a diluted solvent. By adopting the alkyd resin disclosed by the invention, the hard drying time of conventional alkyd resin is shortened to be 8 hours from the conventional 24 hours, so that the construction period of users is shortened. Compared with paint prepared from conventional alkyd resin, the quick-dried alkyd resin is relatively rapid to dry, relatively better in hardness, relatively excellent in mechanical property and relatively high in light and color retention property.

Owner:WUXI HUHUANG PAINT

Vacuum gold-plated primer

InactiveCN104559746ARaw materials are easy to getLow costPolyurea/polyurethane coatingsSolventSkin agent

The invention discloses a vacuum gold-plated primer which comprises the following components in percentage by mass: 55 to 60 percent of alcohol acid modified urethane oil, 20 to 25 percent of rosin modified phenolic resin, 1 to 2 percent of a dryer, 1 to 2 percent of an anti-skinning agent, 0.3 to 0.4 percent of organic modified nano SiO2, 0.2 to 0.3 percent of organic modified nano graphene and 11 to 22 percent of No.200 solvent oil. The alcohol acid modified urethane oil is prepared from the following components in percentage by mass: 5 to 10 percent of linseed oil, 1 to 5 percent of soybean oil, 10 to 15 percent of stillingia oil, 5 to 10 percent of pentaerythritol, 15 to 20 percent of toluene diisocynate and 40 to 64 percent of No.200 solvent oil. The vacuum gold-plated primer disclosed by the invention has the advantages of low cost, good adhesive force, high hardness, excellent heat resistance, controllable curing time, bright and full surface, high convenience in construction and the like and is suitable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Alkyd resin for floor paint

The alkyd resin with high solid content and low viscosity and used for floor paint is prepared with lauric acid, benzoic acid, adipic acid, trimethylol propane, neopentadiol, phthalic anhydride and other material. The alkyd resin is compounded with tolylene diisocyanate affixture or tripolymer. The coating has high adhesion, high hardness, high wear resistance, high shock resistance, good weather resistance, less volatile and other advantages, and the paint may be sprayed or brushed.

Owner:GUANGDONG BADESE CHEM

Water-soluble acrylic alkyd resin and preparation method thereof

InactiveCN103772621AIncreased durabilityGood weather resistanceCoatings(Hydroxyethyl)methacrylatePolymer science

The invention discloses water-soluble acrylic alkyd resin and a preparation method thereof. The water-soluble acrylic alkyd resin is prepared from the following raw materials in percentage by weight: 40-50% of flaxseed oil, 15-20% of trimethylolpropane, 3-6% of pentaerythritol, 2-5% of phthalic acid, 3-6% of m-phthalic acid, 8-12% of trimellitic anhydride, 30-40% of butyl acrylate, 4-8% of glycidol methacrylate, 3-6% of acrylic acid, 20-25% of hydroxyethyl methacrylate, 10-15% of styrene, 20-30% of butyl glycol ether, 5-10% of xylene and 2-4% of composite initiator. The water-soluble acrylic alkyd resin disclosed by the invention has the advantages of excellent durability, weatherability, wettability, solvent resistance, corrosion resistance, flexibility, gloss and color retention, quick drying, high hardness, storage stability and the like, and the use performance is improved on the basis that the defects of poor storage stability, poor wettability and the like of the ordinary alkyd resin are overcome, so that the application field of the water-soluble acrylic alkyd resin is enlarged.

Owner:FUSHUN JIUFENG SYNTHETIC RESIN MFG CO LTD

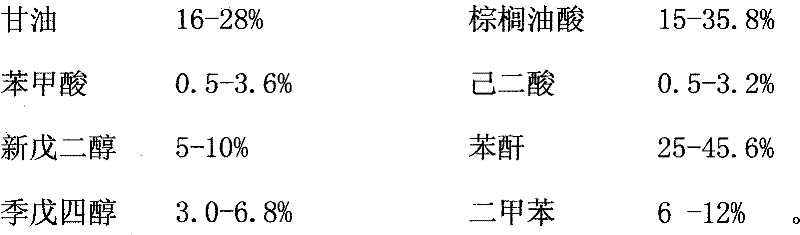

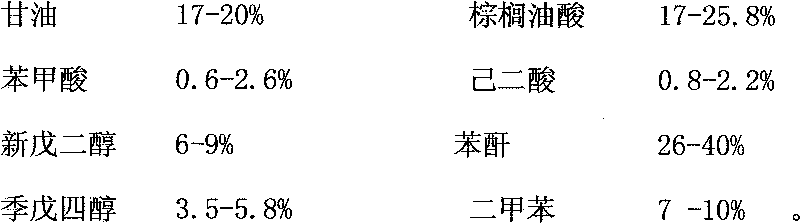

Light alkyd resin for interior decoration and furniture coating and preparation method thereof

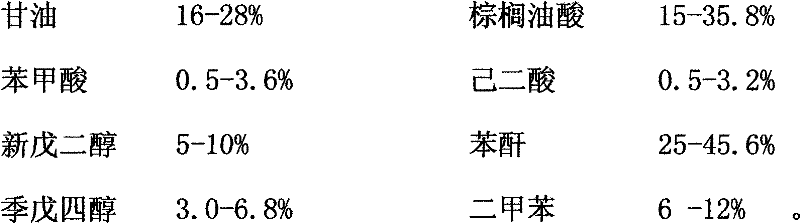

The invention discloses light alkyd resin for interior decoration and furniture coating, which is formed by the following raw materials: glycerol, palmitoleic acid, benzoic acid, hexanedioic acid, neopentyl glycol, phthalic anhydride, tetramethylolmethane and dimethylbenzene; the preparation method comprises the following steps: a. the palmitoleic acid, the benzoic acid, the hexanedioic acid, the glycerin, the neopentyl glycol, the phthalic anhydride, the tetramethylolmethane and the dimethylbenzene are thrown in a reactor one time, are heated and are stirred; b. carbon dioxide gas flows in the reactor to protect temperature rise, when the temperature is raised to 130-180 DEG C and kept for 1-3 hours, at the moment, the dimethylbenzene flows back, and then the temperature is raised to 200 plus / minus 5 DEG C at the temperature raising speed with 8-12 DEG C per hour, and then the temperature is kept for 4-8 hours; c. a sample is taken out in the step b for measuring viscosity, when the viscosity reaches desired value, the temperature is cooled to 130-180 DEG C, so as to obtain the modified alkyd resin; d. the alkyd resin in the step c is transferred to another reactor, and then 2.5-8.5 percent of dimethylbenzene is added, the mixture is mixed uniformly to obtain the water-white alkyd resin liquid.

Owner:四川巴德士新材料有限公司

Bottom surface universal type alkyd antirust paint and preparation method thereof

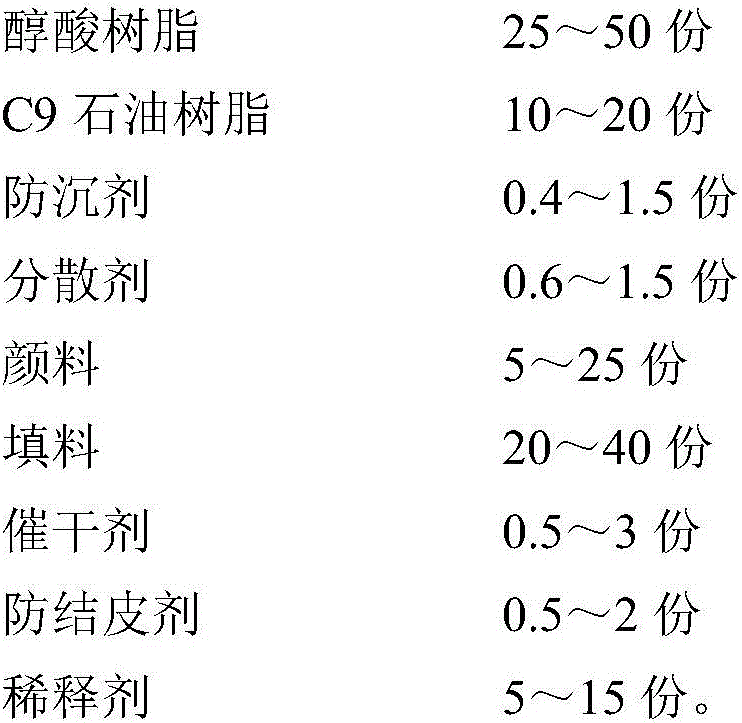

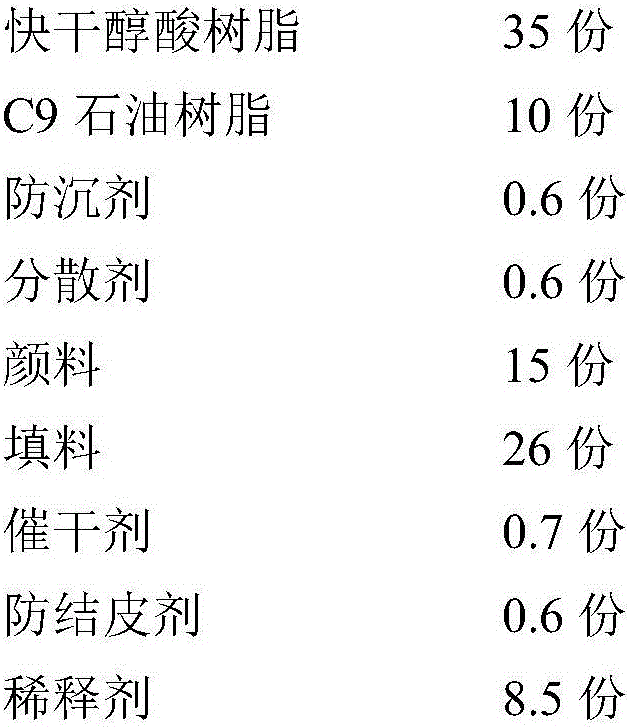

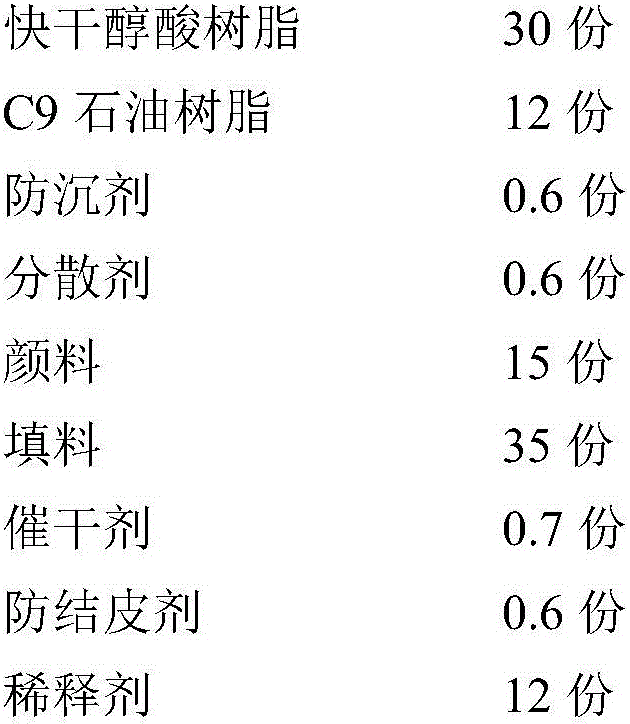

The invention discloses bottom surface universal type alkyd antirust paint. The bottom surface universal type alkyd antirust paint is prepared from the following components in parts by weight: 25 to 50 parts of alkyd resin, 10 to 20 parts of C9 petroleum resin, 0.4 to 1.5 parts of an anti-settling agent, 0.6 to 1.5 parts of a dispersant, 5 to 25 parts of pigment, 20 to 40 parts of filler, 0.5 to 3 parts of a drier, 0.5 to 2 parts of an anti-skinning agent and 5 to 15 parts of a diluent. The invention further discloses a preparation method of the bottom surface universal type alkyd antirust paint; the preparation method comprises the main steps of adding the raw materials in sequence and uniformly mixing. The bottom surface universal type alkyd antirust paint provided by the invention can be used as a primer and can also be used as finish paint and can dry rapidly; hard dry time is reduced to 4 hours from original 12 hours, and a construction period can be shortened; the hardness, mechanical property and brightness-keeping and color-keeping performance are all greatly improved. The preparation method is simple to operate and is suitable for large-scale industrial production.

Owner:WUXI HUHUANG PAINT

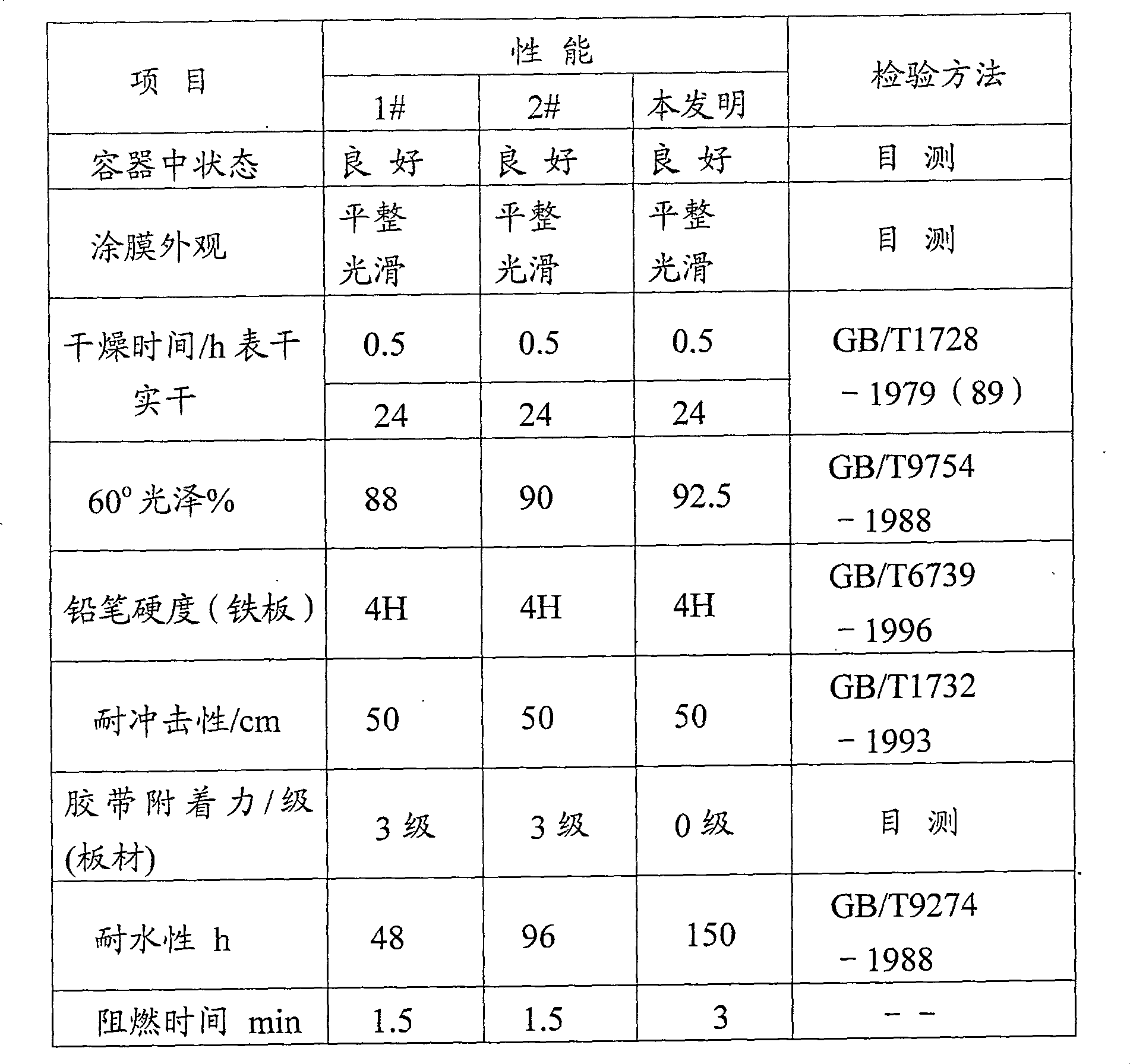

Paint special for high density plate material and its preparation method

InactiveCN1903955AGood weather resistanceImprove water resistanceLiquid surface applicatorsCoatingsCyclohexanoneAdjuvant

The present invention relates to a special-purpose coating for high-density plate material and its preparation method. It is made up by mixing high-molecular film-forming material, pigment, adjuvant and solvent. It is characterized by that the main component of high-molecular film-forming material of said coating is formed from (by weight portion) 40-50 portions of butyl methacrylate (BMA), 30-40 portions of styrene (ST), 10-20 portions of hydroxyethyl methacrylate (HEMA), 0.1-0.5 portion of methyl acrylic acid (MAA), 1-5 portions of initiating agent di-t-butyl peroxide (DTBP), 1-5 portions of organic silicon compound and 1-5 portions of chlorinated polypropylene. The described mixed solvent includes 60-90 portions of butyl acetate, 20-28 portions of cyclohexanone, and 1-6 portions of limonene, in which the fire-resisting agent and UV-ray absorbing agent can be added.

Owner:TIANJIN LIUHONG TECH DEV

Transparent polyurethane primer and preparation method thereof

InactiveCN103740254AHigh tensile strengthImprove wear resistancePolyurea/polyurethane coatingsPolymer sciencePolyurethane coating

The invention discloses transparent polyurethane paint. The polyurethane aliphatic crosslinking type resin one-component paint, compared with linear polyurethane coating, is better than other series of coatings on aspects of paint film hardness, boiling water resistance, solvent resistance, light and color retention, resistance to firing of cigarette butts, infusion resistance and the like. Moreover, the solid component is high, the construction procedures are reduced, the transparent polyurethane paint can be rapidly dried at normal temperature, and a paint film is flat and full.

Owner:广西宾阳县荣良农业科技有限公司

Antirust corrosion-resistant rosin phenolic resin paint and preparation method thereof

InactiveCN112239607AImprove corrosion and rust resistanceImprove water resistanceAnti-corrosive paintsEpoxyPolymer science

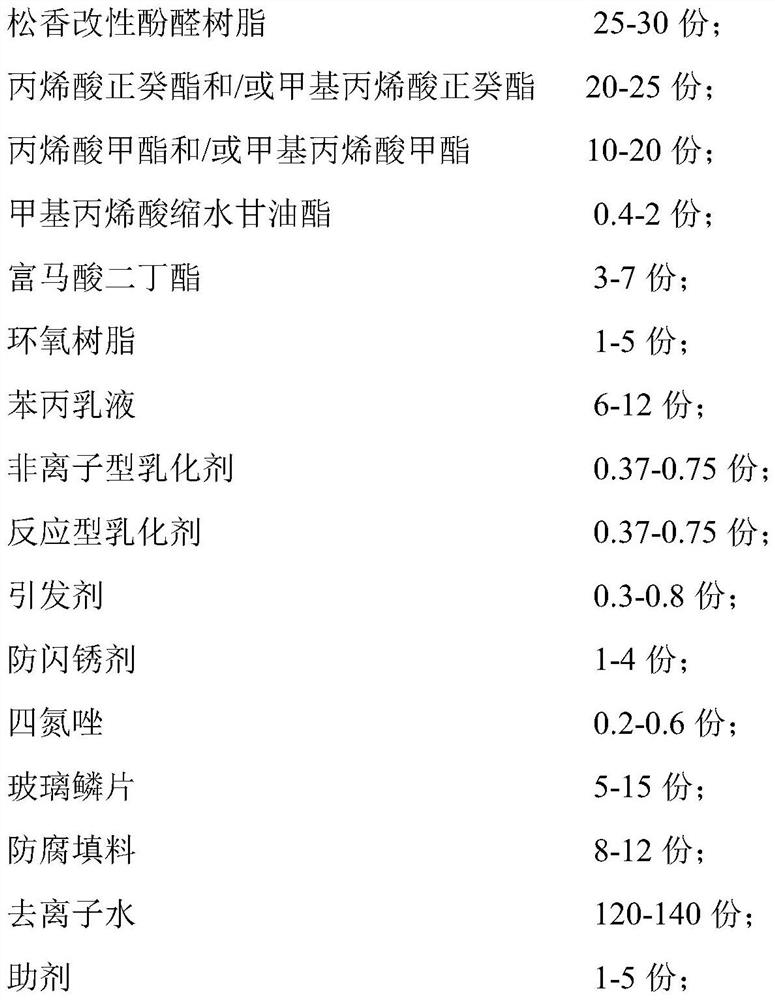

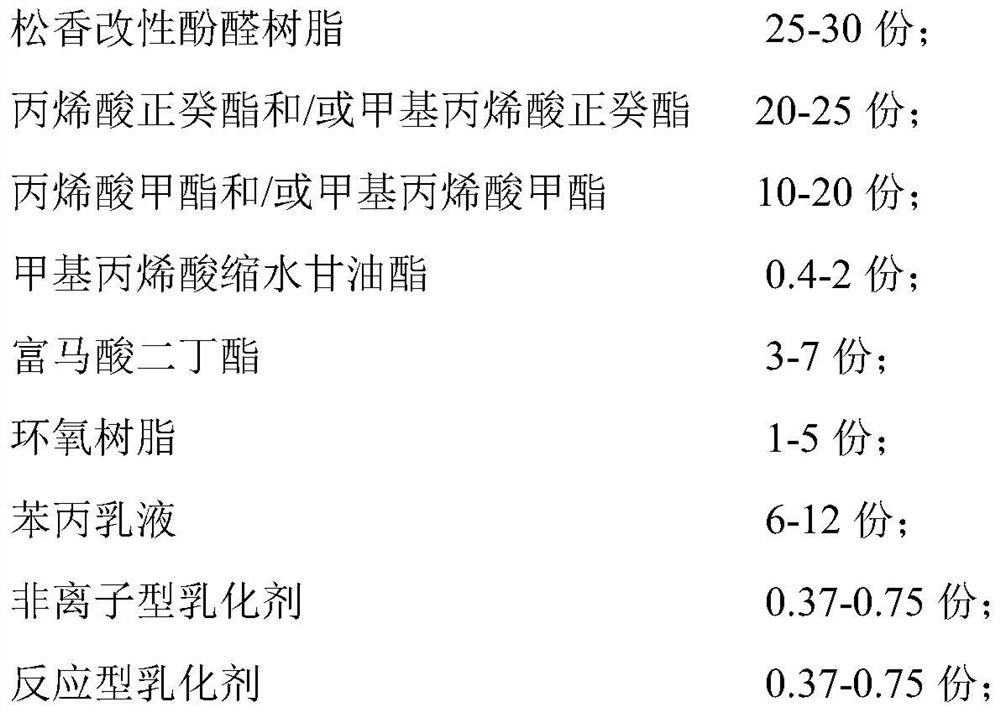

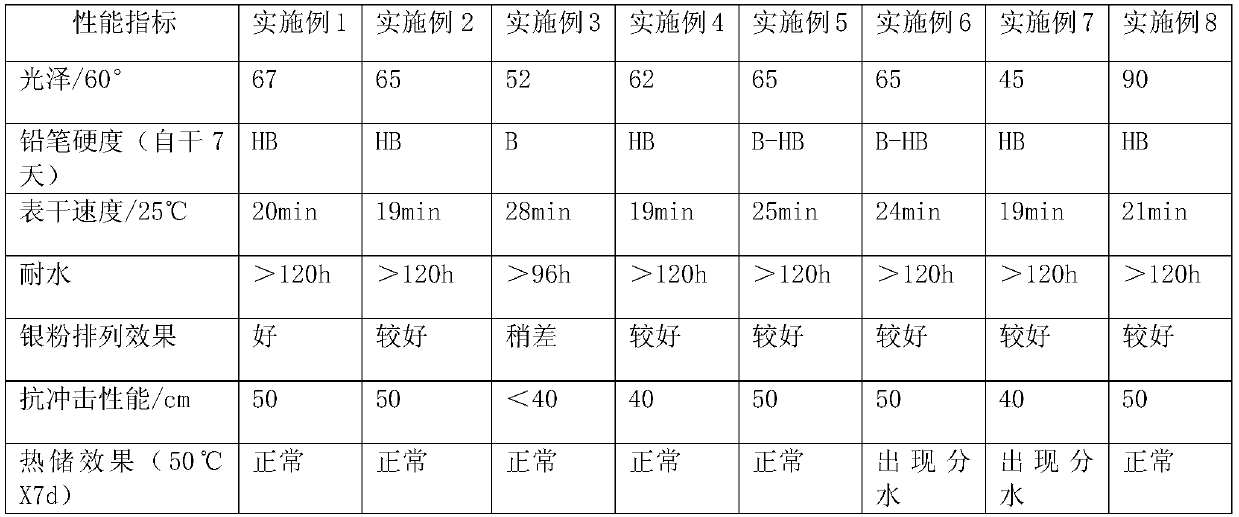

The invention provides antirust and corrosion-resistant rosin phenolic resin paint. The antirust and corrosion-resistant rosin phenolic resin paint is prepared from the following components in parts by weight: 25 to 30 parts of rosin modified phenolic resin; 20 to 25 parts of n-decyl acrylate and / or n-decyl methacrylate; 10 to 20 parts of methyl acrylate and / or methyl methacrylate; 0.4-2 part of glycidyl methacrylate; 1-5 parts of epoxy resin; 6-12 parts of a styrene-acrylic emulsion; 1-4 parts of an anti-flash rust agent; 0.2-0.6 part of tetrazole; 5-15 parts of glass flakes; 8-12 parts of anticorrosive filler, wherein the anticorrosive filler is a nitrile guanidine modified alpha-zirconium phosphate nanosheet; according to the invention, the rosin modified phenolic resin is matched withthe acrylic resin, so that the coating integrates the excellent properties of the two resins, the gloss and color retention and weather resistance of the paint layer are improved, and the nitrile guanidine modified alpha-zirconium phosphate nanosheet is used as the anticorrosive filler, thereby enhancing the rust resistance and corrosion resistance of the coating.

Owner:FENGKAI HAILAN CHEM CO LTD

PIA (meta-phthalic acid)/nanometer titania modified alkyd resin and preparation method thereof

The invention discloses a PIA (meta-phthalic acid) / nanometer titania modified alkyd resin and a preparation method thereof. The PIA / nanometer titania modified alkyd resin comprises the following raw materials: acrylic acid, methylacrylic acid, methyl methacrylate, vinyltriethoxysilane, nanometer titania, epoxy resin, castor oil, trimethylolpropane, 2,2,4-trimethyl-1,3-pentanediol, tetrachlorophthalic anhydride, PIA waste, trimellitic anhydride, triethylamine, ethyl eneglycol monobutyl ether, propylene glycol mono-n-butyl ether, lauric acid, catalytic auxiliary, benzoyl peroxide, dimethylbenzene and water. The PIA / nanometer titania modified alkyd resin provided by the invention is good in water resistance, high in hardness and excellent in comprehensive performance; the PIA waste is used, so that the cost is saved.

Owner:ANHUI JINDUN PAINT

Heat-insulating anticorrosion bi-component coating for outer wall of oil tank and preparation method thereof

InactiveCN109401475AHighlight substantive featuresSignificant progressAnti-corrosive paintsReflecting/signal paintsFoaming agentAcrylic resin

The invention relates to the field of coatings and specifically relates to a heat-insulating anticorrosion bi-component coating for an outer wall of an oil tank and a preparation method thereof. The heat-insulating anticorrosion bi-component coating comprises a component A and a component B; the component A comprises the following raw materials in parts by weight: 50-60 parts of acrylic resin, 15.0-20.0 parts of titanium dioxide, 3.0-5.0 parts of thermal reflection powder, 5.0-8.0 parts of quartz sand, 0.3-0.5 part of surface active agent, 1.5-3.0 parts of dispersing agent, 0.1-0.5 part of anti-settling agent, 0.5-1.0 part of de-foaming agent and the balance of water; the component B comprises the following raw materials in parts by weight: 70-75 parts of biuret and 0.1-2.0 parts of auxiliaries. The coating can achieve ultrahigh reflectivity, is capable of excellently reflecting solar radiation and achieving heat-insulating and cooling effects and has excellent coating hardness, abrasion resistance, alkali resistance and water resistance.

Owner:广西南宁维一防腐科技有限公司

Water-based acrylic silver powder paint suitable for mechanical equipment and preparation method thereof

InactiveCN111286243AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsPaints with free metalsSilver pasteEmulsion

The invention relates to water-based industrial coating, and particularly relates to water-based acrylic silver powder paint suitable for mechanical equipment and a preparation method thereof. The water-based acrylic silver powder paint comprises a water-based self-crosslinking acrylic emulsion, a water-based polyurethane emulsion, a cosolvent, a conventional auxiliary agent, a coalescing agent, an anti-settling agent, aluminum paste, an anti-flash-rust agent, a thickening agent and deionized water. The silver powder paint disclosed by the invention is prepared by matching the water-based self-crosslinking acrylic emulsion with better wrapping property with the proper water-based polyurethane emulsion, and the prepared finished product paint is good in storage stability, high in surface drying speed, high in hardness improvement speed, good in impact resistance and good in silver powder arrangement property. The preparation process is simple, easy to operate and low in production cost,and the working efficiency is improved.

Owner:山东七维新材料有限公司

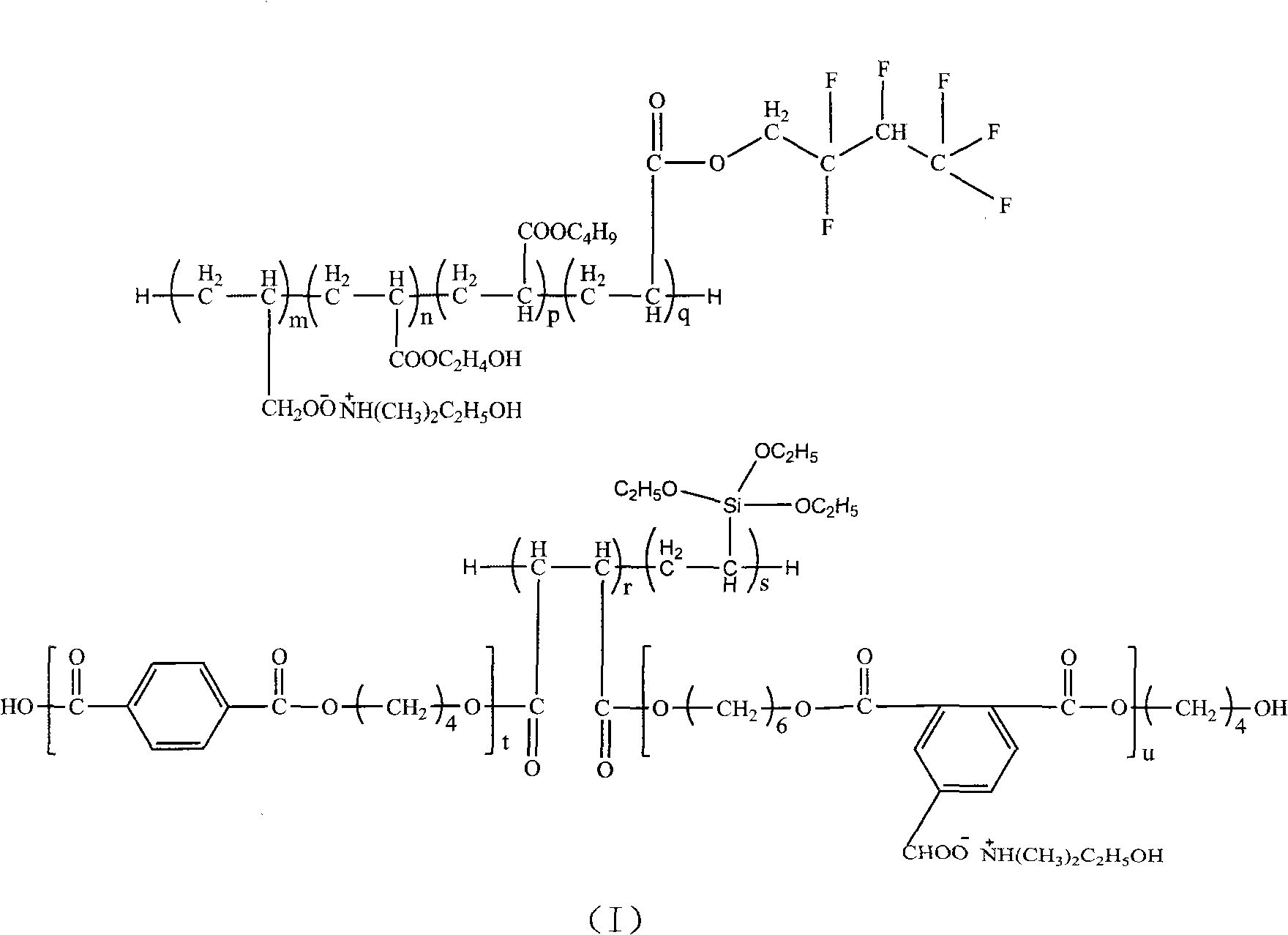

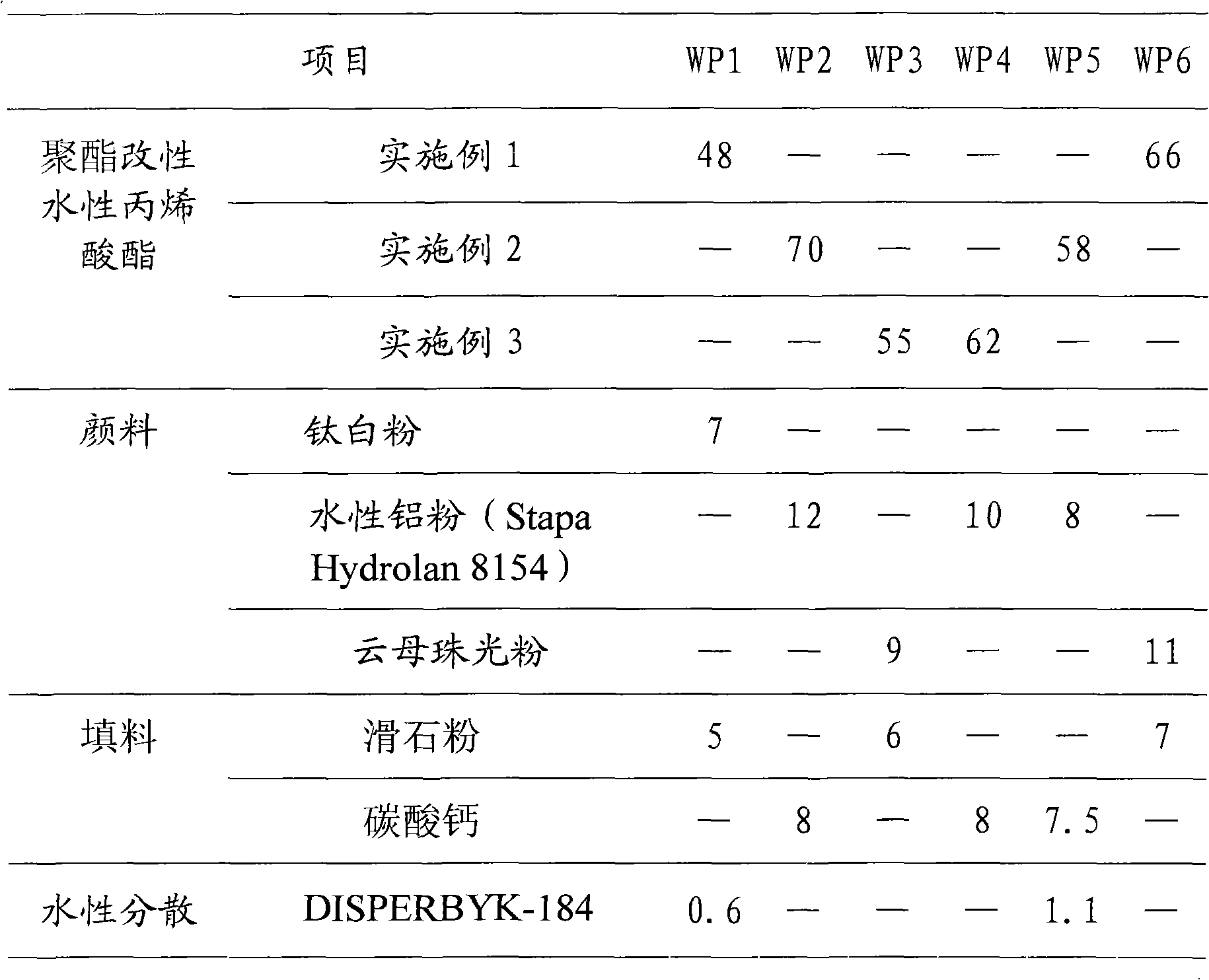

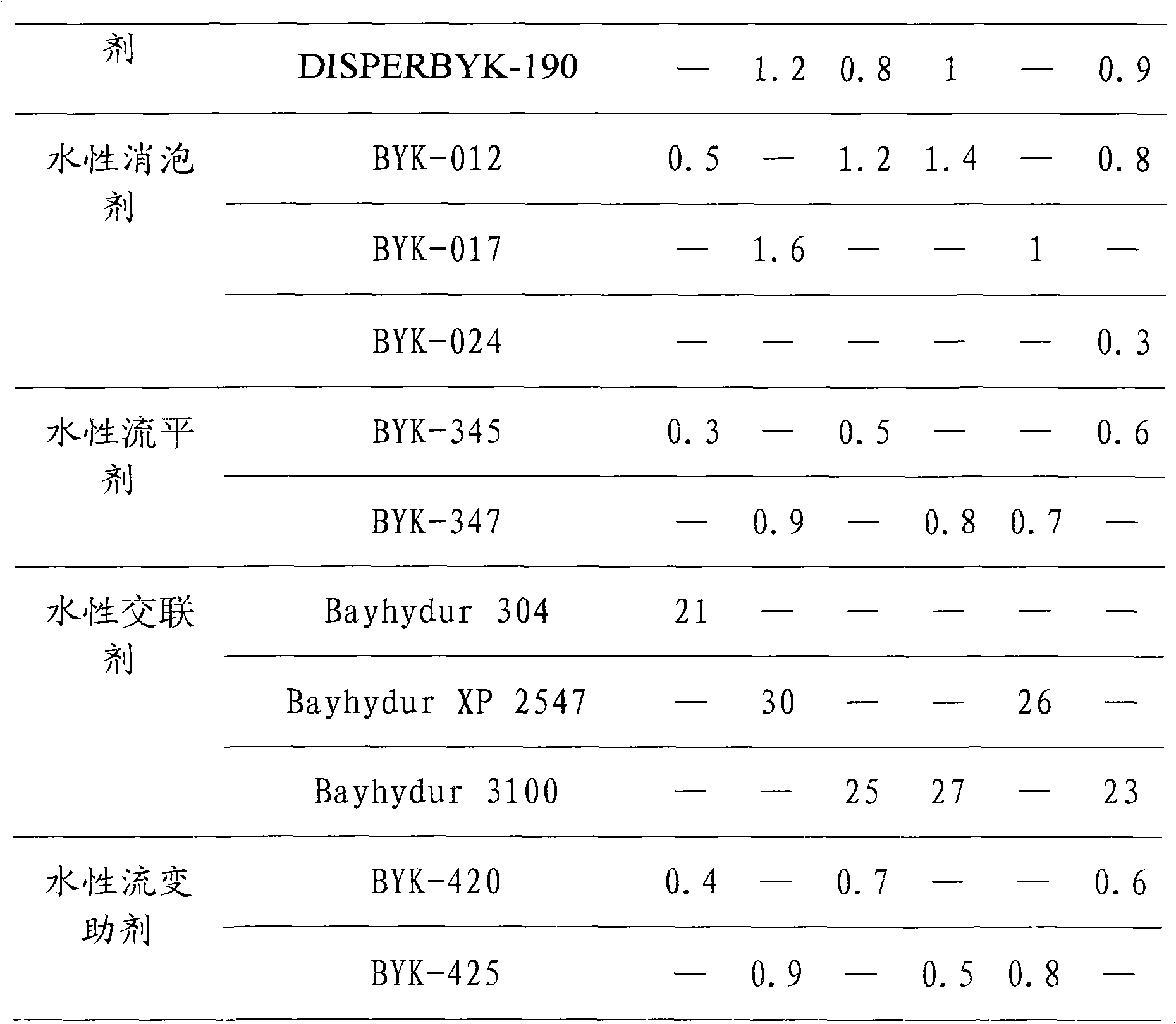

Polyester-modified aqueous acrylate and automobile aqueous paint composition

ActiveCN103387643AImprove impact performanceGood weather resistanceCoatingsPolyesterWeather resistance

The invention provides a compound with a structure of a formula (I), wherein m, n, p, q, r, s, t, and u are degrees of polymerization, m is no less than 0 and no greater than 50, n is no less than 0 and no greater than 50, p is no less than 0 and no greater than 50, q is no less than 0 and no greater than 50, r is no less than 0 and no greater than 50, s is no less than 0 and no greater than 50, t is no less than 0 and no greater than 50, and u is no less than 0 and no greater than 50. The invention also provides an automobile aqueous paint composition comprising, by weight: 48-70 parts of polyester-modified aqueous acrylate with the structure of the formula (I), 0.6-1.2 parts of an aqueous dispersing agent, 0.3-0.9 parts of an aqueous leveling agent, 0.5-1.6 parts of an aqueous defoaming agent, 5-8 parts of a filling material, 7-12 parts of a pigment, 0.4-0.9 parts of an aqueous rheological additive, and 21-30 parts of a crosslinking agent. The automobile aqueous paint provided by the invention can be polished, and has the advantages of good gloss, good gasoline resistance, and good weather resistance. The composition can be used for replacing automobile intermediate coat and basecoat, such that automobile intermediate coat coating can be eliminated.

Owner:CHANGCHUN SANHUA IND

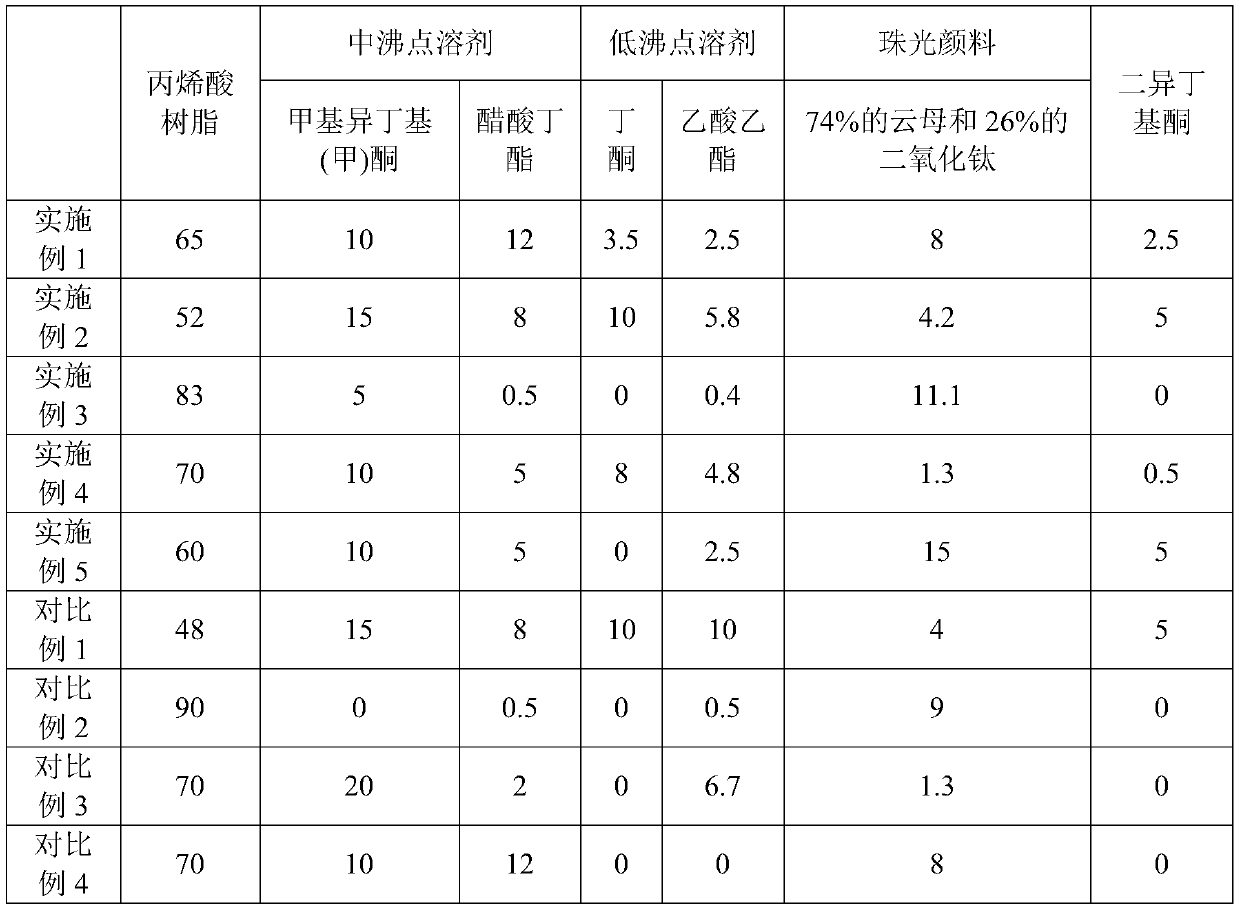

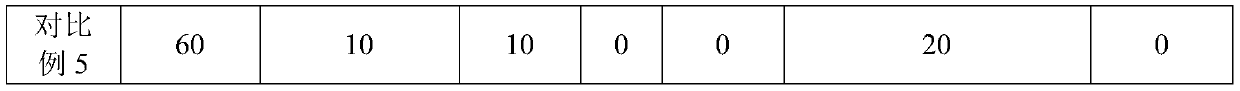

Pearlescent paint, pearlescent coating, panel and household appliance

InactiveCN110616019AImprove gloss and color retentionImproves water and chemical resistanceCoatingsDispersityWeather resistance

The invention provides pearlescent paint, a pearlescent coating, a panel and a household appliance. The pearlescent paint comprises comprises the following components in parts by weight: 52-83 partsof acrylic resin, 5-23 parts of a medium-boiling-point solvent, 0.4-16 parts of a low-boiling-point solvent and 1.3-15 parts of pearlescent pigment, the medium-boiling-point solvent comprises 5-15 parts of a medium-boiling-point ketone solvent and 0.5-12 parts of a medium-boiling-point ester solvent, and the low-boiling-point solvent comprises 0.4-16 parts of a low-boiling-point ester solvent. Themedium-boiling-point solvent is matched with the low-boiling-point solvent, so that the sufficient dispersity of the acrylic resin and the pearlescent pigment and the uniformity and smoothness of theformed pearlescent coating are ensured; and the curing speed is properly increased, so that the fineness of the formed pearlescent coating is improved, the defects of pinholes and the like caused bytoo high curing speed are avoided, the weather resistance is improved, and the particle size of the pearlescent pigment is further reduced, so that a fine pearlescent effect is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Resin composition for anti-counterfeit matrix material protective layer and anti-counterfeit matrix material

ActiveCN103709835AGood printing adaptabilityGood chemical resistanceStampsSynthetic resin layered productsCelluloseWeather resistance

The invention provides a resin composition for an anti-counterfeit matrix material protective layer and an anti-counterfeit matrix material. The anti-counterfeit matrix material comprises a surface material, a pattern layer, a protective layer, an ink layer, a dielectric layer, an adhesive layer and release paper in sequence, wherein the protective layer is formed by curing the resin composition with an isocyanate curing agent. Compared with the prior art, the resin composition and the anti-counterfeit matrix material have the beneficial effects that the protective layer takes acrylic resin as the main film forming material and the acrylic resin has better physical and mechanical properties, excellent weather resistance, chemical resistance and water resistance and high light and colour retention and has better protective effects on the pattern layer; meanwhile, the cellulose ester resin is added as an additive accelerator; the hydroxyl of the cellulse ester resin and the isocyanate curing undergo an addition polymerization reaction and then a film is formed by curing, so that the resin composition can form the film quickly; and besides, the cellulose ester resin has better hydrophilicity and lipophilicity and can endow the protective layer with better printing adaptability.

Owner:SHENZHEN SECUTEK ANTICOUNTERFEIT MATERIALS

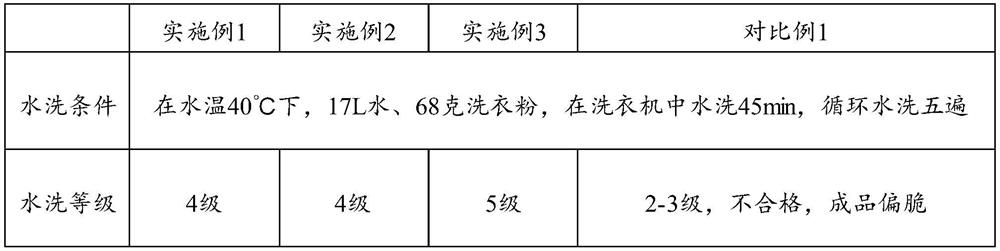

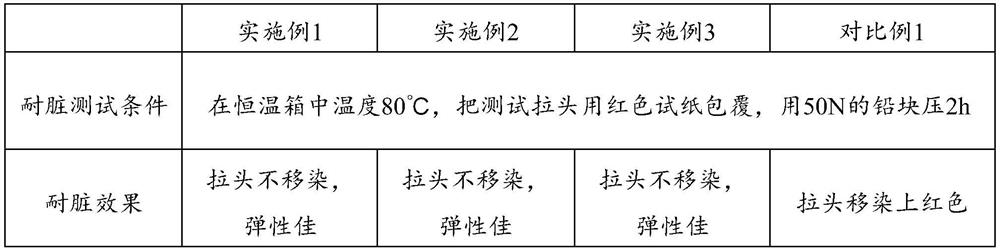

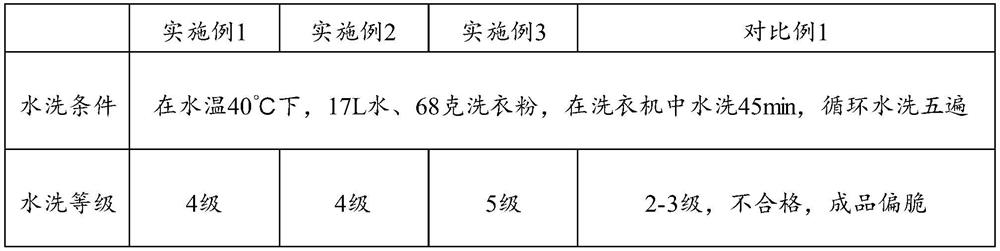

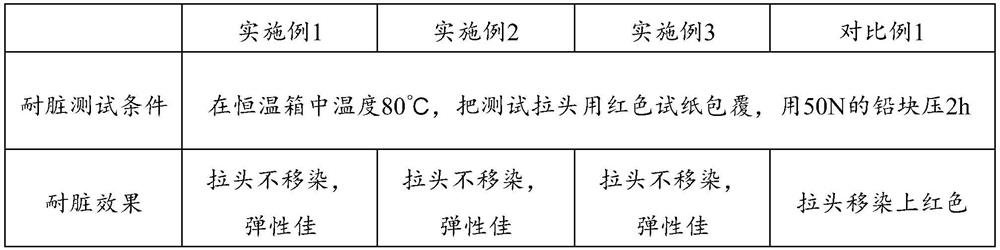

Paint suitable for puller, anti-fouling puller and preparation method thereof

ActiveCN111808519AIncrease elasticityImprove toughnessLiquid surface applicatorsAntifouling/underwater paintsPolyesterPolymer science

The invention provides paint suitable for a puller, an anti-pollution puller and a preparation method thereof. The paint suitable for the puller comprises the following components: 15wt%-23wt% of polyurethane; 15 wt%-20 wt% of polycarbonate; 1 wt%-10 wt% of polyester; 0.1 wt%-1wt% of a catalyst; 1 wt%-5 wt% of a leveling agent; 1 wt%-5 wt% of elastic powder; 5 wt%-10 wt% of matting powder; 28 wt%-59 wt% of a solvent; and the leveling agent is octamethylcyclotetrasiloxane. Preferably, the solvent is butyl ester and / or ethyl ester. Compared with the prior art, the anti-pollution puller is prepared from the paint which contains specific content components and is suitable for the puller; according to the paint suitable for the puller, the toughness, the stain resistance, the physical and mechanical properties, especially the wear resistance, the impact resistance and the scratch resistance, of a paint film are improved without influencing the appearance of the product, and meanwhile, the used paint is thick in film forming, good in insulativity, good in gloss and color retention of the paint film, good in over-baking resistance and good in weather resistance so that the high-performance anti-fouling puller is prepared.

Owner:ZHEJIANG WEIXING IND DEV

Reflective insulation coating for oil tank and preparation method thereof

InactiveCN109401476AHighlight substantive featuresSignificant progressFireproof paintsAnti-corrosive paintsInfraredFoaming agent

The invention relates to the field of coatings and specifically relates to a reflective insulation coating for an oil tank and a preparation method thereof. The reflective insulation coating is composed of a component A and a component B; the component A comprises the following raw materials: 50-60 parts of acrylic resin, 25-35 parts of titanium dioxide, 8-10 parts of heat reflection powder, 8-10parts of xylene, 5-8 parts of n-butyl acetate, 0.5-1 part of anti-settling agent, 1.5-3.0 parts of dispersing agent and 0.5-1.0 part of de-foaming agent; the component B comprises the following raw materials: 70-75 parts of biuret and 0.1-0.2 part of auxiliaries. The reflective insulation coating is capable of excellently shielding ultraviolet rays, infrared rays, and the like, is characterized bymulti-reflection and low heat absorption, is capable of effectively obstructing heat transfer and has an excellent reflecting heat-insulation effect.

Owner:广西南宁维一防腐科技有限公司

A kind of paint suitable for sliders, anti-fouling sliders and preparation method thereof

ActiveCN111808519BIncrease elasticityImprove toughnessLiquid surface applicatorsAntifouling/underwater paintsPolyesterPolymer science

The invention provides a paint suitable for a slider, an antifouling slider and a preparation method thereof; the paint suitable for a slider includes the following components: polyurethane 15wt%-23wt%; polycarbonate 15wt%-20wt% ; polyester 1wt% ~ 10wt%; catalyst 0.1wt% ~ 1wt%; leveling agent 1wt% ~ 5wt%; elastic powder 1wt% ~ 5wt%; The leveling agent is octamethylcyclotetrasiloxane. Preferably, the solvent is butyl ester and / or ethyl ester. Compared with the prior art, the present invention adopts the paint suitable for the slider with a specific content to prepare the antifouling slider; the paint suitable for the slider can improve the toughness and toughness of the paint film without affecting the appearance of the product. Stain resistance, and physical and mechanical properties, especially abrasion resistance, impact resistance and scratch resistance. At the same time, the paint used has thick conjunctiva, good insulation, good gloss and color retention of the paint film, and good overbaking resistance. , good weather resistance, so as to prepare a high-performance anti-fouling slider.

Owner:ZHEJIANG WEIXING IND DEV

Bright alkyd resin for interior decoration and furniture coating and preparation method thereof

The invention discloses a bright alkyd resin for interior decoration and furniture coating, which is composed of the following raw materials: glycerin, palmitoleic acid, benzoic acid, adipic acid, neopentyl glycol, phthalic anhydride, pentaerythritol and xylene . Its preparation method comprises the steps of: a. putting palmitoleic acid, benzoic acid, adipic acid, glycerin, neopentyl glycol, phthalic anhydride, pentaerythritol and xylene into a reactor at one time, heating and starting stirring; b. Zhongtong carbon dioxide gas protects the temperature, raises the temperature to 130°C-180°C, and keeps it warm for 1-3 hours. ; c, take a sample to measure the viscosity in step b, when the viscosity reaches a predetermined value, rapidly cool to 130°C-180°C to obtain a modified alkyd resin; d, transfer the modified alkyd resin in step c to another Add 2.5-8.5% xylene into the kettle, and mix evenly to obtain the product water-white alkyd resin liquid of the present invention.

Owner:四川巴德士新材料有限公司

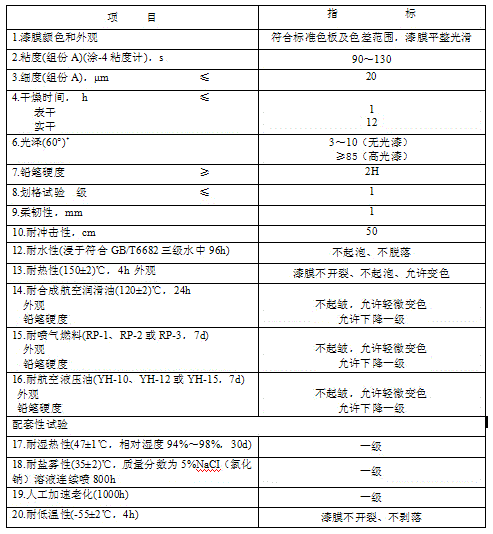

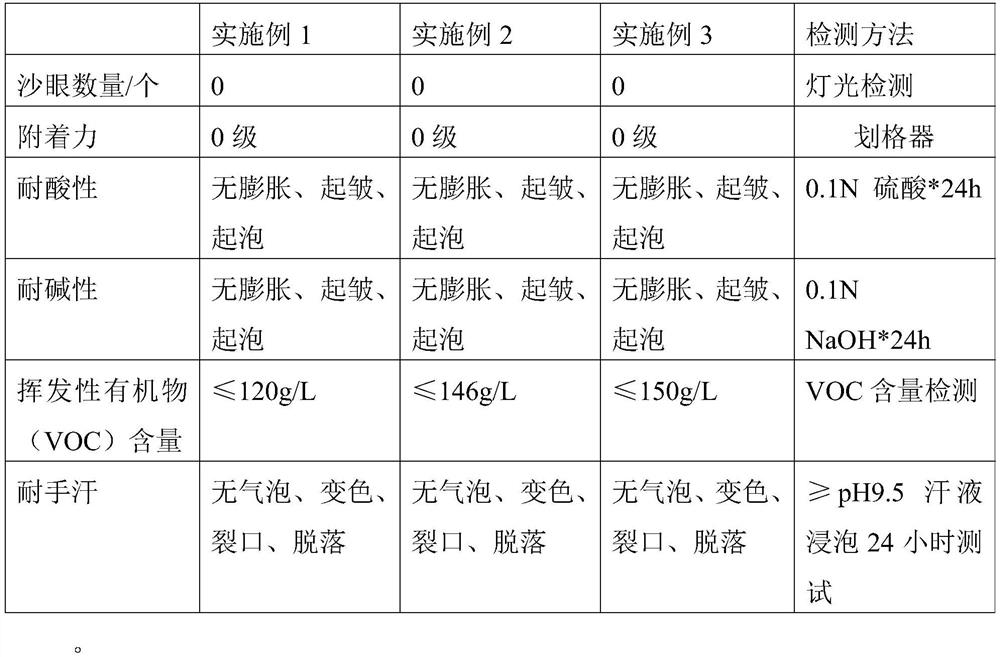

A kind of nano enamel paint for aircraft skin and preparation method thereof

ActiveCN104119751BImprove heat aging performanceGood dispersionMagnetic paintsPolyester coatingsThermal ageingAcrylic resin

The invention discloses nanometer enamel used for aircraft skin and a preparing method thereof, and belongs to the technical field of paint, mainly solving the technical problems that enamel at present has unsatisfactory ultraviolet radiation aging resistance and thermal ageing resistance and cannot meet requirements of long-term flight of aircrafts. The nanometer enamel comprises following components by weight: 3-5 parts of modified polyester resin, 30-35 parts of acrylic resin, 20-25 parts of titanium dioxide, 3-4 parts of nanometer silicon dioxide, 3-6 parts of a dispersant, 0.5-1 part of a silane coupling agent, 8-10 parts of precipitated barium sulphate, 10-15 parts of a curing agent, 15-36 parts of a mixed solvent, 0.2-0.3 part of a leveling agent, 0.2-0.3 part of a defoaming agent and 0.1-0.3 part of a catalyst. The preparing method includes steps of nanometer material pretreatment, mill base dispersion, paint mixing, filtration, and the like. The nanometer enamel has excellent ultraviolet radiation aging resistance and thermal ageing resistance at the same time of meeting common performance requirements, and can meet requirements of long-term flight of aircrafts.

Owner:西安经建油漆有限责任公司

Bromocarbon acrylic acid flame retardant protective coating

InactiveCN103194132AOvercome the shortcoming of short time limitRealize polymerizationCoatingsMethyl methacrylateEthyl ester

A bromocarbon acrylic acid flame retardant protective coating comprises by mass percentage: 13% of acrylic acid-2, 4, 6-tribromophenyl, 20% of butyl methacrylate, 5% of methyl methacrylate, 5% of styrene, 1% of acrylic acid, 10% of butyl acrylate, 5% of acrylic acid-2-ethylhexyl ester, 15%-20% of xylene, 45% of acetic ether and 1% of an initiator.

Owner:SHANGHAI DONGSHEN ELECTRONICS TECH

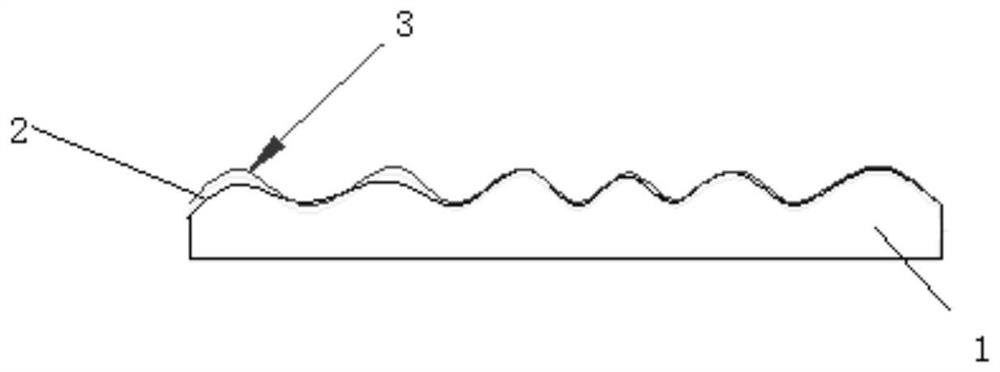

Sand-hole-free printing method for semitransparent material

ActiveCN113119615AAvoid trachomaSolve the problem of trachomaInksOther printing apparatusScreen printingPolymer science

The invention relates to a sand-hole-free printing method for a semitransparent material. The sand-hole-free printing method comprises the following steps that (1) a layer of primer is printed on a frosted surface of the semitransparent material in a silk-screen printing manner; and (2) a set color is printed on the surface of the primer. Compared with the prior art, the sand-hole-free printing method has the advantages of cost reduction, no sand holes and the like.

Owner:昊佰电子科技(上海)有限公司

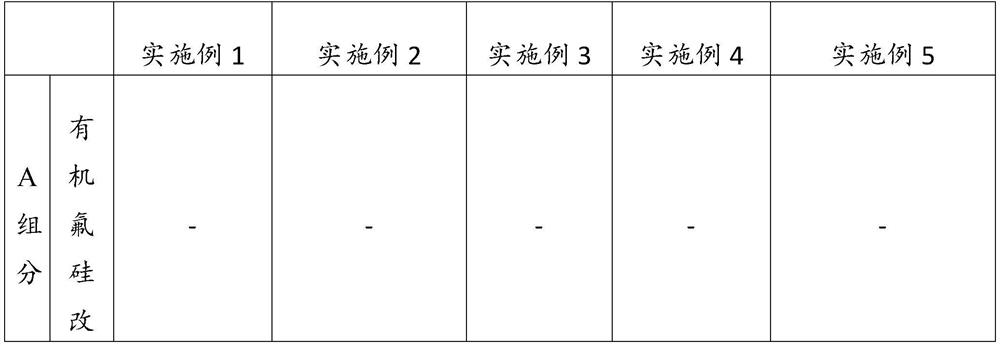

A kind of polyurea paint, coating and preparation method thereof

ActiveCN113004777BSeamlessHydrophobic with fluororesinAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolyaspartic acid

Owner:SUN YAT SEN UNIV

Resin composition for anti-counterfeit type material protective layer and anti-counterfeit type material

ActiveCN103709835BGood printing adaptabilityGood chemical resistanceStampsSynthetic resin layered productsCelluloseAcrylic resin

The invention provides a resin composition for an anti-counterfeit matrix material protective layer and an anti-counterfeit matrix material. The anti-counterfeit matrix material comprises a surface material, a pattern layer, a protective layer, an ink layer, a dielectric layer, an adhesive layer and release paper in sequence, wherein the protective layer is formed by curing the resin composition with an isocyanate curing agent. Compared with the prior art, the resin composition and the anti-counterfeit matrix material have the beneficial effects that the protective layer takes acrylic resin as the main film forming material and the acrylic resin has better physical and mechanical properties, excellent weather resistance, chemical resistance and water resistance and high light and colour retention and has better protective effects on the pattern layer; meanwhile, the cellulose ester resin is added as an additive accelerator; the hydroxyl of the cellulse ester resin and the isocyanate curing undergo an addition polymerization reaction and then a film is formed by curing, so that the resin composition can form the film quickly; and besides, the cellulose ester resin has better hydrophilicity and lipophilicity and can endow the protective layer with better printing adaptability.

Owner:SHENZHEN SECUTEK ANTICOUNTERFEIT MATERIALS

A kind of highly gloss-retaining and color-retaining acrylic acid modified polyurethane topcoat and preparation method thereof

ActiveCN109943216BStrong absorption capacityAvoid destructionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceUltraviolet lights

Owner:南京东顶新材料科技有限公司

A kind of pia/nanometer titanium dioxide modified alkyd resin and preparation method thereof

The invention discloses a PIA (meta-phthalic acid) / nanometer titania modified alkyd resin and a preparation method thereof. The PIA / nanometer titania modified alkyd resin comprises the following raw materials: acrylic acid, methylacrylic acid, methyl methacrylate, vinyltriethoxysilane, nanometer titania, epoxy resin, castor oil, trimethylolpropane, 2,2,4-trimethyl-1,3-pentanediol, tetrachlorophthalic anhydride, PIA waste, trimellitic anhydride, triethylamine, ethyl eneglycol monobutyl ether, propylene glycol mono-n-butyl ether, lauric acid, catalytic auxiliary, benzoyl peroxide, dimethylbenzene and water. The PIA / nanometer titania modified alkyd resin provided by the invention is good in water resistance, high in hardness and excellent in comprehensive performance; the PIA waste is used, so that the cost is saved.

Owner:ANHUI JINDUN PAINT

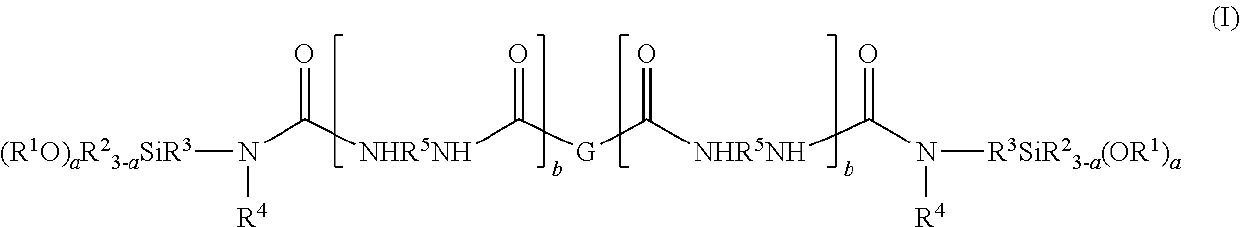

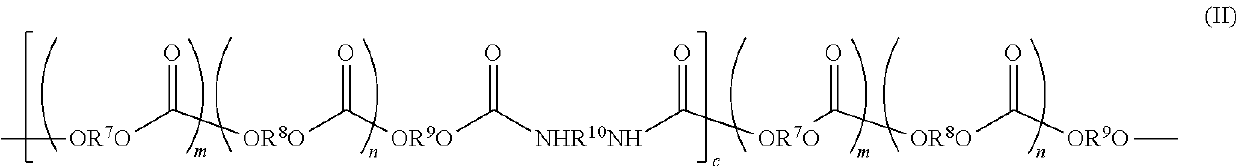

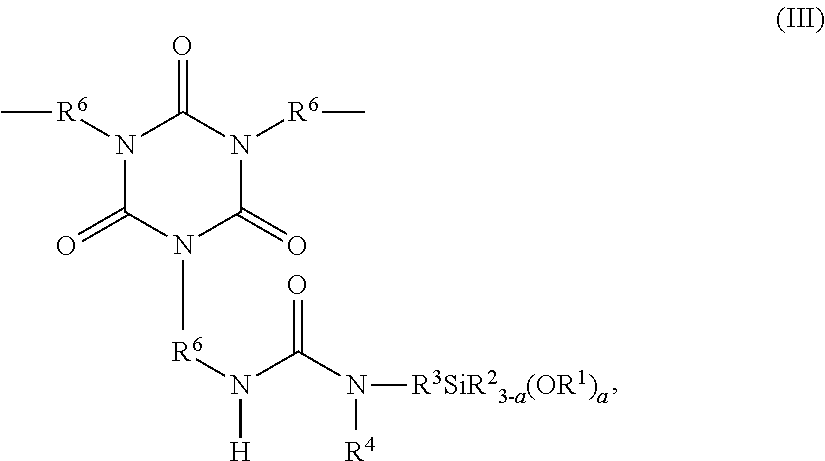

Resin compositions and methods of production

PendingUS20220145115A1Advantage in weatheringAdvantage in adhesionPolycarbonate coatingsPolyurea/polyurethane coatingsPolymer scienceEther

A resin composition containing an organic resin (i) containing carboxylic acid ester and / or ether functional groups and optionally other halo groups, amino groups, hydroxyl groups, carboxylic acid groups and cyano groups and a moisture-curable silylated polycarbonate resin (ii) derived from a copolycarbonate diol, prepared from diol(s) having even numbers of carbon atoms and odd number of carbon atoms and coatings formulated using these resin compositions.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Paint special for high density plate material and its preparation method

InactiveCN100491483CGood weather resistanceImprove water resistanceLiquid surface applicatorsCoatingsCyclohexanone(Hydroxyethyl)methacrylate

The present invention relates to a special-purpose coating for high-density plate material and its preparation method. It is made up by mixing high-molecular film-forming material, pigment, adjuvant and solvent. It is characterized by that the main component of high-molecular film-forming material of said coating is formed from (by weight portion) 40-50 portions of butyl methacrylate (BMA), 30-40 portions of styrene (ST), 10-20 portions of hydroxyethyl methacrylate (HEMA), 0.1-0.5 portion of methyl acrylic acid (MAA), 1-5 portions of initiating agent di-t-butyl peroxide (DTBP), 1-5 portions of organic silicon compound and 1-5 portions of chlorinated polypropylene. The described mixed solvent includes 60-90 portions of butyl acetate, 20-28 portions of cyclohexanone, and 1-6 portions of limonene, in which the fire-resisting agent and UV-ray absorbing agent can be added.

Owner:TIANJIN LIUHONG TECH DEV

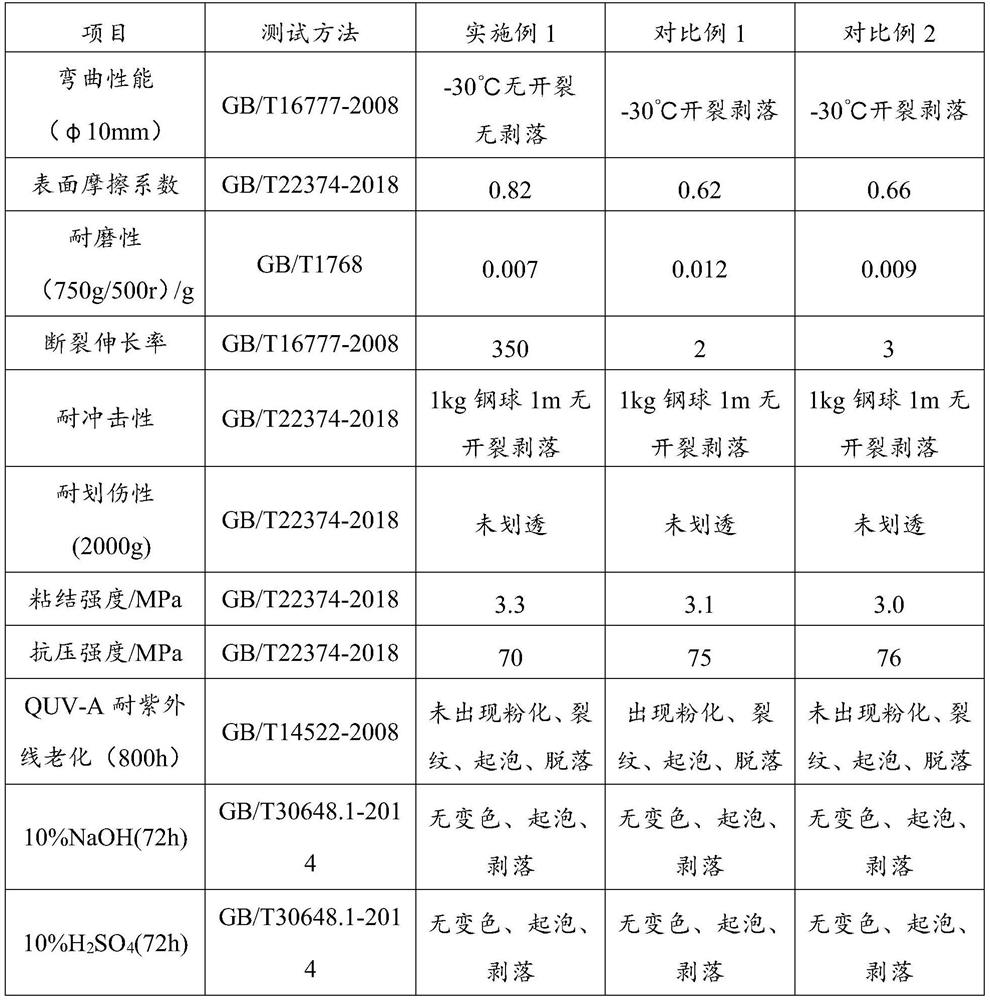

A kind of floor coating system and construction method thereof

ActiveCN111485698BIntegrity guaranteedImprove wear resistancePolyurea/polyurethane coatingsFlooringWeather resistanceCoating system

The invention belongs to the field of floor technology, and in particular relates to a floor coating system and a construction method thereof. The invention provides a floor coating system, which comprises a base coat, a heavy-duty anti-crack and anti-skid coat and a top coat which are sequentially coated on the base surface. The base coat in the present invention can penetrate well into the base surface of the floor and firmly adhere to the base surface; the heavy-duty anti-crack and anti-slip layer has a certain resilience, which can effectively slow down the cracking of the base surface of the floor , which is conducive to making the floor durable; at the same time, the heavy-duty anti-crack and anti-slip layer is conducive to increasing the wear resistance of the floor, playing a good anti-skid property, and effectively supporting a large number of buses for frequent rolling; the surface coating It has excellent chemical resistance, wear resistance, weather resistance and scratch resistance, which is beneficial to improve the gloss and color retention and wear resistance of the floor; at the same time, the top coat has excellent flexibility and can be used with heavy loads The anti-crack and anti-slip layer is matched to form a whole floor with heavy-duty anti-crack and anti-slip.

Owner:深圳市威尔地坪材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com