Bottom surface universal type alkyd antirust paint and preparation method thereof

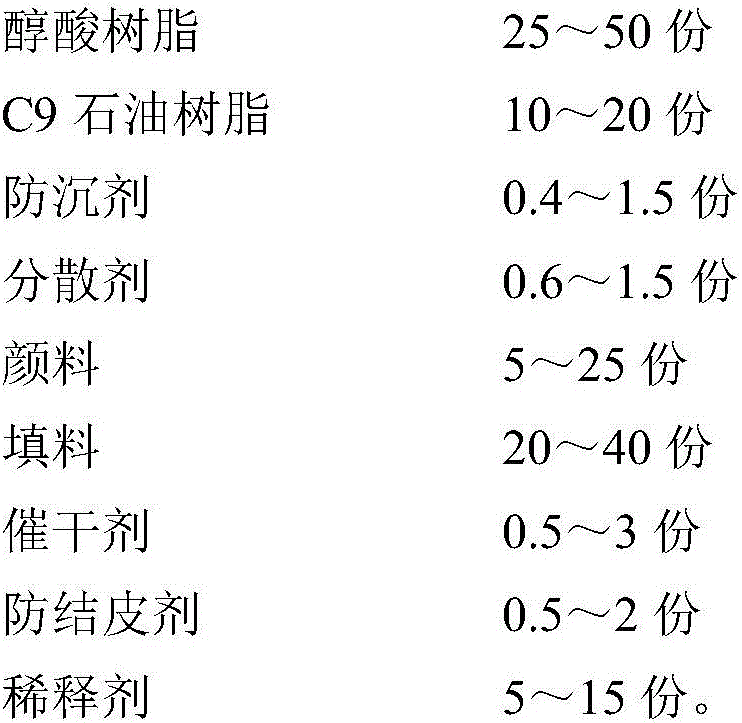

A kind of alkyd anti-rust paint, general-purpose technology, applied in the direction of anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of low hardness, unstable coloring, slow drying, etc., and achieve high hardness, gloss and color retention Sex-enhancing, fast-drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

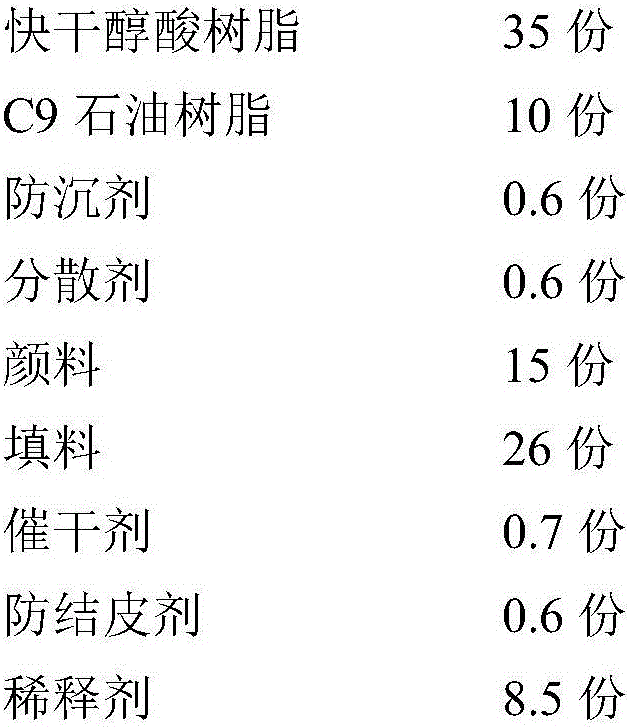

Embodiment 1

[0031] The bottom surface universal type alkyd antirust paint of the present embodiment comprises the component of following parts by weight:

[0032]

[0033] The preparation method of the general-purpose alkyd antirust paint on the bottom surface of the present embodiment comprises the following steps: (1) adding the thinner of the fast-drying alkyd resin, C9 petroleum resin, dispersant and 1 / 3 of the formula amount to disperse Axe, start stirring at 800-900 rpm, disperse for 10-15 minutes; (2) start stirring at 800-900 rpm, add the anti-settling agent of the formula and stir for 15 minutes; (3) start stirring at 800-900 rpm Minutes, add the formula amount of pigments and fillers to disperse for 30 minutes; (4) After the dispersion is completed, grind to 50 microns through a grinder; (5) After the grinding is completed, add the formula amount of drier, anti-skinning agent, and remaining diluent, After mixing well, it can be tested through paint mixing.

Embodiment 2

[0035] The bottom surface universal type alkyd antirust paint of the present embodiment comprises the component of following parts by weight:

[0036]

[0037] The preparation method of the general-purpose alkyd antirust paint for the bottom surface of this embodiment is the same as that of Embodiment 1.

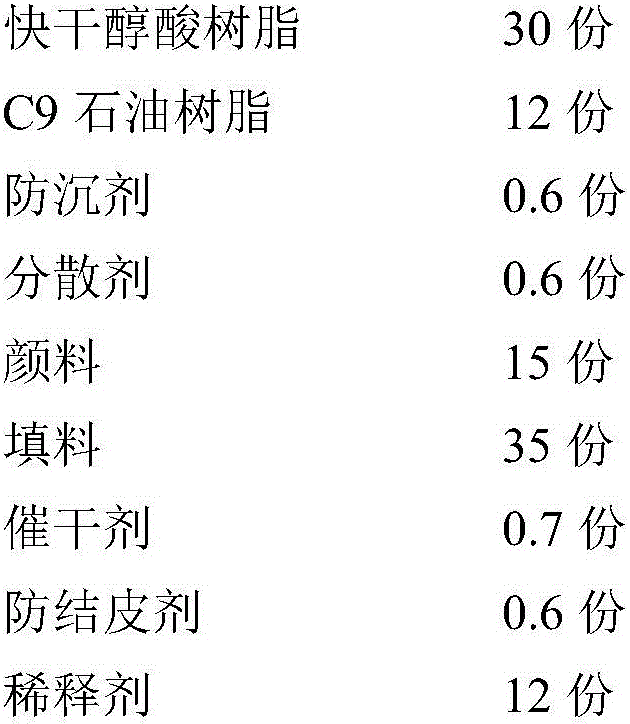

Embodiment 3

[0039] The bottom surface universal type alkyd antirust paint of the present embodiment comprises the component of following parts by weight:

[0040]

[0041] The preparation method of the general-purpose alkyd antirust paint for the bottom surface of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com