Quick-dried alkyd resin and preparation method thereof

A technology of alkyd resin and benzoic acid, which is applied in coatings, polyester coatings, etc., can solve the problems of slow drying and low hardness, achieve fast drying, good hardness, and reduce the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

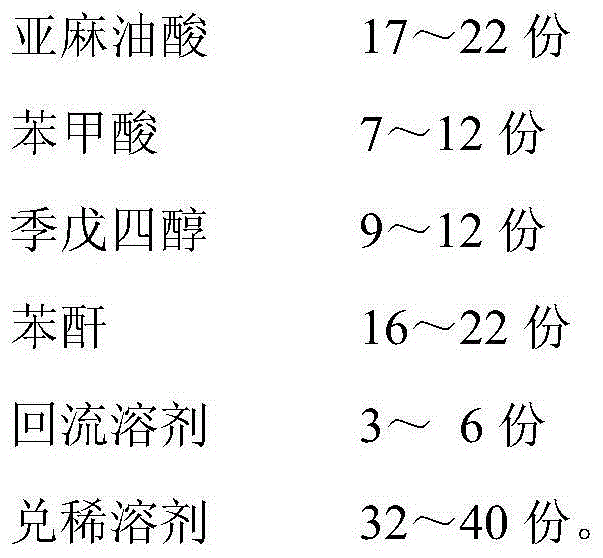

[0029] A kind of quick-drying alkyd resin, it is made up of the component of following parts by weight:

[0030]

[0031]

[0032] The following steps are used for preparation: (1) adding linolenic acid, benzoic acid, pentaerythritol, phthalic anhydride and refluxing solvent and slowly heating up to 220°C; (2) keeping the temperature at 220-230°C for 2 hours, sampling and adding dilute solvent to dilute.

Embodiment 2

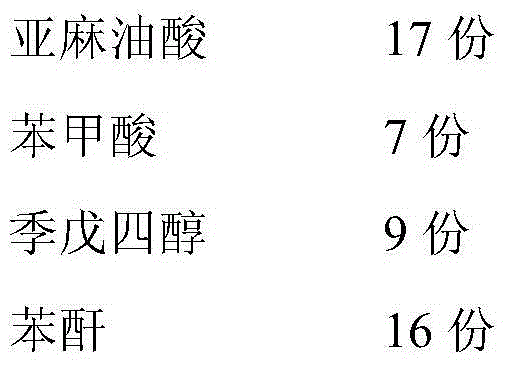

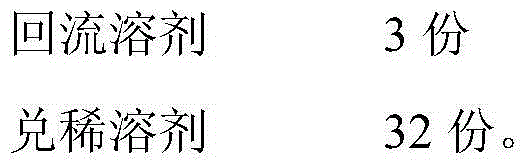

[0034] A kind of quick-drying alkyd resin, it is made up of the component of following parts by weight:

[0035]

[0036] The following steps are used for preparation: (1) adding linolenic acid, benzoic acid, pentaerythritol, phthalic anhydride and refluxing solvent and slowly heating up to 220°C; (2) keeping the temperature at 220-230°C for 2 hours, sampling and adding dilute solvent to dilute.

Embodiment 3

[0038] A kind of quick-drying alkyd resin, it is made up of the component of following parts by weight:

[0039]

[0040] The following steps are used for preparation: (1) adding linolenic acid, benzoic acid, pentaerythritol, phthalic anhydride and refluxing solvent and slowly heating up to 220°C; (2) keeping the temperature at 220-230°C for 2 hours, sampling and adding dilute solvent to dilute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com