Water-soluble acrylic alkyd resin and preparation method thereof

An acrylic alkyd, water-soluble technology, applied in the direction of coating, etc., can solve the problems of resin storage stability, poor wetting force, dry resistance, solvent resistance, limited development and application, etc. Improve durability, improve usability, and expand application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

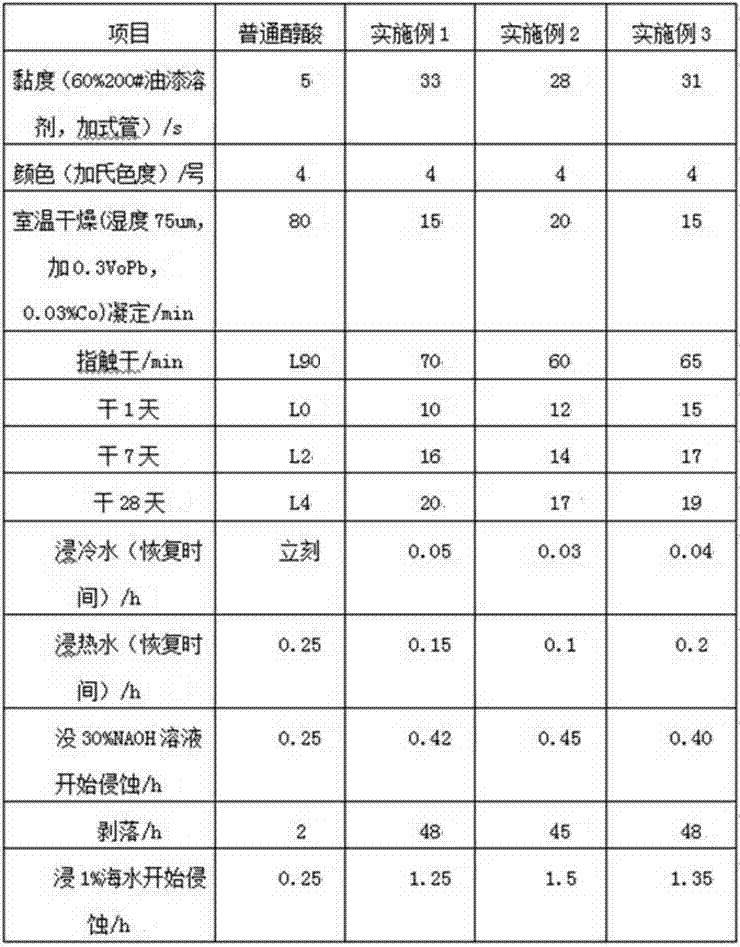

Examples

Embodiment 1

[0028] A water soluble acrylic alkyd resin made from the following weights (kg) of raw material:

[0029] Linseed oil 40

[0030] Trimethylolpropane 15

[0031] Pentaerythritol 3

[0032] Phthalic acid 2

[0033] Isophthalic acid 3

[0034] Trimellitic anhydride 8

[0035] Butyl acrylate 30

[0036] Glycidyl methacrylate 4

[0037] Acrylic 3

[0038] Hydroxyethyl methacrylate 20

[0039] Styrene 10

[0040] Ethylene glycol butyl ether 20

[0041] Xylene 5

[0042] Composite Initiator 2.

[0043] A preparation method of water-soluble acrylic alkyd resin, comprising the following steps:

[0044] (1) Weigh 75% of butyl acrylate, glycidyl methacrylate, acrylic acid, hydroxyethyl methacrylate, styrene and compound initiator according to the above formula ratio, mix well, and transfer to a constant pressure dropping funnel stand-by;

[0045] (2) Put linseed oil, trimethylolpropane, xylene, pentaerythritol, phthalic acid, and isophthalic acid into a mixing rod, ther...

Embodiment 2

[0049] A water-soluble acrylic alkyd resin is made from the following raw materials in parts by weight:

[0050] Linseed oil 45

[0051] Trimethylolpropane 18

[0052] Pentaerythritol 4

[0053] Phthalic acid 3

[0054] Isophthalic acid 4

[0055] Trimellitic anhydride 10

[0056] Butyl acrylate 35

[0057] Glycidyl methacrylate 6

[0058] Acrylic 4

[0059] Hydroxyethyl methacrylate 22

[0060] Styrene 12

[0061] Ethylene glycol butyl ether 25

[0062] Xylene 7

[0063] Composite initiator 3.

[0064] A preparation method of water-soluble acrylic alkyd resin, comprising the following steps:

[0065] (1) Weigh 80% of butyl acrylate, glycidyl methacrylate, acrylic acid, hydroxyethyl methacrylate, styrene and composite initiator according to the above formula ratio, mix well, and transfer to a constant pressure dropping funnel stand-by;

[0066] (2) Put linseed oil, trimethylolpropane, xylene, pentaerythritol, phthalic acid, and isophthalic acid into a mixing rod, t...

Embodiment 3

[0070] A water-soluble acrylic alkyd resin is made from the following raw materials in parts by weight:

[0071] Linseed oil 50

[0072] Trimethylolpropane 20

[0073] Pentaerythritol 6

[0074] Phthalic acid 5

[0075] Isophthalic acid 6

[0076] Trimellitic anhydride 12

[0077] Butyl acrylate 40

[0078] Glycidyl methacrylate 8

[0079] Acrylic 6

[0080] Hydroxyethyl methacrylate 25

[0081] Styrene 15

[0082] Ethylene glycol butyl ether 30

[0083] Xylene 10

[0084] Composite initiator 4.

[0085] A preparation method of water-soluble acrylic alkyd resin, comprising the following steps:

[0086] (1) Weigh 85% of butyl acrylate, glycidyl methacrylate, acrylic acid, hydroxyethyl methacrylate, styrene and composite initiator according to the above formula ratio, mix well, and transfer to a constant pressure dropping funnel stand-by;

[0087] (2) Put linseed oil, trimethylolpropane, xylene, pentaerythritol, phthalic acid, and isophthalic acid into a mixing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com