Sand-hole-free printing method for semitransparent material

A technology of translucent materials and printing methods, applied in printing, printing devices, inks, etc., can solve the problems of trachoma on the surface, cost increase, etc., and achieve the effects of solving trachoma problems, reducing costs, and controlling bad trachoma and poor color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

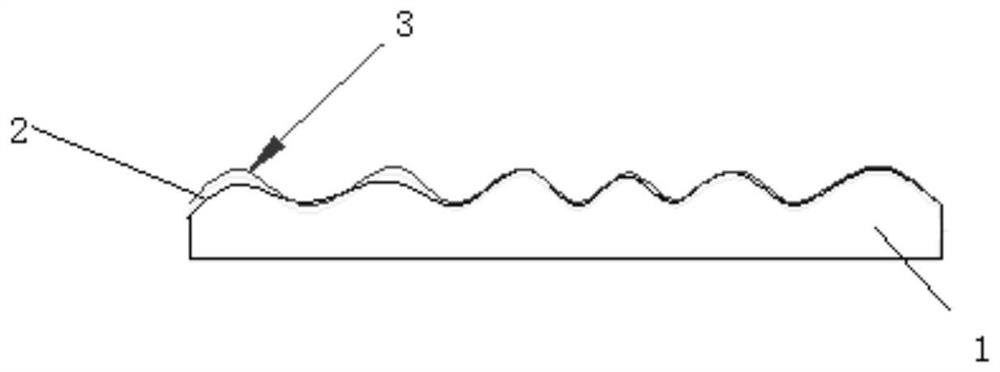

Image

Examples

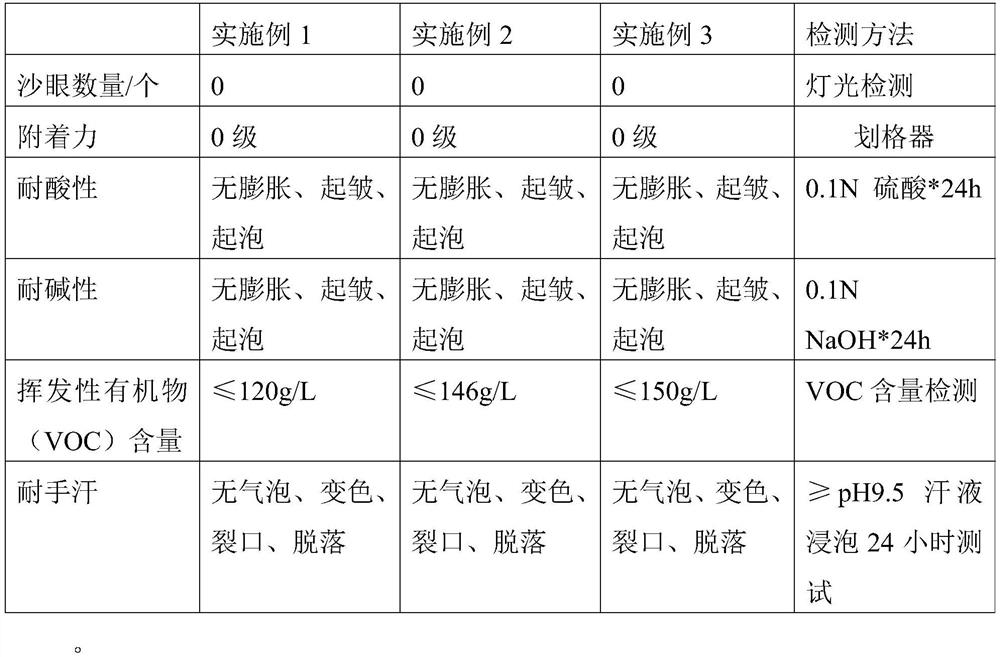

Embodiment 1

[0038] A trachoma-free printing method for translucent materials, the method comprising the following steps:

[0039] (1) Preparation of primer

[0040] 60 parts of polyurethane emulsion resin with a viscosity of 100mPa s; 25 parts of thermoplastic acrylic resin; 15 parts of vinyl acetate; 25 parts of modified silica sol; 2 parts of ammonium hydroxide; 2 parts of dibutyltin dilaurate; hydrophilic isocyanate 8 parts of curing agent; 6 parts of deionized water, stirred and mixed at room temperature for 20 minutes to obtain a primer.

[0041] The modified silica sol is prepared by mixing silica particles and silica sol at a mass ratio of 1:8, wherein the particle size of the silica particles is 500 mesh.

[0042] (2) Use screen printing to print a layer of primer on the frosted surface of the translucent glass; the conditions for screen printing are: the mesh number of the printing screen is 600 mesh, the printing thickness is 15 microns, and the printing speed is 1.5 m / Second...

Embodiment 2

[0046] A trachoma-free printing method for translucent materials, the method comprising the following steps:

[0047] (1) Preparation of primer

[0048] 70 parts of polyurethane emulsion resin with a viscosity of 50 mPa s; 30 parts of thermoplastic acrylic resin; 10 parts of vinyl acetate; 20 parts of modified silica sol; 1 part of ammonium hydroxide; 1 part of dibutyltin dilaurate; hydrophilic isocyanate 5 parts of curing agent; 3 parts of deionized water, stirred and mixed at room temperature for 10 minutes to obtain primer.

[0049] The modified silica sol is prepared by mixing silica particles and silica sol at a mass ratio of 1:6, wherein the particle size of the silica particles is 400 mesh.

[0050] (2) Print a layer of primer on the matte surface of the translucent crystal by screen printing; the conditions of screen printing are: the mesh number of the printing screen is 600 mesh, the printing thickness is 10 microns, and the printing speed is 1.0 m / Second, the dis...

Embodiment 3

[0053] A trachoma-free printing method for translucent materials, the method comprising the following steps:

[0054] (1) Preparation of primer

[0055] 50 parts of polyurethane emulsion resin with a viscosity of 150mPa·s; 20 parts of thermoplastic acrylic resin; 20 parts of vinyl acetate; 30 parts of modified silica sol; 3 parts of ammonium hydroxide; 3 parts of dibutyltin dilaurate; hydrophilic isocyanate 10 parts of curing agent; 10 parts of propylene glycol methyl ether acetate, stirred and mixed at room temperature for 30 minutes to obtain a primer.

[0056] The modified silica sol is prepared by mixing silica particles and silica sol at a mass ratio of 1:10, wherein the particle size of the silica particles is 600 mesh.

[0057] (2) Use screen printing to print a layer of primer on the frosted surface of translucent plastic; the conditions for screen printing are: the mesh number of the printing screen is 800 mesh, the printing thickness is 20 microns, and the printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com