Roll molding process for nylon particles

A technology of rotomolding and nylon, applied in the direction of coating, etc., can solve the problems of powder application precedent not yet found, immature application, narrow range, etc., to solve the poor coating of inserts, solve the problem of moisture absorption, and improve fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

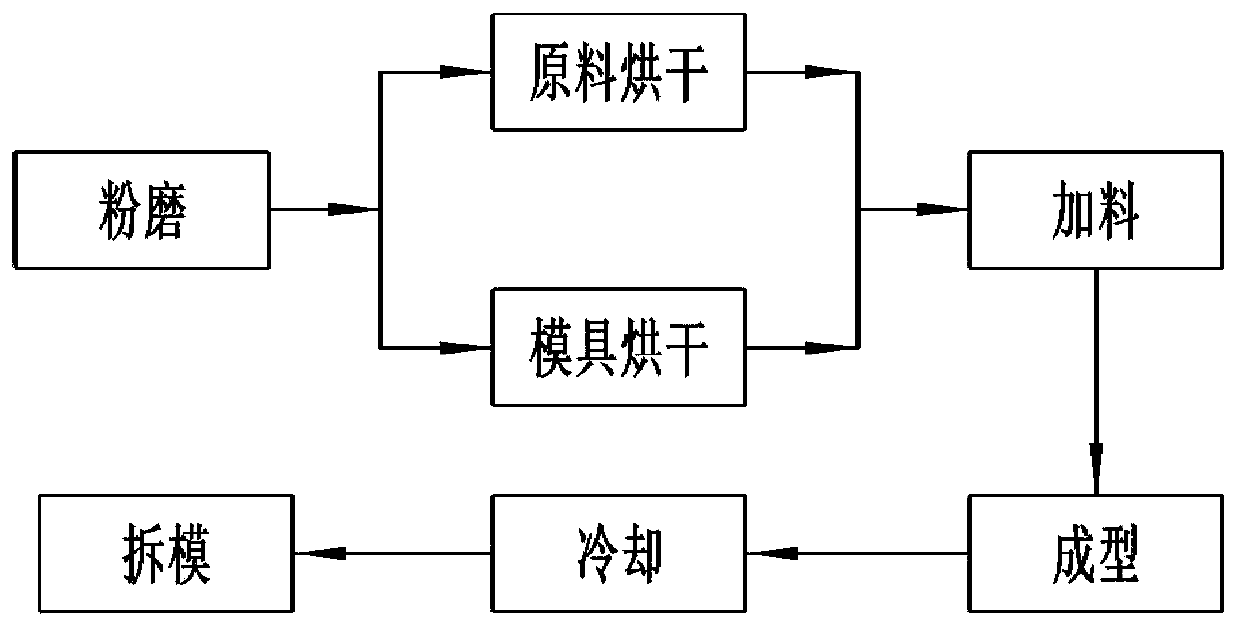

[0020] A rotational molding process using nylon such as figure 1 shown, including the following steps:

[0021] A. Milling: Nylon particles are ground in the mill using low-temperature liquid nitrogen technology in a constant temperature and humidity environment, and dry air is sent into the mill to form a swirling airflow, so that the nylon powder is fully collided and self-grinded to form nylon powder. Nylon powder round particles accounted for more than 96%.

[0022] Nylon particles can be one or more kinds of nylon particles produced by Nanjing Julong Technology, BASF in the United States, Kuibyshev in Russia, etc. In the constant temperature and humidity workshop (constant temperature 23°C, air humidity 40%), low temperature liquid nitrogen process is used to grind granular nylon. After grinding for 25min-40min, a 30KW fan sends dry air to the inside of the mill to form a swirling airflow. Let the nylon powder fully collide and self-grind for 20-30 minutes, so that the ...

Embodiment 2

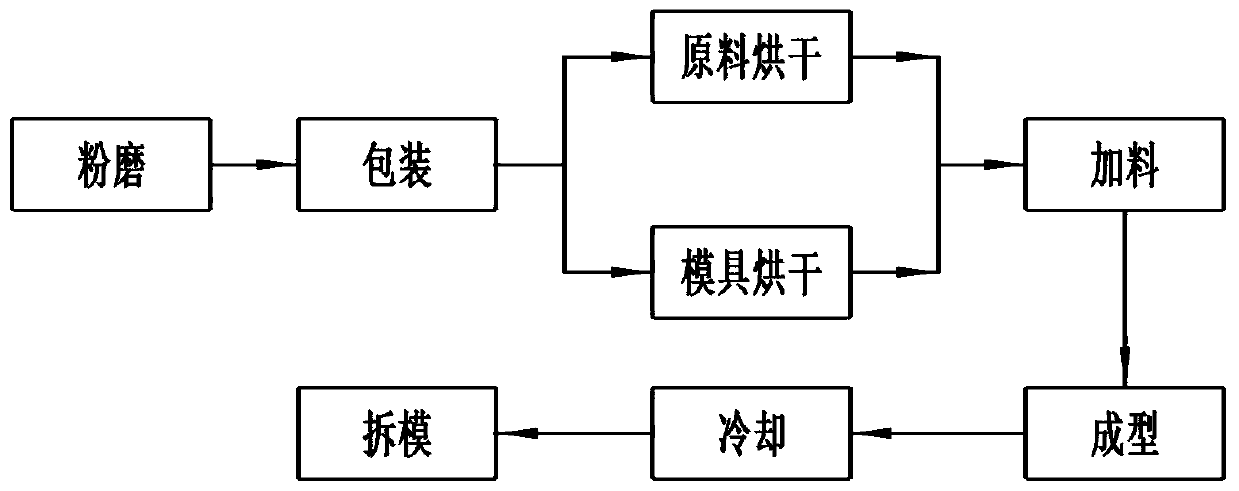

[0051] A rotational molding process that adopts nylon, different from embodiment 1, such as figure 2 As shown, a step of packaging is added between grinding and drying. The packaging is to fill the nylon powder into an aluminum foil packaging bag and seal it. The outer packaging is packaged in kraft paper and placed in a dry place for later use.

[0052] The method can separate the two processes of grinding and drying in time series, which is convenient for production.

Embodiment 3

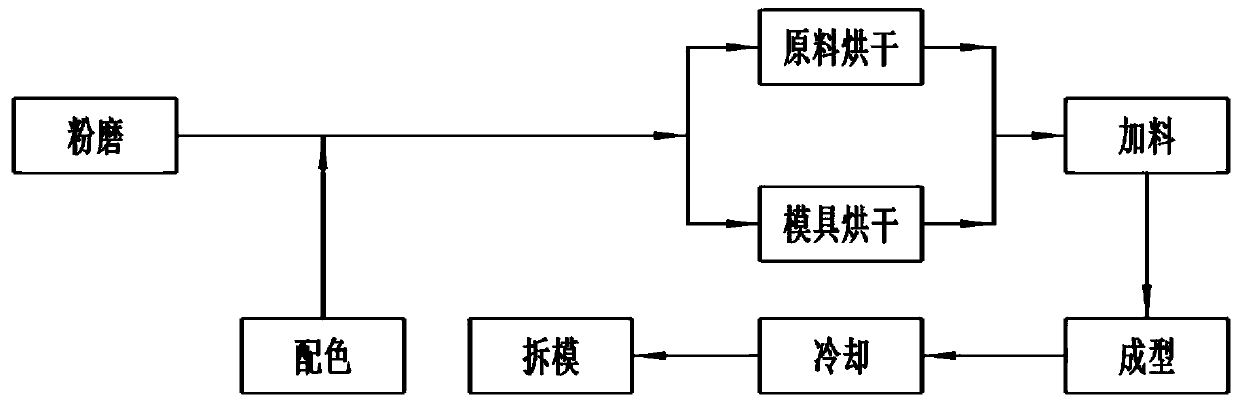

[0054] A rotational molding process that adopts nylon, different from embodiment 1, such as image 3 As shown, the color matching step is added between grinding and drying, and the color matching is to add the toner and nylon powder into the mixer and stir for 15-25 minutes.

[0055] The effect of this method is to produce rotationally molded products of different colors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com