Rapid sand mold preparation method

A sand mold and fast technology, which is applied in the direction of casting molding equipment, cores, casting molds, etc., can solve the problems that the original sand mold is easy to flow, easy to be affected by dust, and affect the casting effect, so as to avoid trachoma or cracks and avoid the influence of dust , easy-to-grasp effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] In the picture:

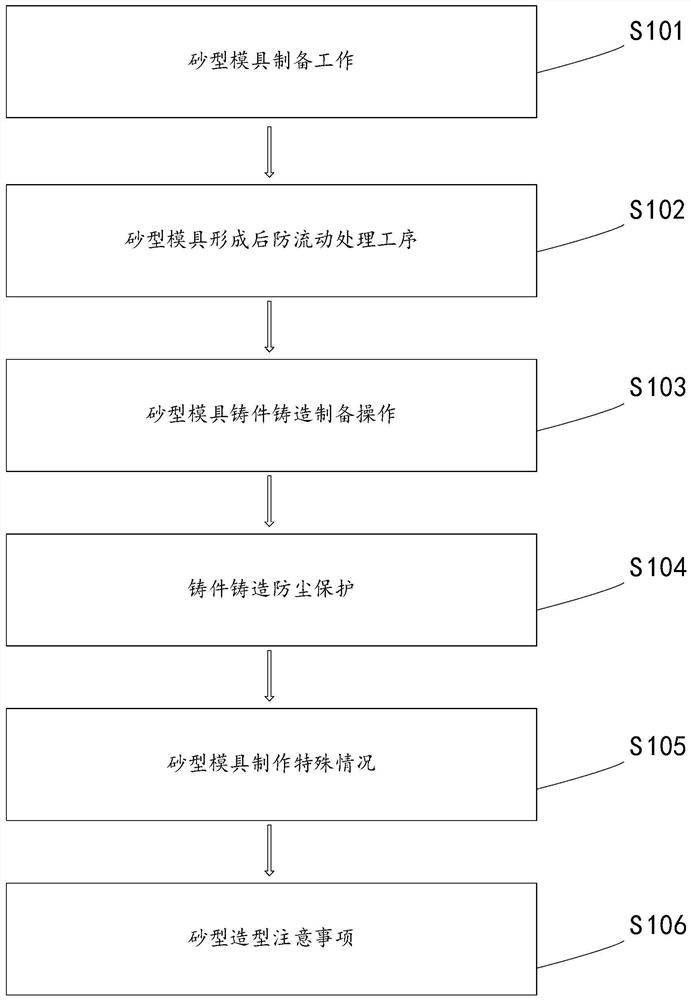

[0033] as attached figure 1 shown

[0034] A kind of rapid sand mold preparation method specifically comprises the following steps:

[0035] S101: Sand mold preparation work, clean the raw sand, remove impurities and dust, filter the raw sand through a stainless steel mesh screen, and then rinse it. After washing, it is dried, and the dried raw sand is placed in the In the sand box, leave a mold cavity in the sand box, and then bond the original sand with an adhesive to form a sand mold;

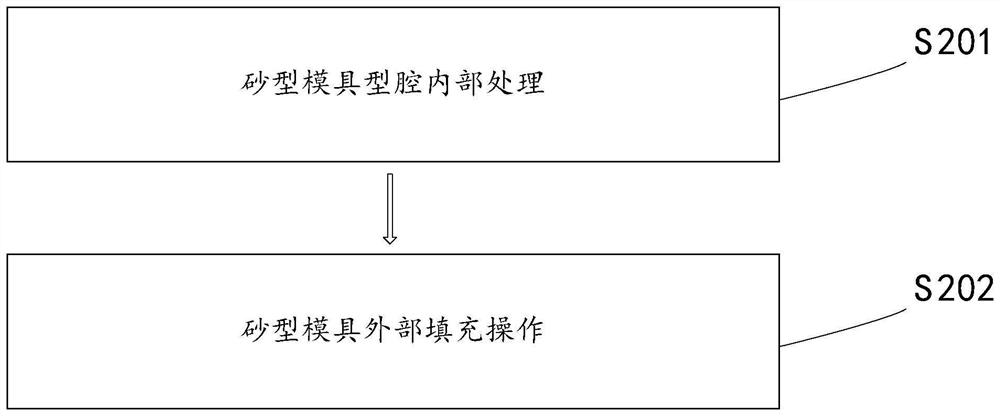

[0036] S102: Anti-flow treatment process after the sand mold is formed, combined with the attached figure 2 As shown, it specifically includes the following steps:

[0037] S201: Internal treatment of the cavity of the sand mold. The inner wall of the formed cavity is smeared with smooth auxiliary materials. After the smearing, the inner wall of the cavity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com