Method for manufacturing ceramic reinforcement metal matrix composite material using preform cast-infiltration through inductance coil transverse flux heating

A composite material and transverse magnetic flux technology, applied in the field of composite materials, can solve the problems of large appearance size, difficulty in casting the mold into the heating furnace, and difficulty in obtaining high quality, so as to achieve sufficient casting infiltration process, good consistency, Guarantee the effect of casting penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

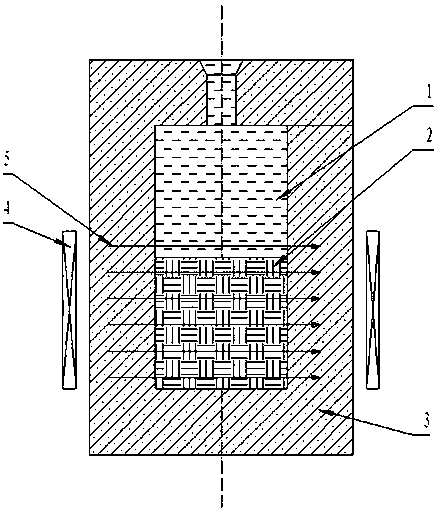

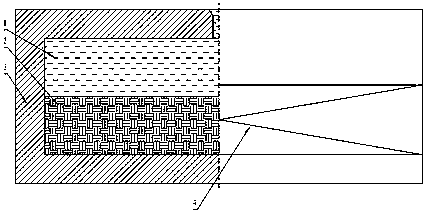

[0031] Example 1. Casting infiltration of vertical mill roller sleeve inserts

[0032] The roller sleeve insert is a typical ceramic particle reinforced metal matrix composite wear-resistant material, which is made into a roller sleeve after secondary casting, and is used as a wear-resistant part of a vertical mill. At present, there are many domestic research and development units, but due to quality reasons, especially the combination between ceramic particles and high-chromium cast iron is not tight enough, that is, the compound is not good enough, and the quality is unstable, so far, it has not been applied in the market.

[0033] Use the implementation steps of the present invention as follows:

[0034] Molding: Molding with water glass quartz sand, coating the surface of the sand mold with magnesia paint, and then preheating the sand mold at 300°C to 500°C.

[0035] Make the prefabricated body of the ceramic reinforcement and preheat it to 500°C to 600°C, or put it in t...

Embodiment 2

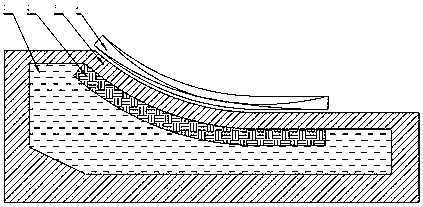

[0041] Example 2 Cast infiltration of vertical mill disc liner

[0042] Molding: Molding with water glass quartz sand, coating the surface of the sand mold with magnesia paint, and then preheating the sand mold at 300°C to 500°C.

[0043] Make the prefabricated body of the ceramic reinforcement and preheat it to 500°C to 600°C, or put it in the sand mold at a set position and preheat it together with the mold.

[0044] Fit the mold, and move the composite part of the sand mold (casting mold) to the side of the heating coil, and put the side containing the prefabricated block close to the surface of the coil, and the surface of the coil matches the curved surface of the composite part in the sand mold. like image 3 .

[0045] Pour high-chromium cast iron molten metal into the sand mold, and at the same time energize the electromagnetic induction coil to raise the temperature of the molten metal by 100-200°C within 60 to 90 seconds to reach the required infiltration temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com