Polyester-modified aqueous acrylate and automobile aqueous paint composition

A water-based acrylate and polyester modification technology, applied in coatings and other directions, can solve problems such as performance gaps, and achieve the effects of enhancing weather resistance, enhancing gloss and color retention, and improving sand and stone impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

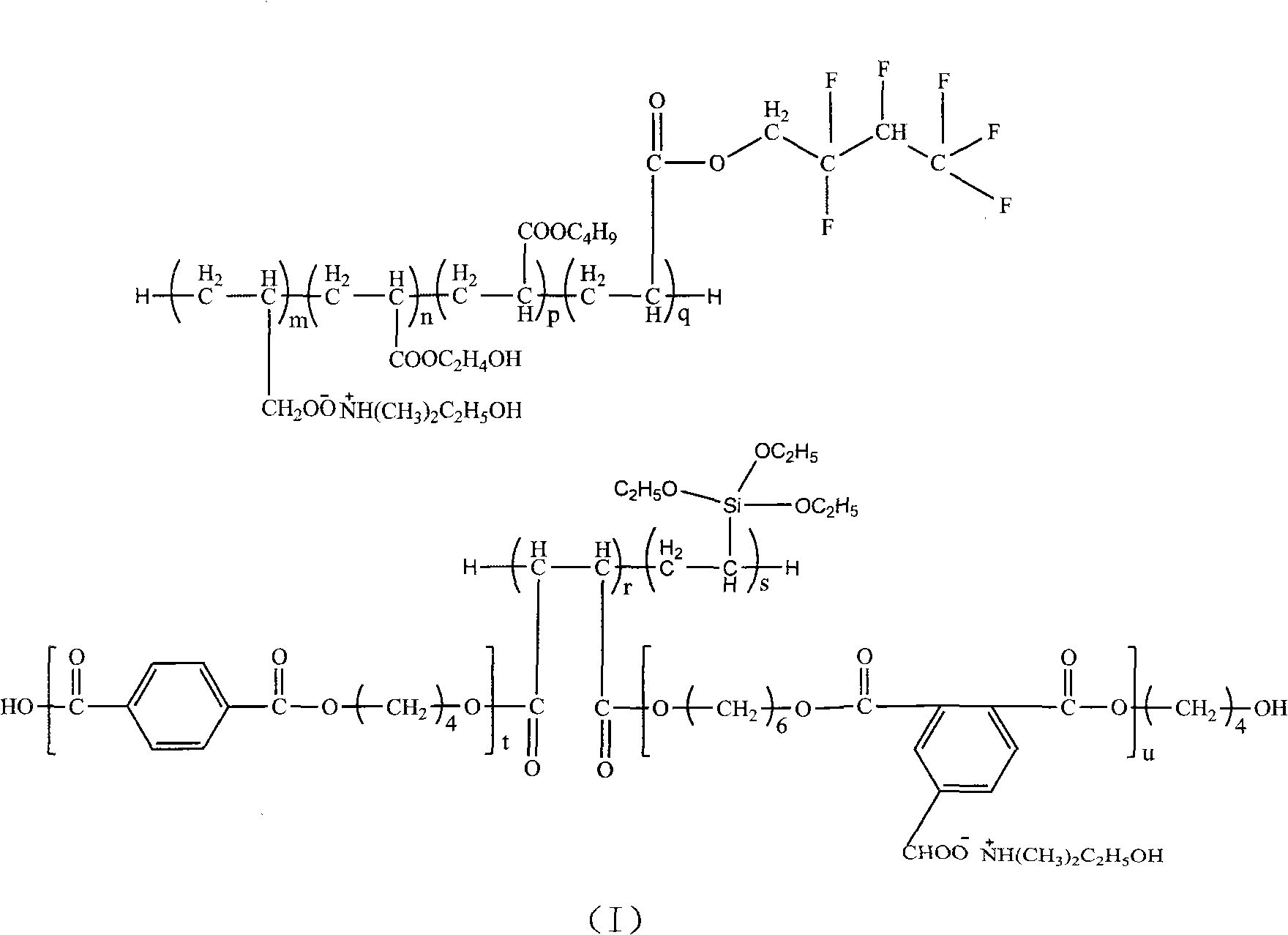

Method used

Image

Examples

Embodiment 1

[0024] Add 20g terephthalic acid, 22g butanediol, 26g hexanediol, 0.003g dibutyltin oxide, 6g cis-butane into a four-necked flask equipped with a stirrer, thermometer, condenser, water separator and nitrogen protection Acrylic anhydride and 0.001g hydroquinone were heated to 165°C, the material began to melt, stirred at 500rpm, gradually heated to 235°C within 3h, and continued to esterify for 2h. Vacuum until the vacuum degree was less than -0.098MPa for reduction Pressure, remove the small molecule products and water generated in the polycondensation reaction, react until the acid value is less than 5mg KOH / g, add 3g trimellitic anhydride, react for 1h, stop the reaction, cool to 65°C, add butylene glycol methyl ether to obtain the first intermediate product.

[0025] 3g vinyl triethoxysiloxane, 5g acrylic acid, 4g butyl acrylate, 7g hydroxyethyl acrylate, 4g hexafluorobutyl acrylate, 0.001g dodecyl mercaptan, 0.0005g azobisisobutyronitrile Stir uniformly, then, add dropwise t...

Embodiment 2

[0027] Add 5g terephthalic acid, 32g butanediol, 6g hexanediol, 0.003g dibutyltin oxide, 16g cis-butane into a four-neck flask equipped with a stirrer, thermometer, condenser, water separator and nitrogen protection Acrylic anhydride and 0.001g hydroquinone were heated to 165°C, the material began to melt, stirred at 500rpm, gradually heated to 235°C within 3h, and continued to esterify for 2h. Vacuum until the vacuum degree was less than -0.098MPa for reduction Pressure, remove the small molecule products and water generated in the polycondensation reaction, react until the acid value is less than 5mg KOH / g, add 8g trimellitic anhydride, react for 1h, stop the reaction, reduce the temperature to 65 ℃, add butanediol methyl ether to obtain the first intermediate product.

[0028] 7g vinyl triethoxysiloxane, 8g acrylic acid, 3g butyl acrylate, 10g hydroxyethyl acrylate, 6g hexafluorobutyl acrylate, 0.001g dodecyl mercaptan, 0.0005g azobisisobutyronitrile Stir uniformly, then add ...

Embodiment 3

[0031] Add 26g terephthalic acid, 32g butanediol, 16g hexanediol, 0.003g dibutyltin oxide, 8g cis-butane into a four-neck flask equipped with a stirrer, thermometer, condenser, water separator and nitrogen protection Acrylic anhydride and 0.001g hydroquinone were heated to 165°C, the material began to melt, stirred at 500rpm, gradually heated to 235°C within 3h, and continued to esterify for 2h. Vacuum until the vacuum degree was less than -0.098MPa for reduction Press to remove the small molecule products and water generated in the polycondensation reaction, and react until the acid value is less than 5mg KOH / g, add 5g trimellitic anhydride, react for 1h, stop the reaction, cool to 65°C, add butanediol methyl ether to obtain the first intermediate product.

[0032] Combine 5g vinyl triethoxysiloxane, 6g acrylic acid, 3g butyl acrylate, 4g hydroxyethyl acrylate, 8g hexafluorobutyl acrylate, 0.001g dodecyl mercaptan, 0.0005g azobisisobutyronitrile Stir uniformly, then add dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com