Method and equipment for manufacturing garbage derived fuel pack

A garbage-derived fuel and garbage-derived technology, applied in the direction of biofuel, fuel, solid fuel, etc., can solve the problems of difficult transportation, poor molding effect, poor packaging effect, etc., and achieve the effect of convenient transportation and improved packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

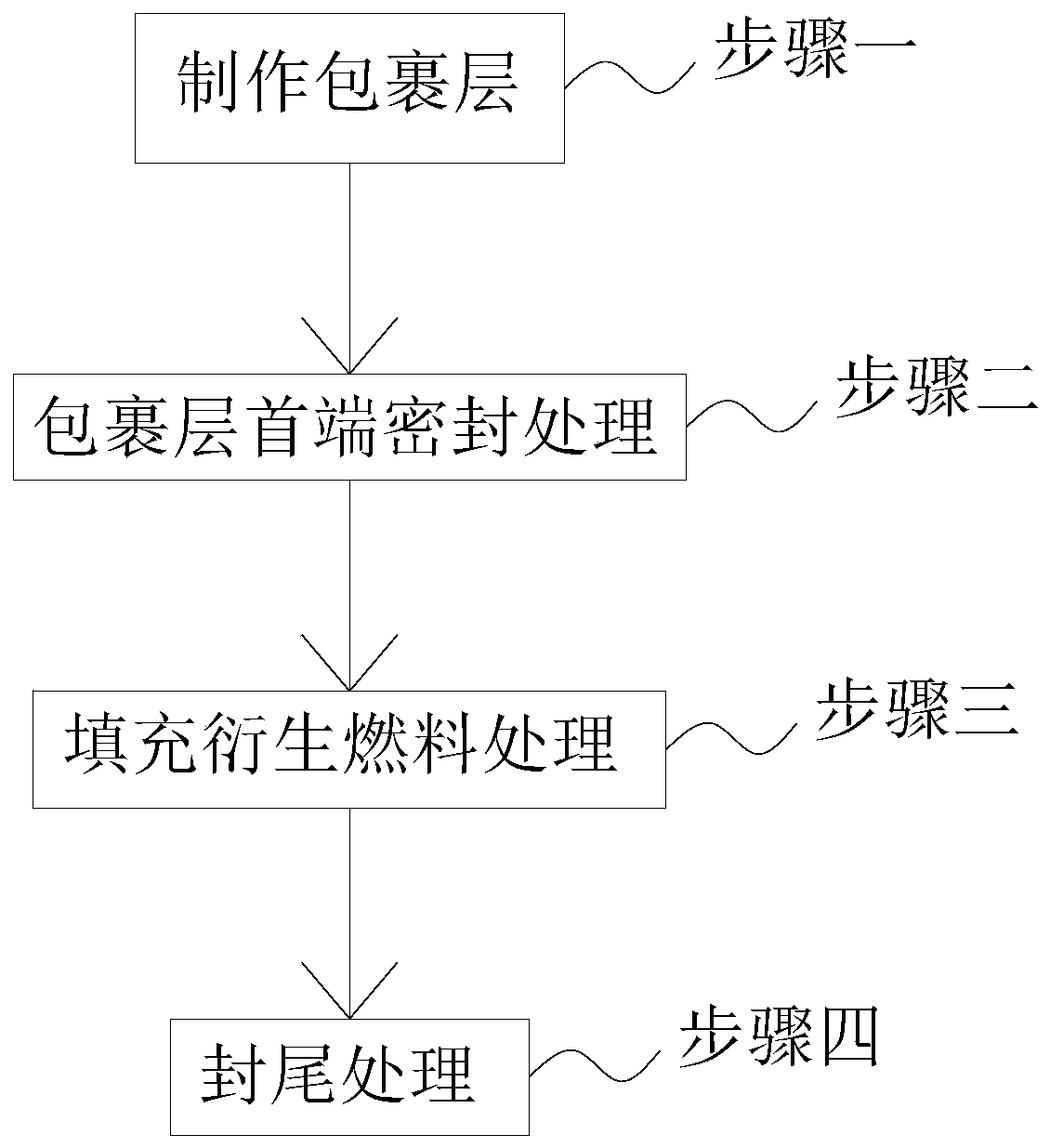

[0032] In order to achieve the above purpose, an embodiment of the present invention provides a method for making a garbage-derived fuel package. Such as figure 1 As shown, a method for making a garbage-derived fuel package, comprising:

[0033] Step 1: Make the wrapping layer, the plastic particles are melted into the extrusion head of the die, and extruded through the extrusion head of the die to form the wrapping layer;

[0034] Step 2: sealing the head end of the wrapping layer, cutting the wrapping layer extruded from the extrusion head of the die, and forming a closed end of the wrapped layer after cutting;

[0035] Step 3: Filling with derivative fuel treatment. While step 1 is being carried out, the combustible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com