Method and device for controlling pressure during aerated dual-gradient drilling for riser

A riser and dual gradient technology, which is applied in the automatic control system of drilling, drilling equipment, earth-moving drilling and production, etc., can solve the problems of stuck drilling, inability to effectively change the bottom hole pressure, drilling fluid leakage, etc., and achieve increased pressure regulation The effect of range, increased adjustment precision and timely responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

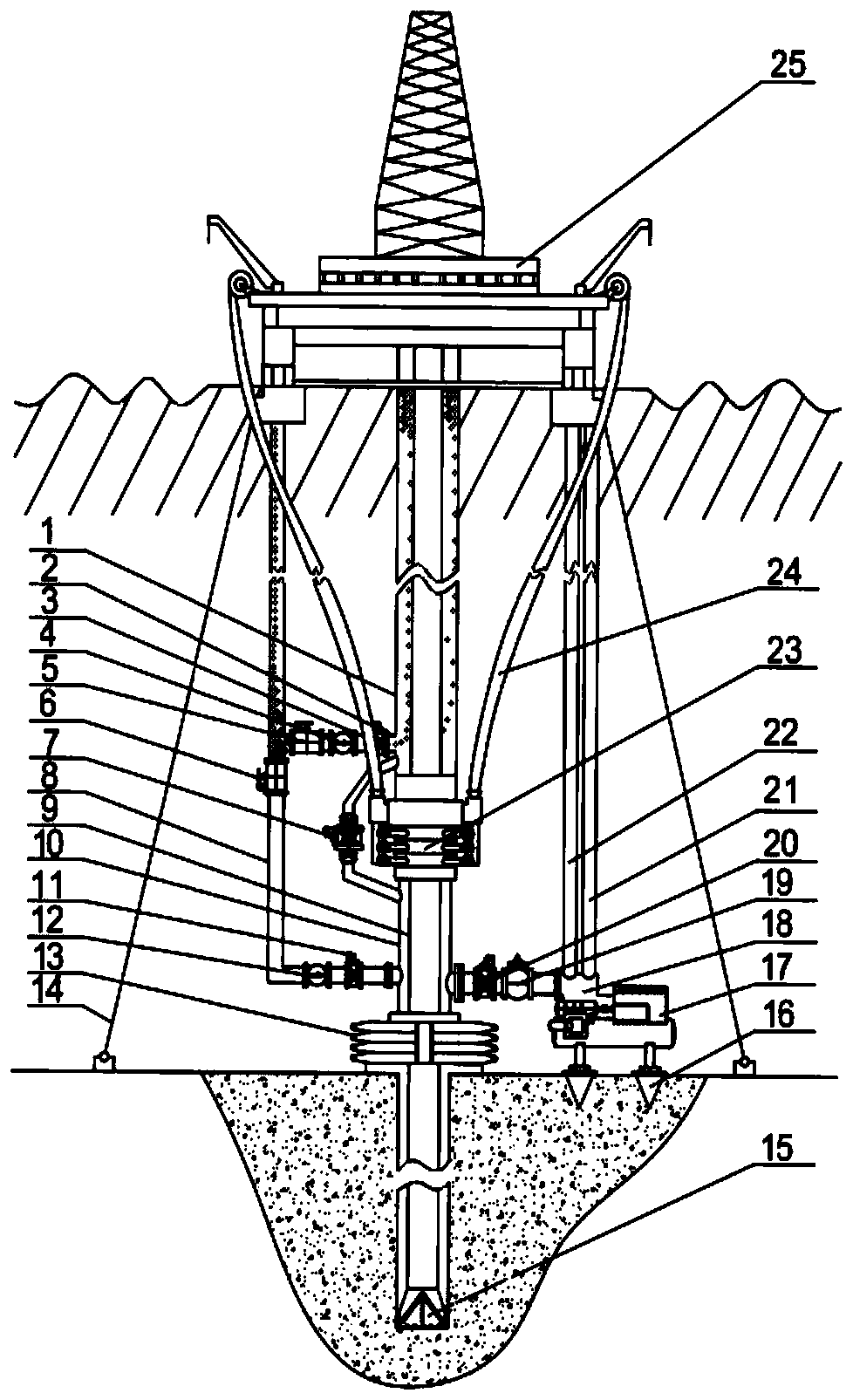

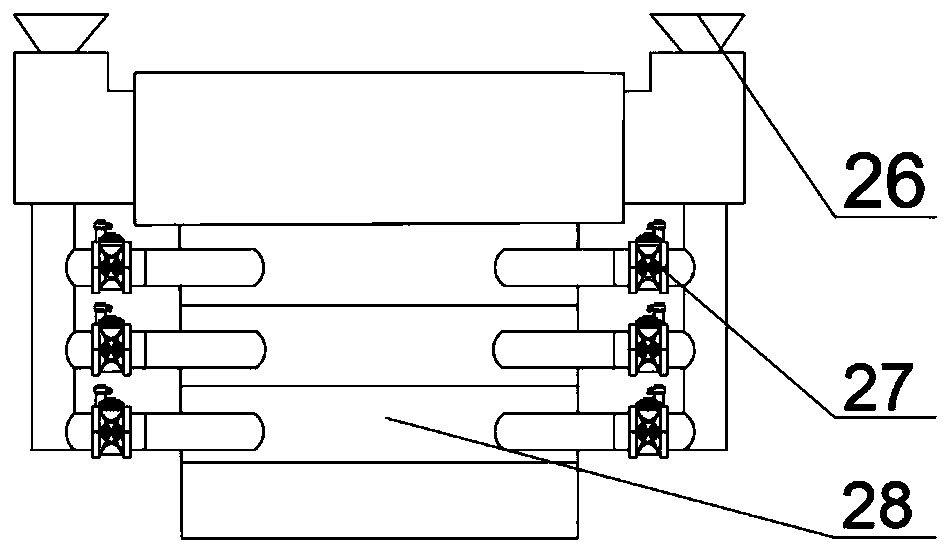

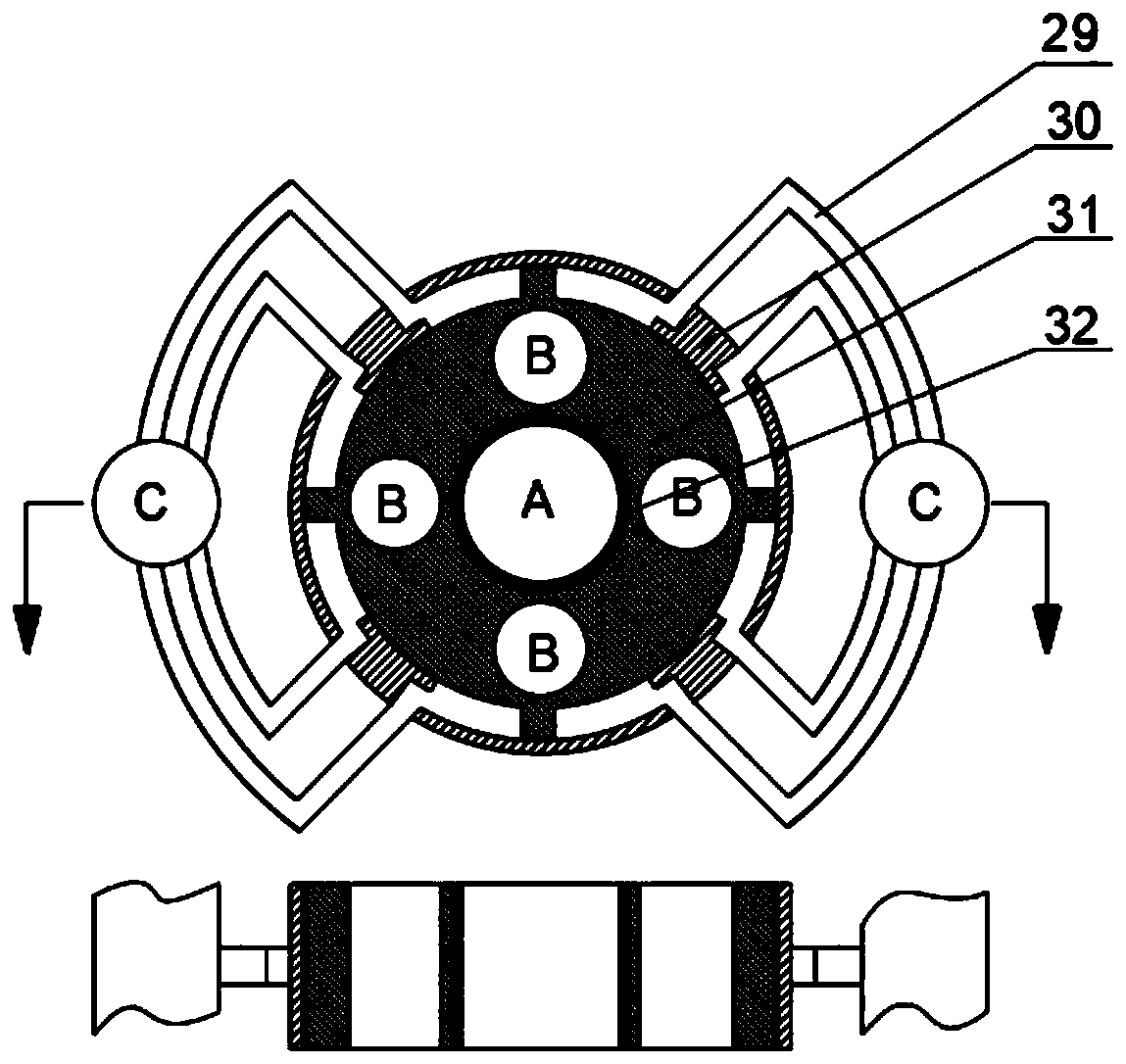

[0018] Such as Figure 1-Figure 5 As shown, a method and device for controlling pressure in riser-inflated dual-gradient drilling are schematically composed of an upper riser 1, an emergency shut-off solenoid valve A2, an upper gas injection channel 3, a one-way valve A4, and an automatic high-pressure control valve A5 , automatic high-pressure control valve B6, balance communication device 7, lower gas injection channel 8, drill pipe 9, lower riser 10, emergency shut-off solenoid valve B11, one-way valve B12, blowout preventer 13, fixed chain 14, drill bit 15, Fixer 16, monitoring and analysis module 17, subsea high-pressure pump 18, voltage stabilizer 19, emergency cut-off solenoid valve C20, booster pipeline 21, pressure-reducing pipeline 22, locking device 23, high-pressure hydraulic oil delivery pipe 24 and drilling platform 25, characterized in that: the upper riser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com